Linear cutting machining method for straight swallowtail-type mortises

A processing method and wire cutting technology, which is applied in the field of straight dovetail tenon and groove processing of fan discs, can solve the problems of parts processing deformation, high manufacturing cost, and large number of milling cutters, and achieve reduced deformation, simple structure, and saving broach costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

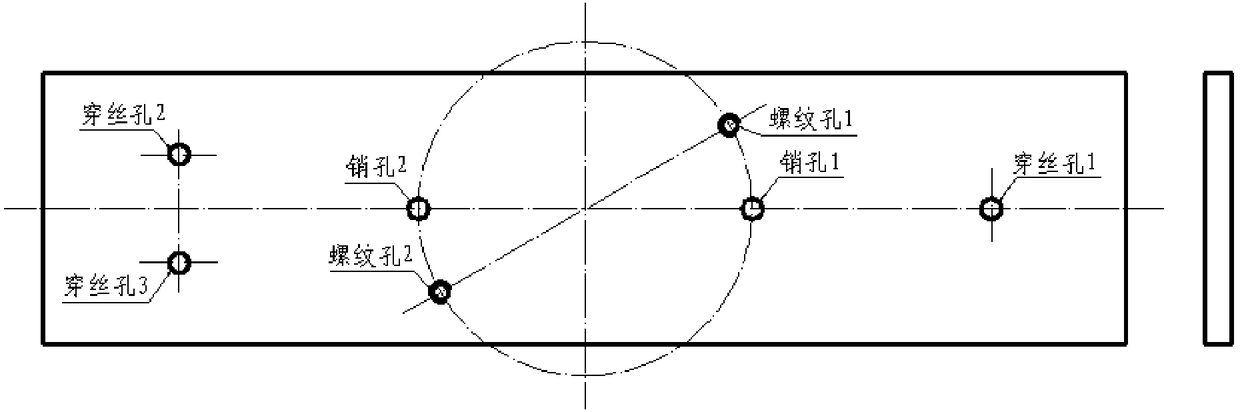

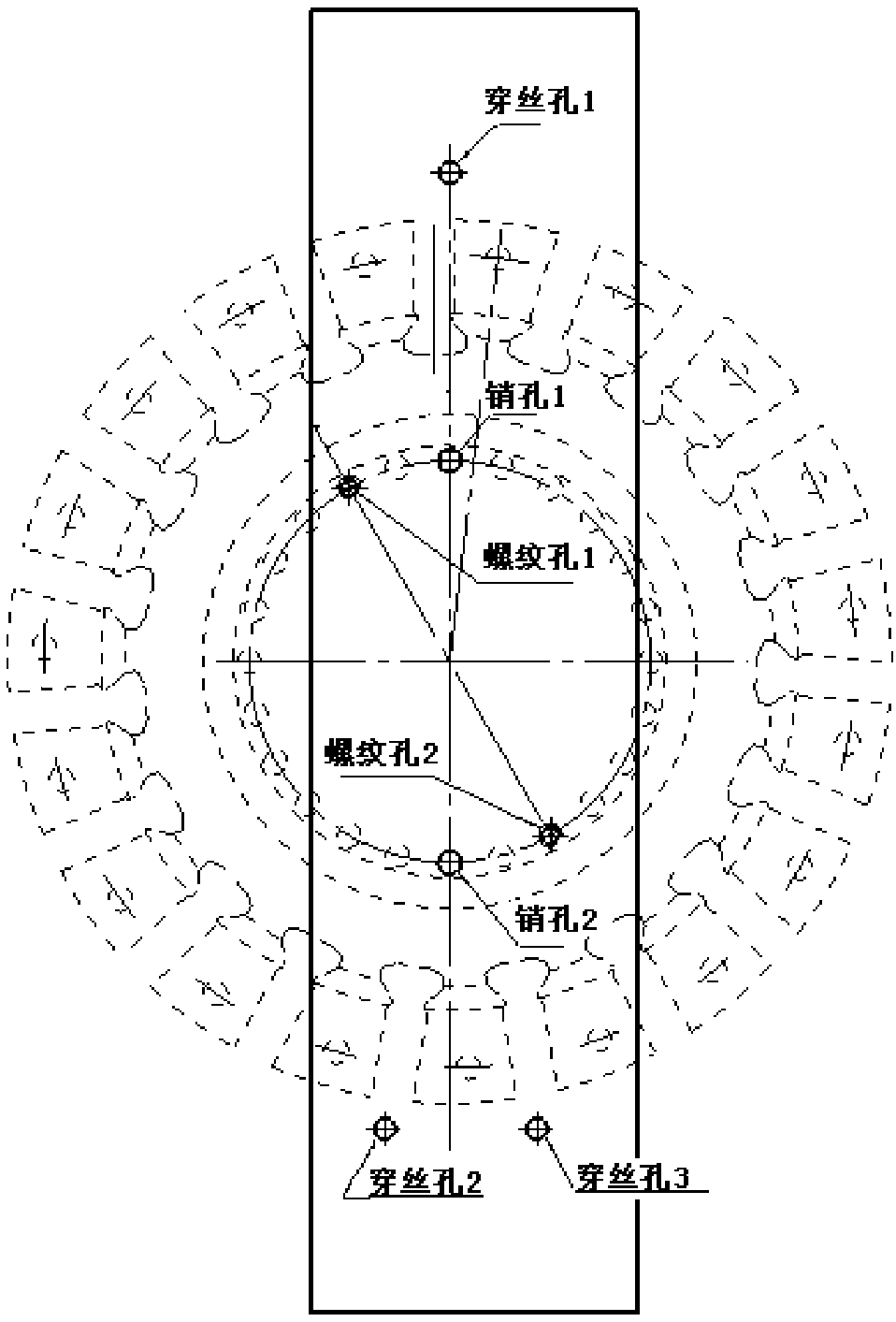

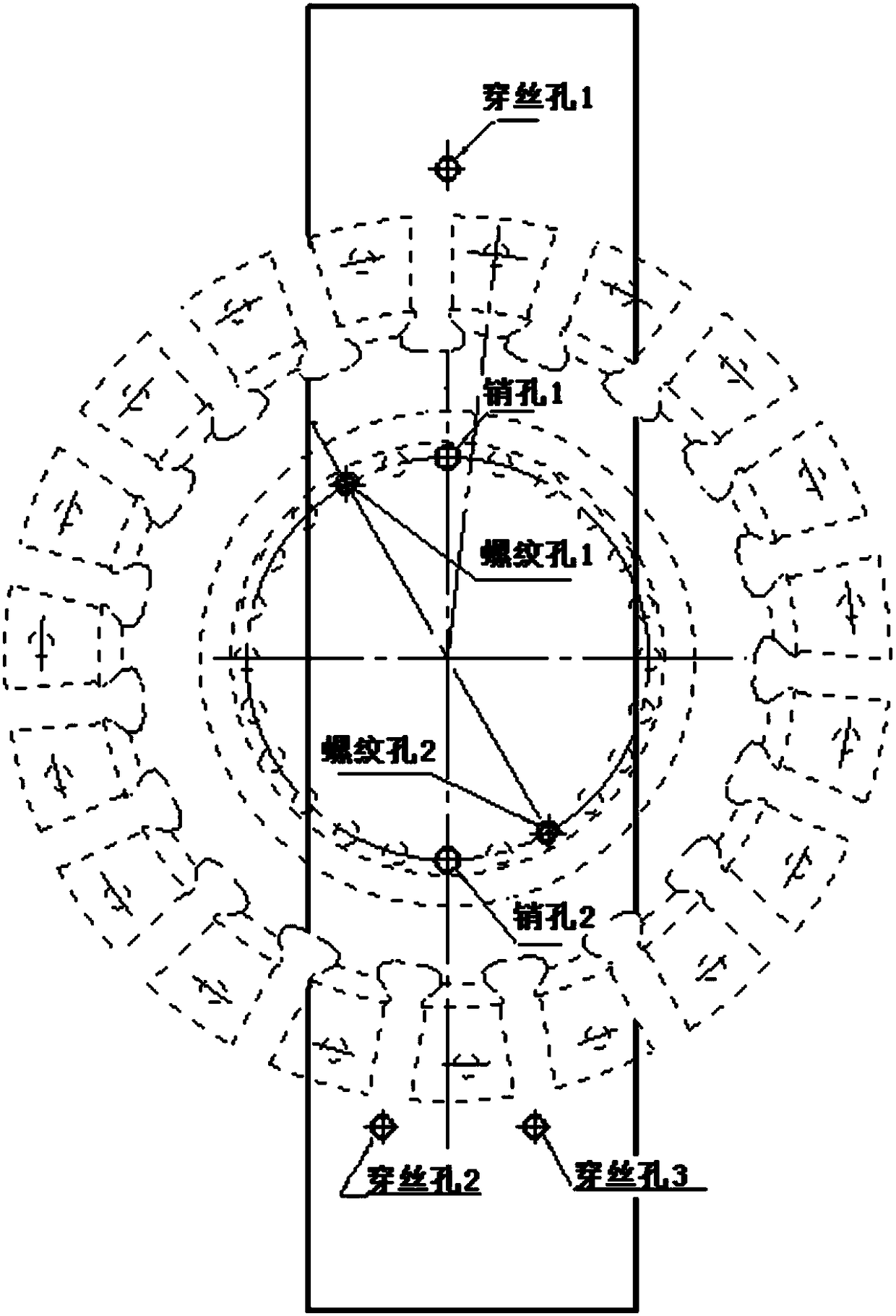

[0013] The following is attached with the manual Figure 1-3 The present invention is further described in detail.

[0014] A straight dovetail type tenon and groove wire cutting processing method, 1) using wire cutting to process the tenon and groove, first manufacturing a plurality of bottom plates;

[0015] 2) In order to make the bottom plate in step 1) adaptable to the versatility in the processing of different parts, a plurality of threading holes and a plurality of positioning holes are provided on the bottom plate according to several parts structures;

[0016] 3) The bottom plate is fixedly connected with the parts by bolts through the positioning holes; the bottom plate of the clamped parts is installed on the wire cutting machine, and the side of the bottom plate is used for straightening and alignment; all the tongues and grooves of the clamped parts can be processed at one time; There is no cutting force during processing, which can reduce the deformation of part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com