A Circulating Fluidized Bed Roasting Activation Rotary Cogeneration Furnace

A circulating fluidized bed, roasting and activation technology, applied in the fields of environmental protection and resource recycling, can solve the problems that the temperature conditions of the roasting activation process cannot be met, and there is no mention of the comprehensive utilization of coal-fired fly ash in a circulating fluidized bed. The effects of avoiding emissions, reducing production costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

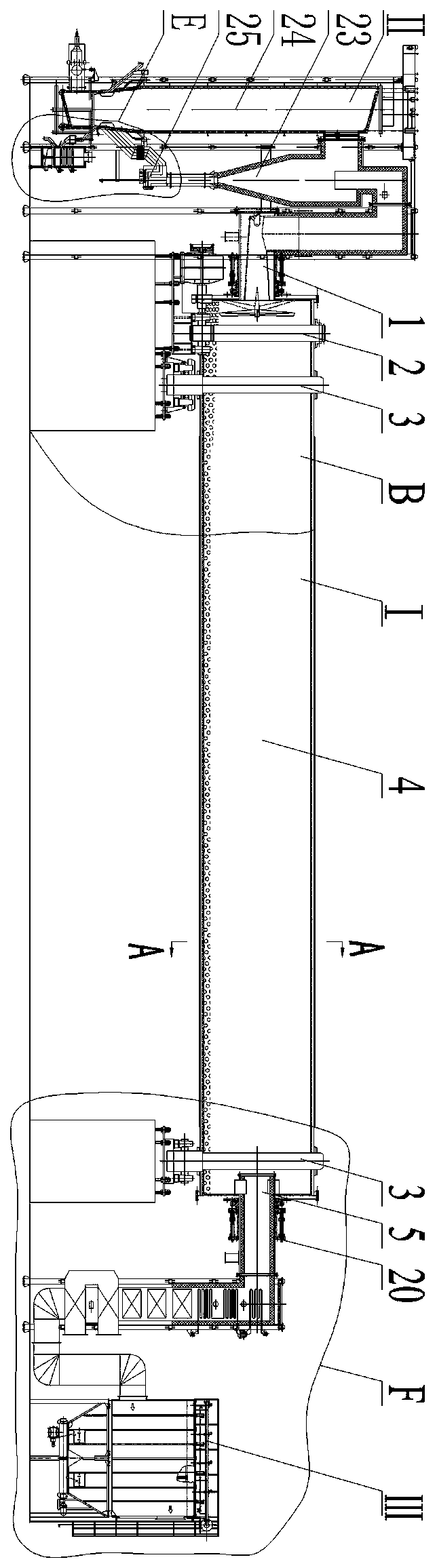

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a circulating fluidized bed roasting activation rotary co-production furnace is characterized in that it includes roasting activation rotary furnace I, circulating fluidized bed coal-fired boiler II, and electric bag dust collector III.

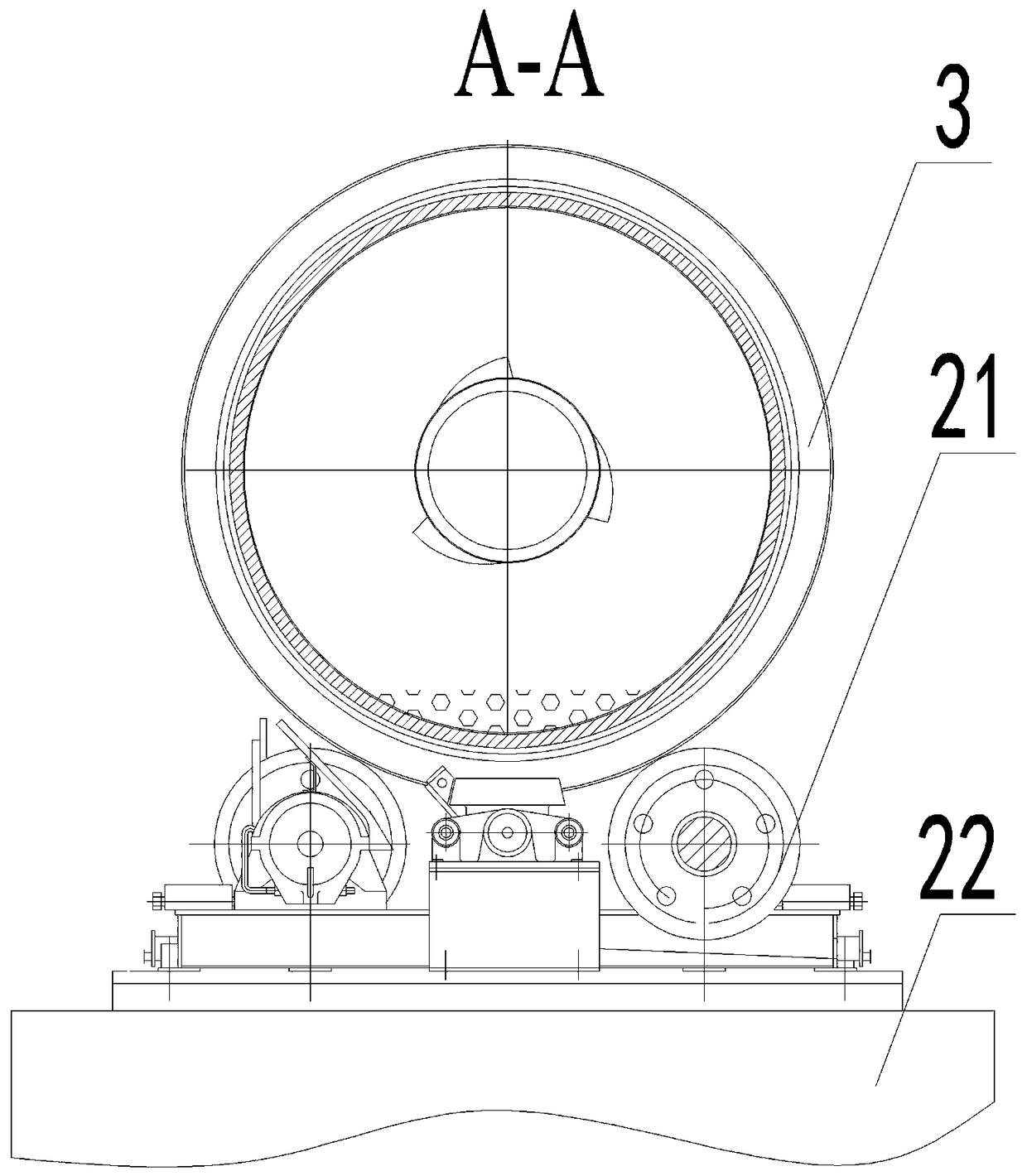

[0047] The roasting activation rotary furnace I includes a distributor 1 , a drive gear assembly 2 , an idler roller assembly 3 , a roasting activation rotary furnace cylinder assembly 4 , and an air separator 5 .

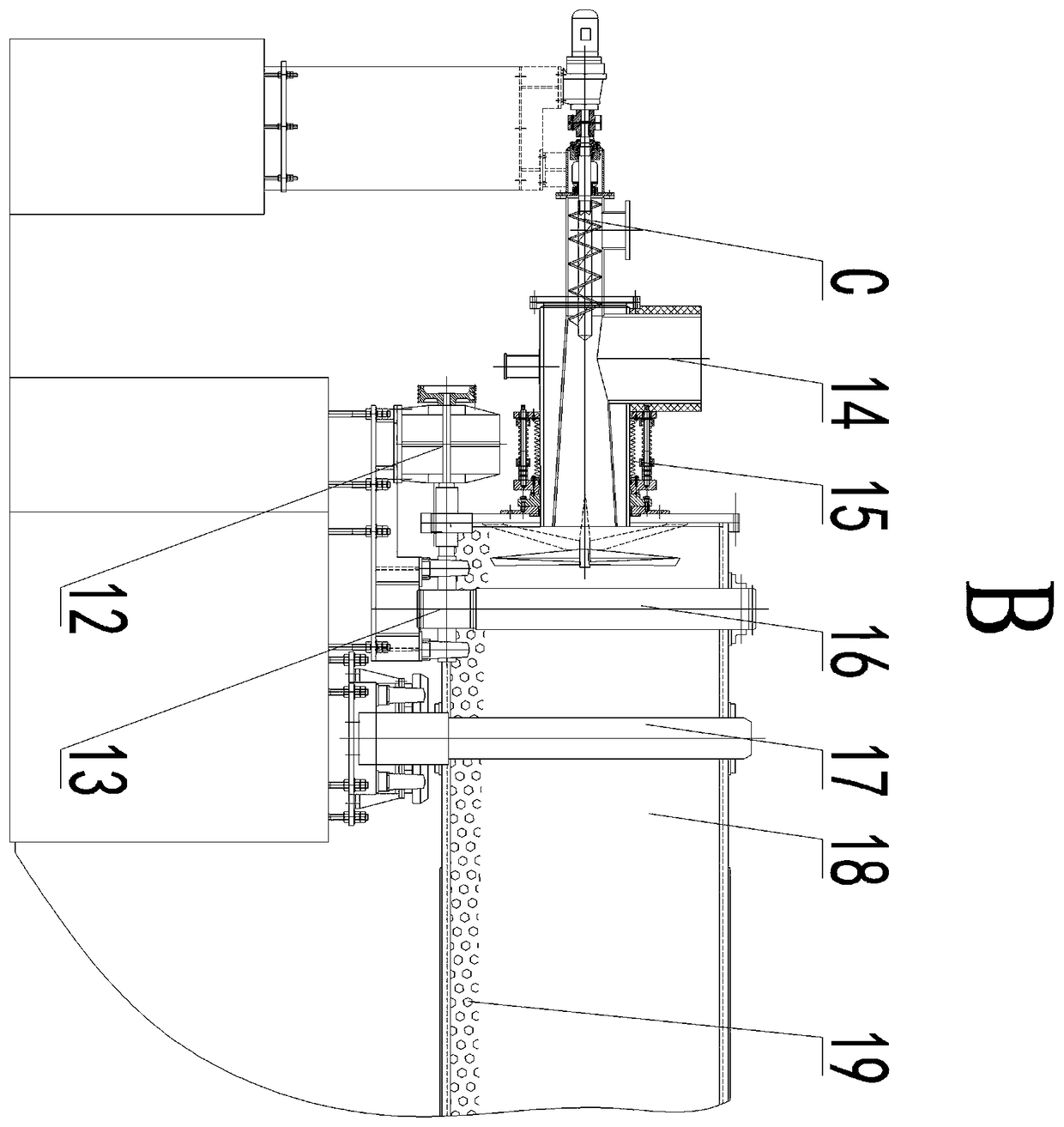

[0048] The distributor 1 includes a screw conveyor 6 , an injector 7 , a cooling jacket 8 , a splitter cone 9 , a spacer 10 , a worm blade 11 , and a hot air duct 14 . The screw conveyor 6 is connected with the injector 7, and the splitter cone 9 and the scroll blade 11 are fixed on the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com