A kind of preparation method of graphene carbon nanotube composite conductive framework for lithium-sulfur battery

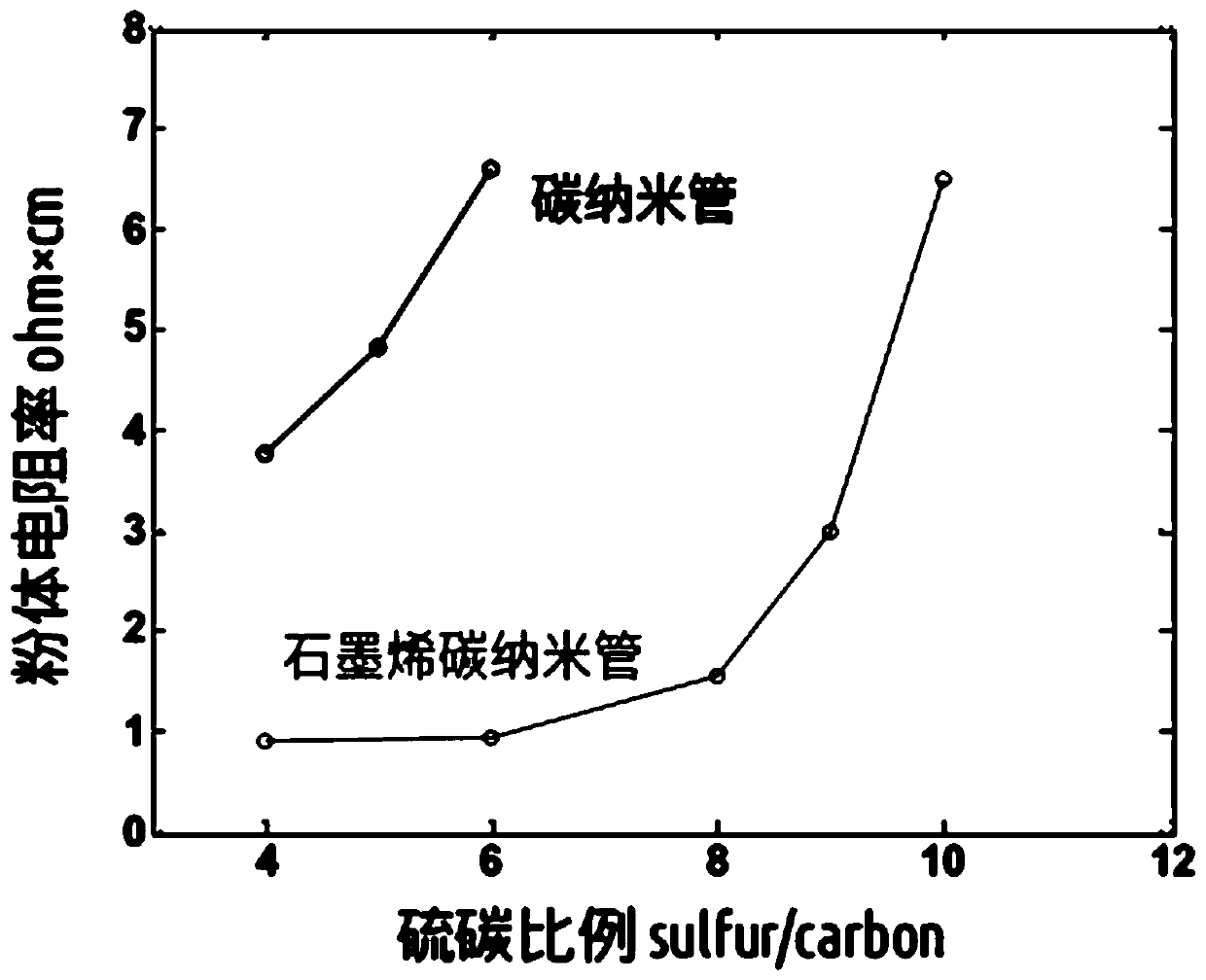

A nanotube composite, graphene carbon technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc. It can achieve good synergistic effect, improve energy density and active material utilization rate, and the process steps are simple and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a graphene carbon nanotube composite conductive framework for lithium-sulfur batteries.

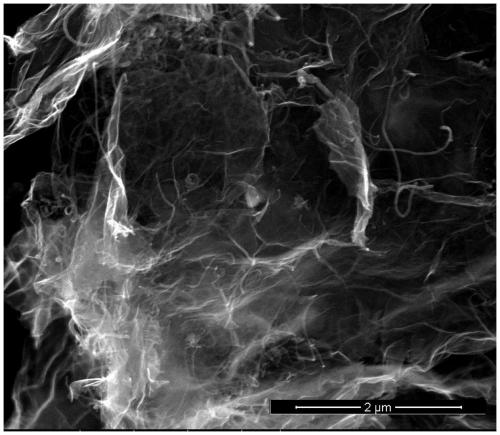

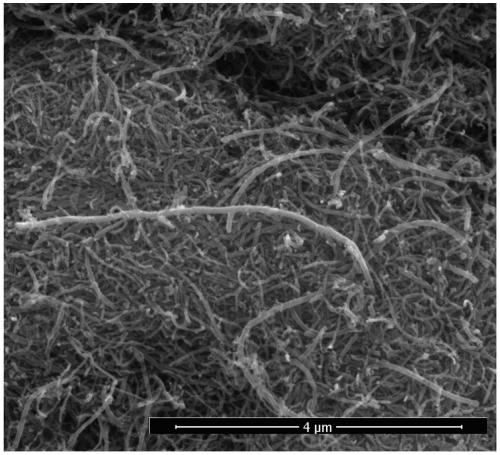

[0031] In the first step, the graphene oxide and carbon nanotube powders are obtained by using a shear dispersion method, and then mixed slurry is prepared, and the solid content of the slurry is less than 30%wt.

[0032] The shear dispersion method is one or more combinations of sand milling, homogeneous or ultrasonic dispersion. Graphene oxide is a single-layer or multi-layer graphene oxide obtained by oxidizing the poor layer of graphite.

[0033] The oxygen content of graphene oxide is 10%-60% by mass, preferably 25%-40% by mass.

[0034] In this embodiment, the specific implementation method of this step is: weighing 20 parts of graphene oxide and 20 parts of carbon nanotubes, adding them to 120 parts of deionized water, and performing sanding cycle treatment in a sand mill to obtain a mixed slurry.

[0035] In the second step, a surfactant is added to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com