Blue fluorescent powder for three-primary-color warm white LEDs and preparation method of blue fluorescent powder

A blue phosphor, warm white light technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of low color rendering index, increased cost of phosphors, and difficulty in matching warm colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

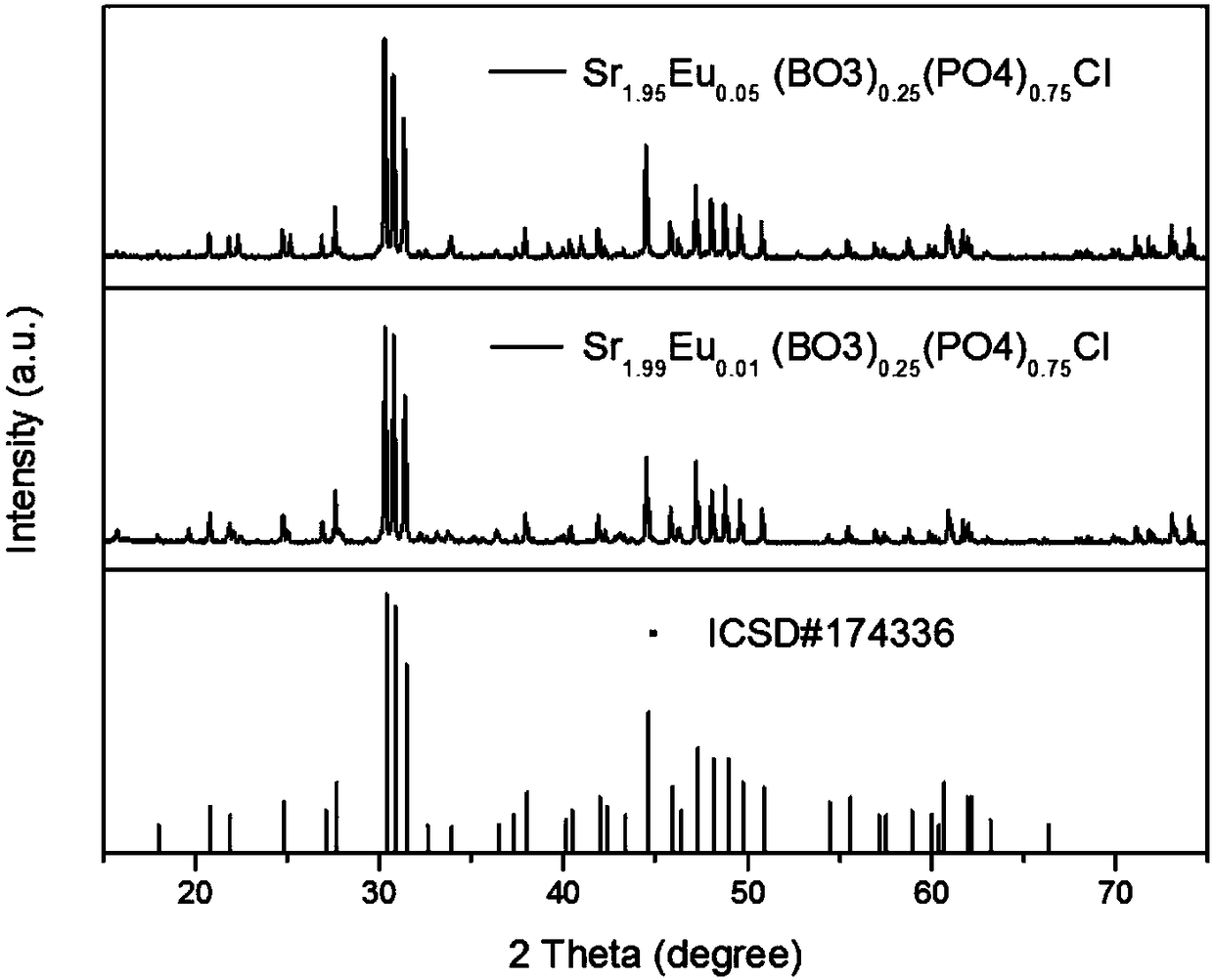

[0026] Strontium carbonate (SrCO 3 ), anhydrous ammonium chloride (NH 4 Cl), boric acid (H 3 BO 3 ), europium trioxide (Eu 2 o 3 ) and ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), placed in an agate mortar and thoroughly ground for 30 minutes and mixed evenly; the ground powder was roasted in a reducing atmosphere, heated to 1000°C at a heating rate of 5°C / min, sintered at this temperature for 6h, and cooled naturally to room temperature; the sample is taken out and ground to obtain a chemical formula of Sr 1.95 Eu 0.05 (BO 3 ) 0.25 (PO 4 ) 0.75 Cl phosphor. Its X-ray diffraction pattern (XRD) see figure 1 .

[0027] The raw material SrCO used in the embodiment of the present invention 3 (A.R.), NH 4 Cl(A.R.), H 3 BO 3 (A.R.), Eu 2 o 3 (99.99%) and NH 4 h 2 PO 4 (A.R.) are commercially available items.

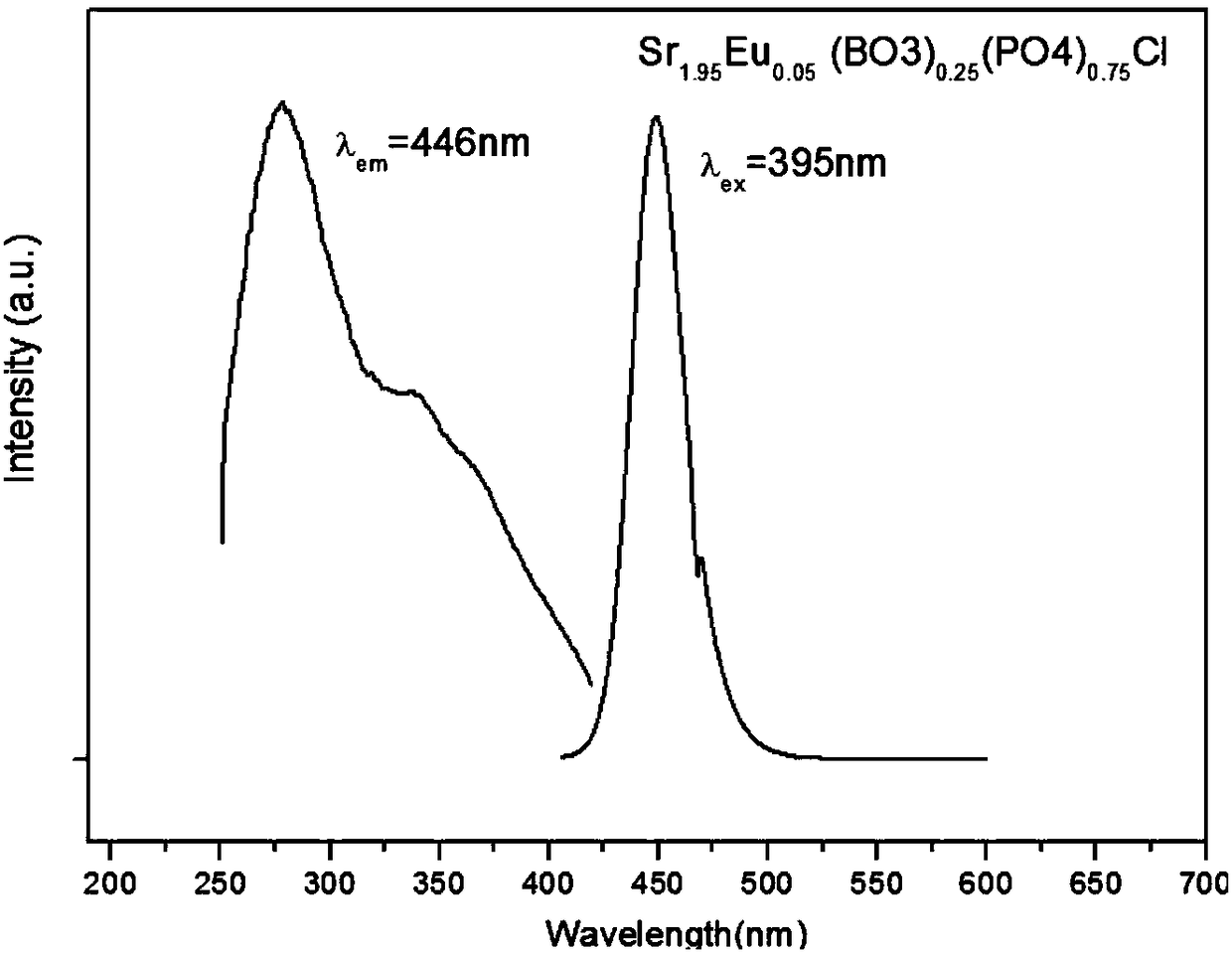

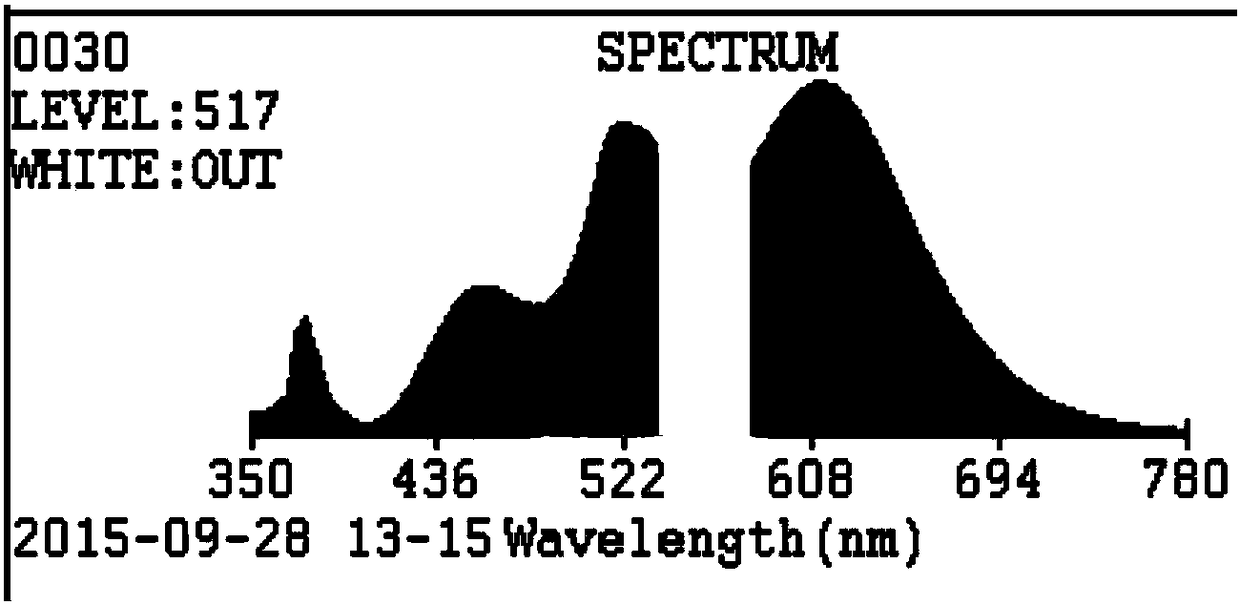

[0028] The prepared Sr 1.95 Eu 0.05 (BO 3 ) 0.25 (PO 4 ) 0.75 Cl phosphor, with CaAlSiN under violet excitation 3 : Eu 2+ Red phosphor and ...

Embodiment 2

[0031] It is basically the same as that of Example 1, except that the chemical formula of the prepared fluorescent powder is different. Its X-ray diffraction pattern (XRD) see figure 1 .

[0032] Strontium carbonate (SrCO 3 ), anhydrous ammonium chloride (NH 4 Cl), boric acid (H 3 BO 3 ), europium trioxide (Eu 2 o 3 ) and ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), placed in an agate mortar and thoroughly ground for 30 minutes and mixed evenly; the ground powder was roasted in a reducing atmosphere, heated to 1000°C at a heating rate of 5°C / min, sintered at this temperature for 6h, and cooled naturally to room temperature; the sample is taken out and ground to obtain a chemical formula of Sr 1.99 Eu 0.01 (BO 3 ) 0.25 (PO4 ) 0.75 Cl phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com