Method for producing ethylene cracking material through liquefied gas hydrogenation

A technology for ethylene cracking and liquefied gas, which is applied in the processing of gas mixtures, hydrocarbon oil treatment products, petroleum industry, etc. It can solve the problems of high olefin content, fast carbon deposition in the catalyst bed, and difficulty in achieving the quality of raw materials for steam cracking. Achieve the effect of realizing the conversion rate and controlling the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

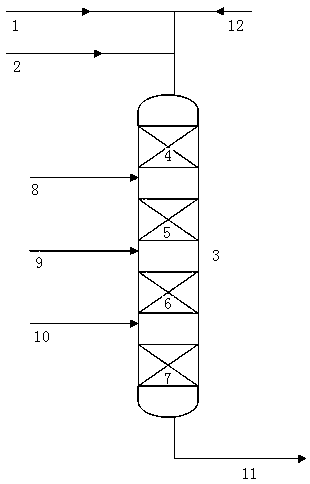

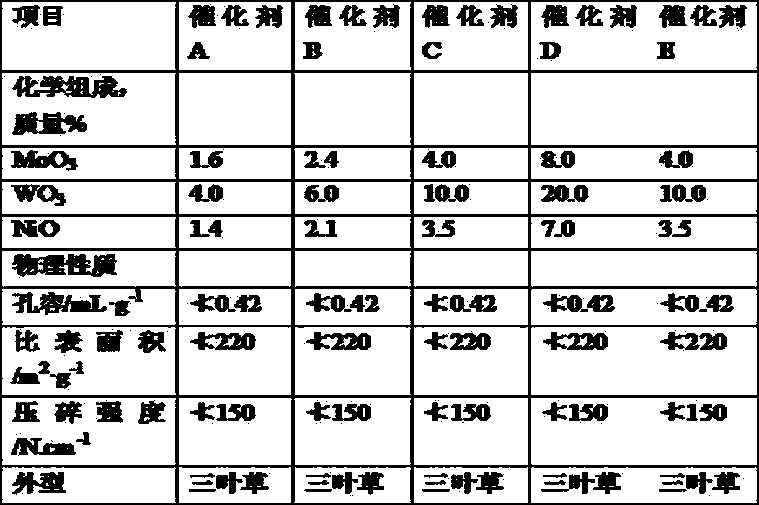

[0050] The reaction adopts a fixed-bed reactor with upper feed mode. The catalyst is packed in four stages, along the direction of material flow, in equal volume proportions. From top to bottom, the catalysts are A, B, C, D in sequence. The reaction process does not adopt a stepwise hydrogen feed scheme. The raw materials of hydrogen and liquefied gas enter the reactor from the inlet of the first reaction section. The physical properties of the catalyst used in the reaction are shown in Table 2. The catalyst needs to be vulcanized when in use, and the vulcanization operation is carried out by conventional vulcanization methods in this field, and will not be repeated. The reaction conditions and results are shown in Table 4. Table 5 shows the amount of coke deposited in each section of the catalyst bed after operation.

Embodiment 2

[0052] The reaction adopts a fixed-bed reactor with upper feed; the catalyst adopts four-stage packing, and is packed in equal volume ratio along the direction of material flow. From top to bottom, the catalysts are A, B, C, D in sequence. The reaction is divided into four stages to enter hydrogen, the amount of hydrogen entering the bed in each stage is: the amount of hydrogen entering the first catalyst bed in the first stage is 30v% of the chemical hydrogen consumption required for the reaction, and the second stage enters the second catalyst The amount of hydrogen in the bed is 30v% of the chemical hydrogen consumption required for the reaction, the amount of hydrogen entering the third catalyst bed in the third stage is 30v% of the chemical hydrogen consumption required for the reaction, and the fourth stage enters the fourth catalyst bed The amount of hydrogen is 50v% of the chemical hydrogen consumption required for the reaction. The physical properties of the catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com