High-pressure gravel rust removal device

A technology of sand and stone equipment, applied in the field of high-pressure sand and stone rust removal equipment, can solve the problems of inability to perform rust removal and anti-corrosion work, and easy to rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

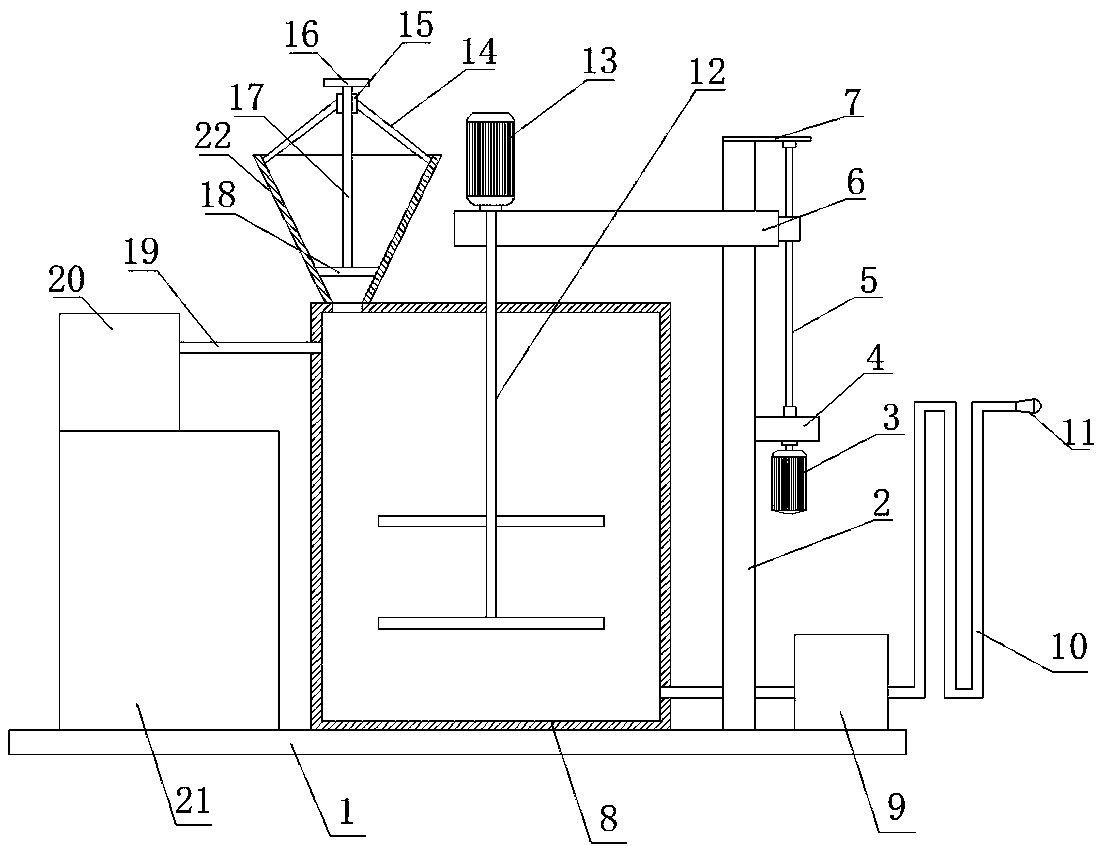

[0010] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0011] figure 1 Shown is the high-pressure sand and gravel derusting equipment provided by the present invention, including a base plate 1, a guide rod 2 is vertically provided on the upper end of the base plate 1, a screw rod 5 is provided on one side of the guide rod 2, and a lifting rod 5 is provided at the lower end of the screw rod 5. Motor 3; the guide rod 2 is provided with a lifting arm 6, and the lifting arm 6 can slide up and down along the guide rod 2; the lifting arm 6 is threadedly connected with the screw mandrel 5; A motor 13; a tank body 8 is provided above the base plate 1; the output shaft 12 of the stirring motor extends into the tank body 8, and a plurality of stirring blades are provided; a water tank 21 is arranged on the base plate 1, and the water tank 21 is configured A water pump 20 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com