Method of manufacturing sulfide-based solid electrolyte through wet process

A solid electrolyte, sulfide technology, applied in the direction of solid electrolyte, sulfide conductor, electrolyte, etc., can solve the problems of uneven physical properties and uneven application of physical energy, and achieve the effect of low reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In addition to performing only the steps of the example (S 3 ) except for primary drying without secondary drying, a sulfide-based solid electrolyte containing nickel (Ni) element was produced by the same method as in Examples.

Embodiment 2

[0089] (1) Determination of Li 2 S:P 2 S 5 :Ni 3 S 2 The composition ratio of is 90mol:30mol:10mol to prepare 45g of the mixture.

[0090] (2) The mixture and 2300 g of zirconia balls were poured into a 1000 cc container of a planetary ball mill. The mixture was amorphized by milling for 20 hours.

[0091] (3) The amorphized mixture was crystallized by heat treatment at 260° C. for 2 hours to obtain a sulfide-based solid electrolyte containing nickel (Ni) element.

[0092] Evaluation of Physical Properties

[0093] (Amorphization Evaluation of Examples)

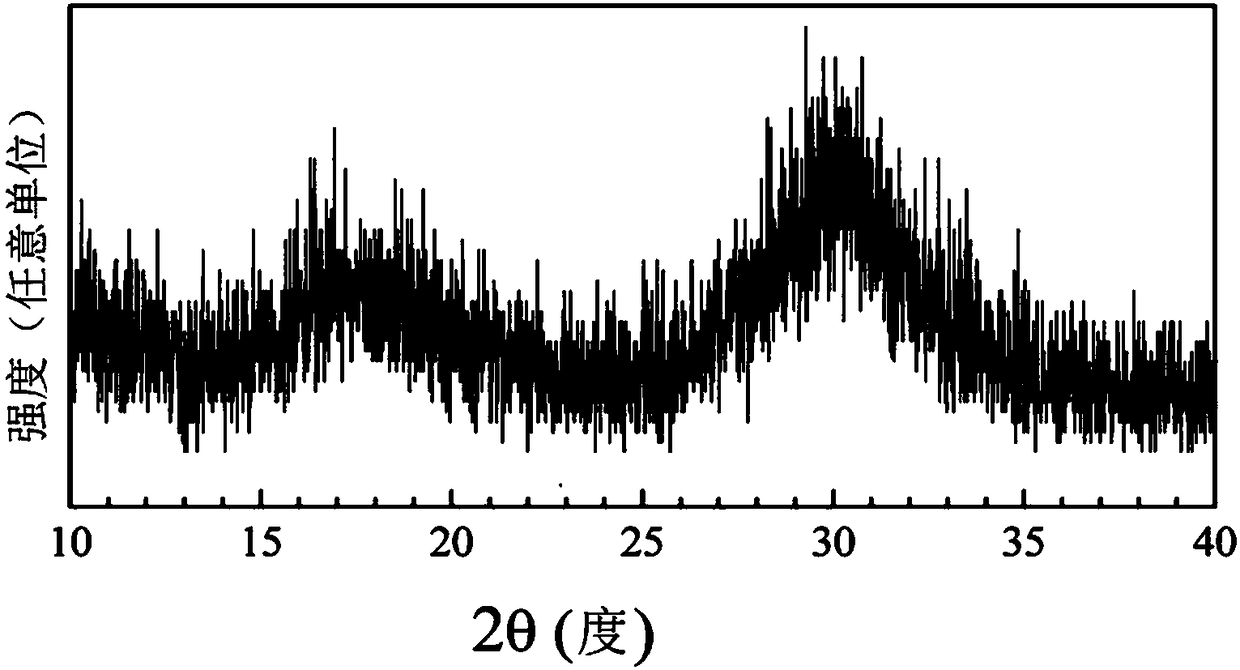

[0094] In manufacturing the sulfide-based solid electrolyte according to the example, when a solvent (xylene) was added so that the solid content of the slurry became 10% by weight, it was evaluated whether the mixture was amorphized by wet milling. To this end, X-ray diffraction spectroscopy (XRD) was performed on the mixture contained in the amorphized slurry. The result is shown in figure 1 middle.

[0095] refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com