Composite solidifying agent and gas field three-sulfonated system waste drilling mud solidifying optimization method

A technology of composite curing agent and waste mud, which is applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc., can solve problems that cannot meet actual engineering needs, and achieve the effect of strengthening fixation and significant control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

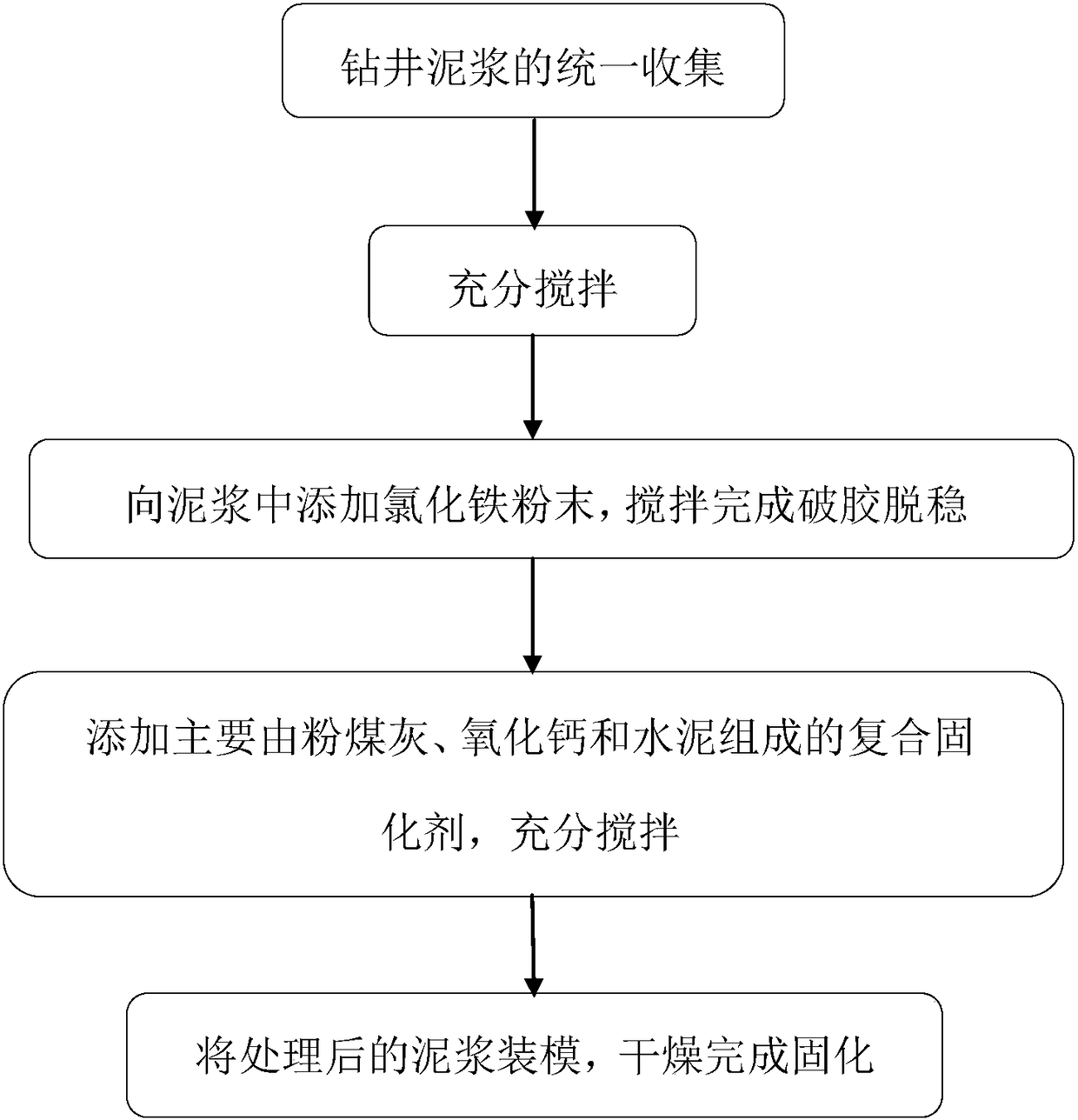

Method used

Image

Examples

Embodiment 1

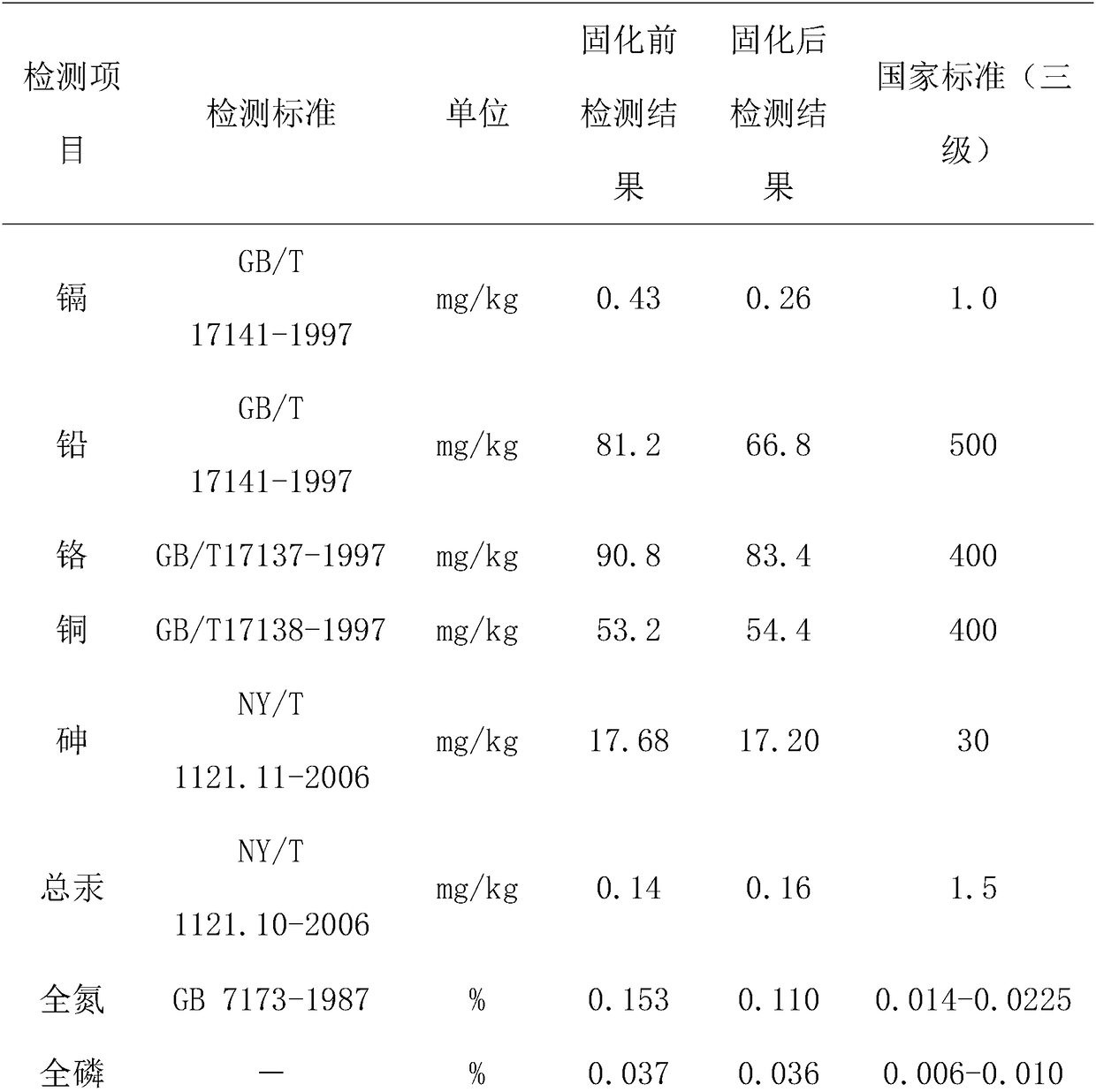

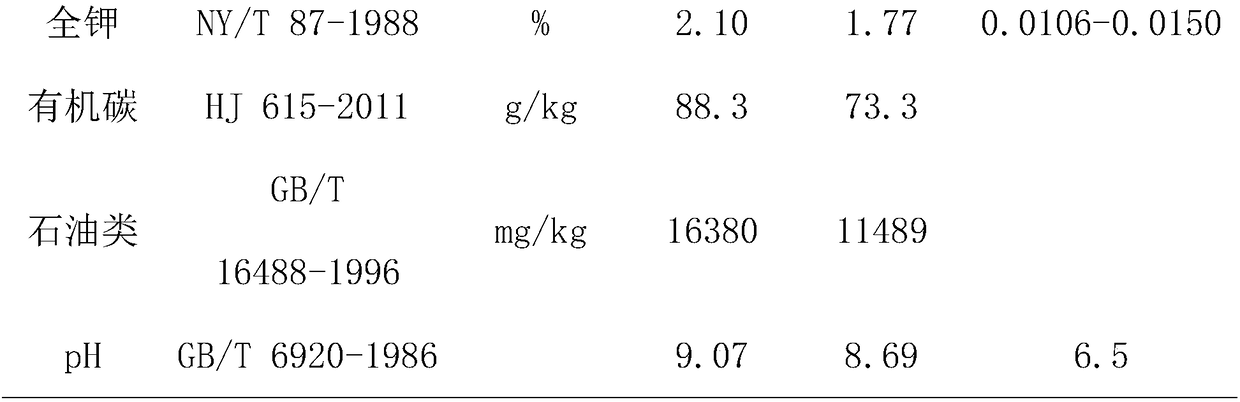

[0025] Embodiment 1: The research object of the present invention is the waste drilling mud from a certain gas field drilling in Tarim, which is mainly composed of cuttings, bentonite, weighting material calcium carbonate and ultrafine calcium carbonate, soda ash and caustic potash, potassium acrylate, tannin extract, etc. The particle size of the solid phase is generally between 0.01-0.03 μm, the appearance is viscous liquid or semi-fluid, an alkaline mixed liquid with extremely fine particles, high water content and not easy to dehydrate.

[0026] Firstly, 1.5% phenolic resin and 2% sulfonated asphalt were added to the drilling mud, and stirred with a stirrer until the solid-liquid components were fully mixed, so as to simulate the three-sulfur system drilling waste mud that appeared in the gas field.

[0027] And then carry out the pretreatment of destabilization of glue breaking. Add 6g / L ferric chloride (FeCl 3 ) powder, stir while adding, stir quickly for 3 minutes, and...

Embodiment 2

[0040] Embodiment 2: The research object of the present invention is the waste drilling mud from a certain gas field drilling in Tarim, which is mainly composed of cuttings, bentonite, weighting material calcium carbonate and ultrafine calcium carbonate, soda ash and caustic potash, potassium acrylate, tannin extract, etc. The particle size of the solid phase is generally between 0.01-0.03 μm, the appearance is viscous liquid or semi-fluid, an alkaline mixed liquid with extremely fine particles, high water content and not easy to dehydrate.

[0041] First, add 1% phenolic resin and 1% sulfonated asphalt into the drilling mud, and stir it with a stirrer until the solid-liquid components are fully mixed, so as to simulate the three-sulfur system drilling waste mud that appears in the gas field.

[0042] And then carry out the pretreatment of destabilization of glue breaking. Add 5g / L ferric chloride (FeCl 3 ) powder, stir while adding, stir rapidly for 4 minutes, and stir slowl...

Embodiment 3

[0045] Embodiment 3: The research object of the present invention is the waste drilling mud from a certain gas field drilling in Tarim, mainly composed of cuttings, bentonite, weighting material calcium carbonate and ultrafine calcium carbonate, soda ash and caustic potash, potassium acrylate, tannin extract, etc. The particle size of the solid phase is generally between 0.01-0.03 μm, the appearance is viscous liquid or semi-fluid, an alkaline mixed liquid with extremely fine particles, high water content and not easy to dehydrate.

[0046] First, add 2% phenolic resin and 3% sulfonated asphalt into the drilling mud, and stir it with a stirrer until the solid-liquid components are fully mixed, so as to simulate the three-sulfur system drilling waste mud that appears in the gas field.

[0047] And then carry out the pretreatment of destabilization of glue breaking. Add 8g / L ferric chloride (FeCl 3 ) powder, stir while adding, stir rapidly for 5 minutes, and stir slowly for 8 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com