Color steel tile fixture

一种彩钢瓦、夹具的技术,应用在光伏模块、太阳能集热器的固定底座/支架、可持续建筑等方向,能够解决施工成本高、削弱彩钢瓦整体强度、螺栓易松动等问题,达到加工和制造简单、效果稳定良好、适用范围广的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

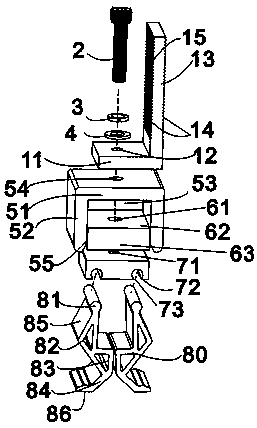

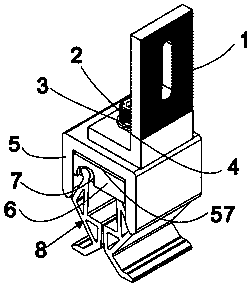

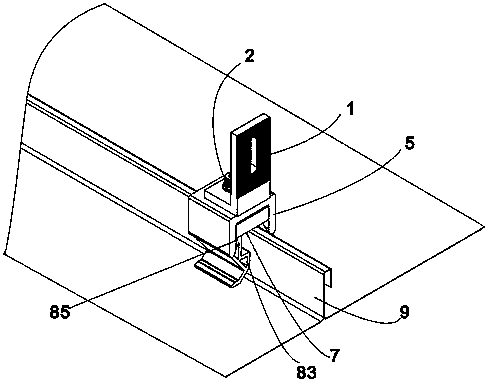

[0047] See figure 1 with figure 2 As shown, a color steel tile fixture includes an L-shaped connecting piece 1, a bolt 2, an elastic washer 3, a flat washer 4, an inverted U-shaped limiting piece 5, a stop block 6, a connecting block 7 and a clamp set 8.

[0048] The material of the limiting member 5, the clamping member group 8, the connecting block 7 and the connecting member 1 are all aluminum and made of aluminum. The horizontal end 11 of the connecting piece 1 is provided with a third through hole 12, and the vertical end 13 is provided with a wave-shaped surface 14 and a fourth through hole 15.

[0049] The limiting member 5 includes a horizontal plate 51 and two side plates 52 located at both ends of the horizontal plate. The two side plates 52 and the horizontal plate 51 enclose a limiting groove 53, and the two side plates 52 are grooves of the limiting groove 53. Arm 52; a first through hole 54 is provided on the horizontal plate 51. The inner end of the side plate 52 ...

Embodiment 2

[0064] Referring to Example 1, the difference from Example 1 is, see Figure 7 As shown, the connecting piece 1 of this embodiment is an I-shaped connecting piece, which is integrally connected to the horizontal plate 51. The connecting piece has a through hole 15 and a wavy surface 14.

Embodiment 3

[0066] Referring to Example 1, the difference from Example 1 is, see Figure 8 As shown, the connecting piece 1 of the present embodiment is a U-shaped piece 1 with a U-shaped groove 16. The U-shaped piece is integrally connected to the horizontal plate 51, and the U-shaped groove 16 is provided with a fifth through hole. 17. The fifth through hole 17 corresponds to the position of the first through hole 54 up and down. The bolt 2 passes through the fifth through hole 17, the first through hole 54 and the second through hole 61 in sequence, and then is screwed into the threaded hole 71.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com