Large vehicle fuel tank with fuel-shaking alleviating function

A technology for fuel tanks and large vehicles, applied in power units, vehicle parts, transportation and packaging, etc., can solve the problems of unsmooth fuel supply, large cumulative impact of sub-oil chambers, and excessive fuel tank volume, and achieve smooth fueling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

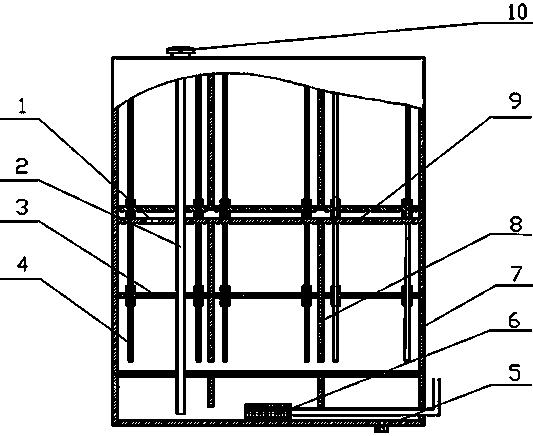

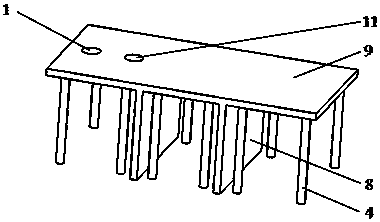

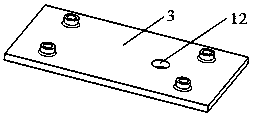

[0017] Such as figure 1 As shown, the structure of the fuel tank mainly includes: through hole 1, oil inlet pipe assembly 2, lightweight floating plate 3, guide column 4, oil discharge port 5, oil outlet pipe assembly 6, fuel tank shell 7, vertical partition Plate 8, horizontal partition 9, fuel tank cap 10. The upper end of the fuel inlet pipe assembly 2 is provided with an exhaust port, which is connected to the top of the fuel tank shell 7. The fuel tank cap 10 includes a pressure balance device; External connectivity. The horizontal partition 9 is welded on the fuel tank shell 7 in the horizontal direction, and divides the entire oil chamber into multiple vertically distributed secondary oil chambers, and only the horizontal partition between adjacent two secondary oil chambers The through hole 1 on the top is connected; the number of the horizontal partitions 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com