Production technology of deformation-preventing composite ground heating floor

A production process and anti-deformation technology, applied in layered products, lamination devices, lamination auxiliary operations, etc., can solve problems such as deformation and easy cracking of the floor, achieve uniform heat transfer, prevent floor deformation, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

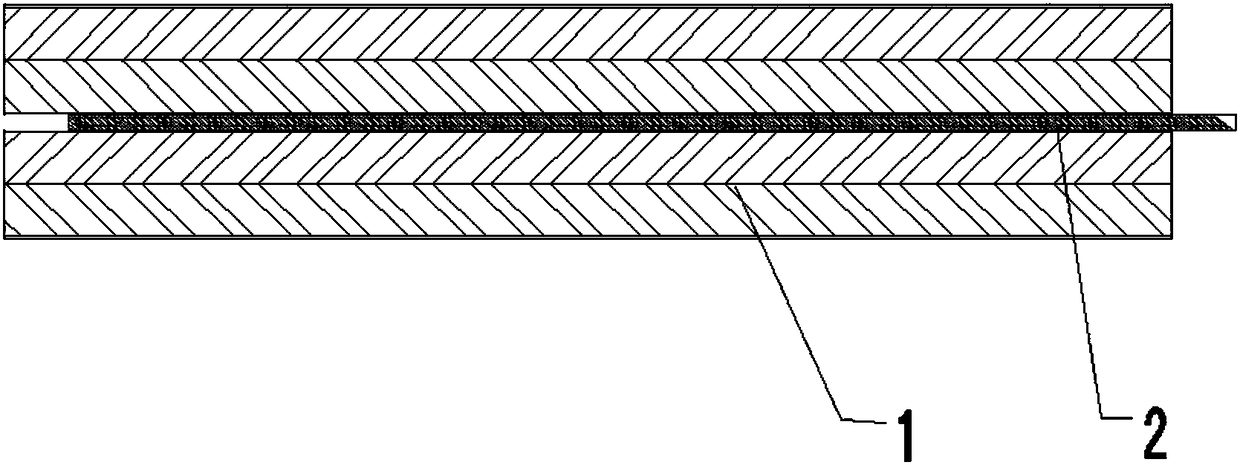

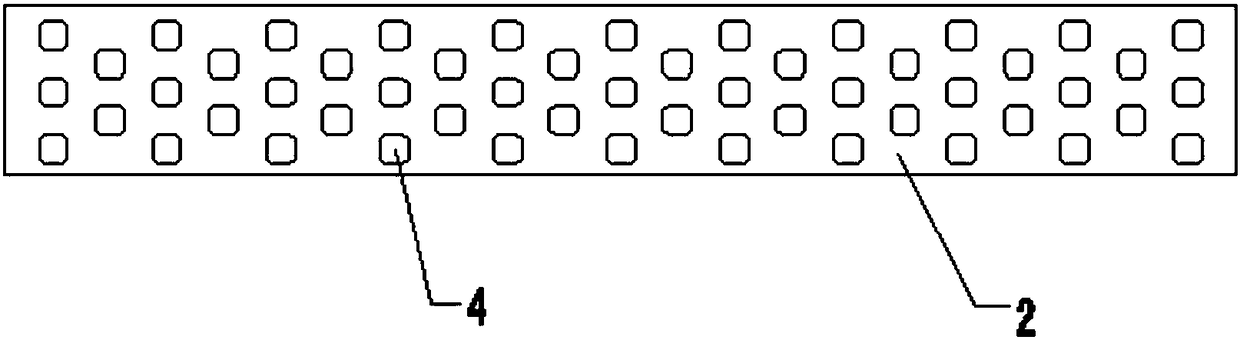

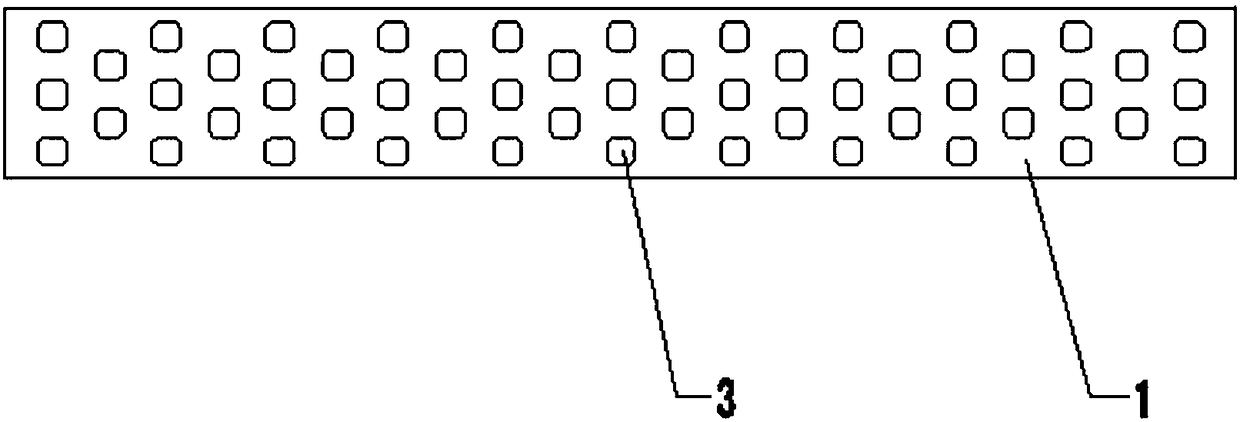

[0024] like figure 1 , figure 2 and image 3 In the shown embodiment, a production process of anti-deformation composite floor heating includes the following steps:

[0025] First cut the cold-rolled steel plate into the required specifications, and then form a number of punching holes evenly on the metal plate through die-opening stamping, and the punching holes run through the metal plate; Raised wooden boards, the positioning protrusions are adapted to the punching holes, the height of the positioning protrusions is 0.5mm, and the thickness of the metal plate is 1mm; finally, glue is applied to both sides of the metal plate and the raised side of the wood board, and on both sides of the metal plate, The wooden boards are respectively inserted into the punched holes at the corresponding positions on the metal boards through the positionin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com