Method for bonding semiconductor chips to landing wafer

A semiconductor and chip technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as affecting the process and chip accuracy deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the detailed description that follows, a surface is said to be "wettable" by an alignment fluid when a volume of fluid applied to the surface spreads readily across the surface. The liquid can be water or any other suitable alignment fluid. A surface that is wettable by water is said to be hydrophilic.

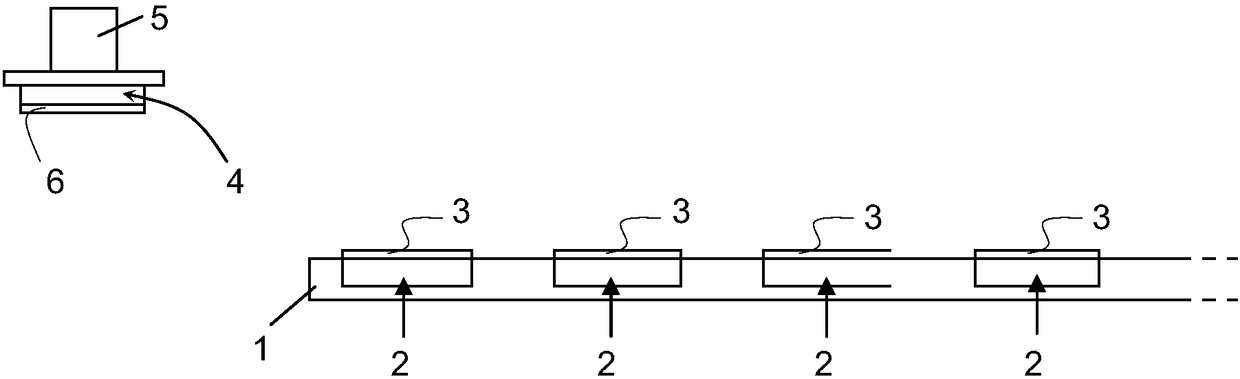

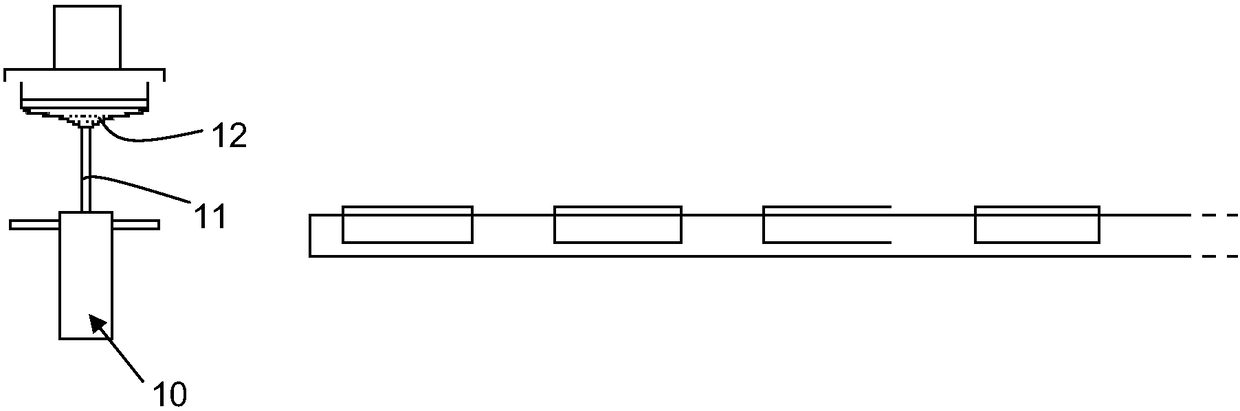

[0030] According to the method of the invention, the bonding surfaces of the bonding sites on chips and wafers can be at least partially wetted by a given alignment liquid, possibly made (more) wettable by plasma treatment, as known technology like that. However, in contrast to prior art methods, the method of the present invention includes the step of dispensing droplets of alignment fluid on the bonding surface of the chip before placing the chip on the wafer. Figures 1a to 1h The steps of a method according to a preferred embodiment are illustrated. A landed wafer 1 with a plurality of bonding locations 2 is provided ( Figure 1a ). These locations include an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com