Novel uniform temperature liquid cold plate

A liquid-cooled plate, a new type of technology, applied in electrochemical generators, electrical components, batteries, etc., can solve the problems of heavy weight and large installation space of water-cooled plates, and achieve the effect of reducing temperature difference, reasonable structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

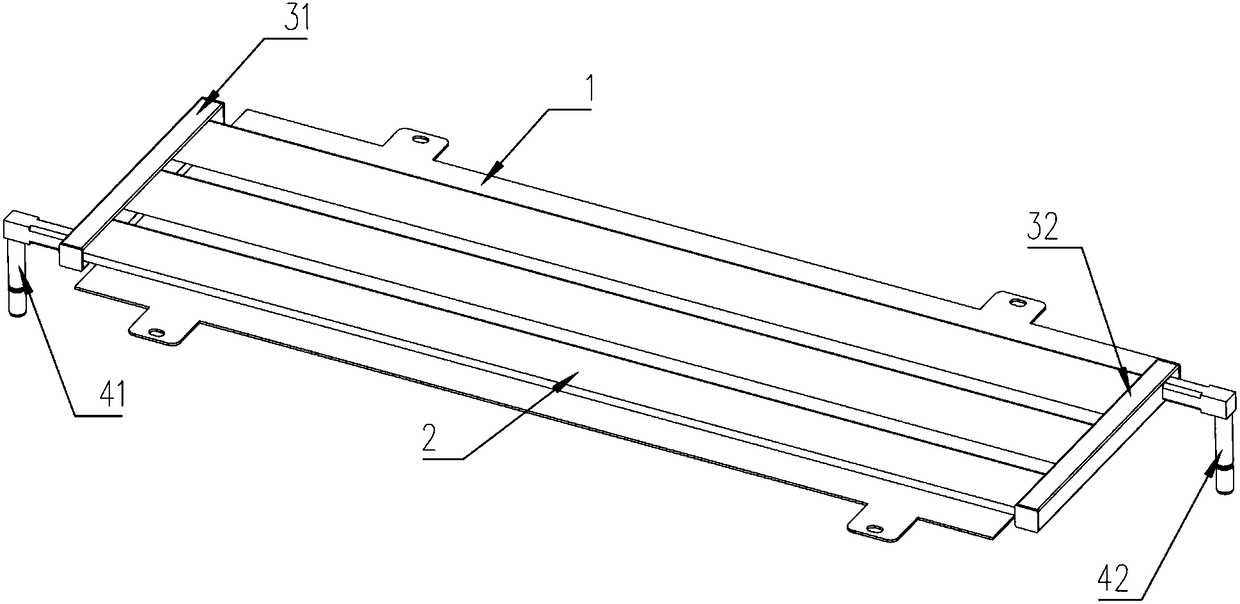

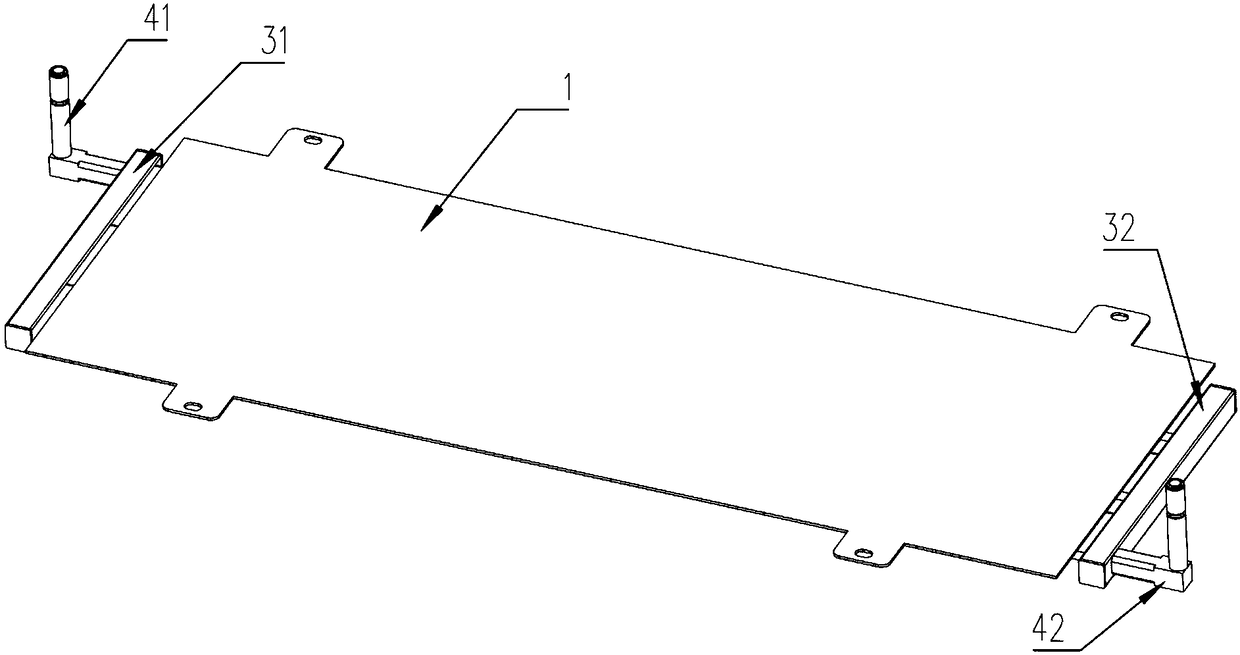

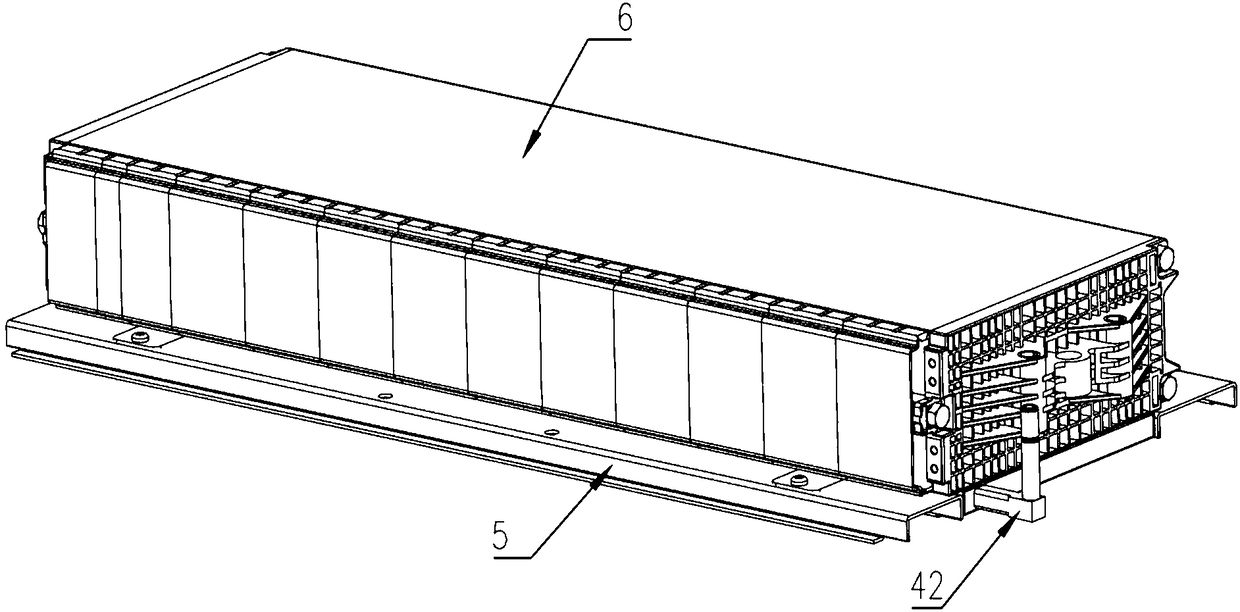

[0033] Such as Figure 1 to Figure 4 As shown, a new uniform temperature liquid cold plate described in this embodiment, the liquid cold plate includes a heat conduction fixed plate 1, a plurality of flow guide pipes 2, and two confluence pipes, the two ends of the confluence pipes are closed, and the two confluence pipes They are the inlet confluence pipe 31 and the outlet confluence pipe 32 respectively. The inlet confluence pipe 31 is provided with a liquid inlet, and the outlet confluence pipe 32 is provided with a liquid outlet. Several diversion pipes 2 are connected to the two confluence pipes. 2 is arranged on one surface of the heat conduction fixing plate 1, and the other side of the heat conduction fixing plate 1 is in close contact with the battery module 6.

[0034] Specifically, the liquid cold plate is composed of a heat conduction fixed plate 1, a diversion pipe 2, and a confluence pipe. The pipe 2 is arranged between two confluence pipes, the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com