Mastic fluorine paint and preparation method thereof

A technology of fluorine coatings and raw materials, which is applied in the field of thick-build fluorine coatings and its preparation, which can solve the problems of uneven coating surface thickness and difficult control of coating size, achieve excellent anti-corrosion performance, smooth film surface, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

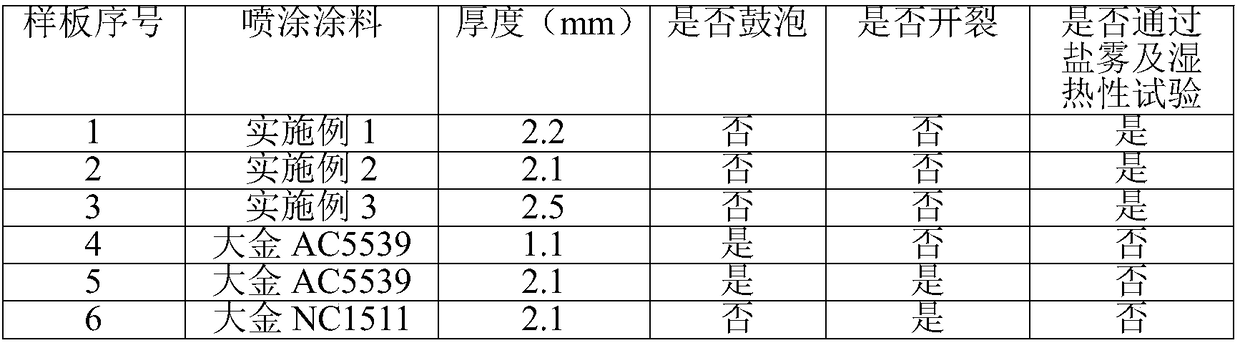

Examples

Embodiment 1

[0061] (1) 40 parts of fusible polytetrafluoroethylene, 10 parts of polytetrafluoroethylene resin, 8 parts of glycerol, 1.2 parts of fatty alcohol-ethylene oxide condensate, 2 parts of dibutyl phthalate and 1.7 parts of mica iron pearl powder were added to the reaction kettle, stirred, the speed of the stirrer was 600 rpm, and the time was 30 minutes;

[0062] (2) Add 3 parts of propylene glycol into 30 parts of water, stir, the stirring speed is 400 rpm, and the time is 20 minutes;

[0063] (3) Add the solution obtained in step (2) into the solution obtained in step (1), stir, the stirring speed is 600 rpm, and the time is 40 minutes;

[0064] (4) Add 1.8 parts of polysiloxane, 2 parts of sodium cetylphenyl sulfonate and 0.3 part of triethanolammonium to the solution obtained in step (3), stir, the stirring speed is 600 rpm, and the time is 60 minutes.

[0065] (5) Take a rectangular stainless steel plate, put it into a high-temperature oven with a constant temperature of 3...

Embodiment 2

[0072] (1) Mix 40 parts of fusible polytetrafluoroethylene, 10 parts of polyperfluoroethylene propylene resin, 8 parts of glycerol, 1.2 parts of fatty alcohol-ethylene oxide condensate, and 2 parts of dibutyl phthalate Add 1.7 parts of mica iron pearl powder to the reaction kettle, stir, the stirrer speed is 600 rpm, and the time is 30 minutes;

[0073] (2) Add 3 parts of propylene glycol into 30 parts of water, stir, the stirring speed is 400 rpm, and the time is 20 minutes;

[0074] (3) Add the solution obtained in step (2) into the solution obtained in step (1), stir, the stirring speed is 600 rpm, and the time is 40 minutes;

[0075] (4) Add 1.8 parts of polysiloxane, 2 parts of sodium cetylphenyl sulfonate and 0.3 part of triethanolammonium to the solution obtained in step (3), stir, the stirring speed is 600 rpm, and the time is 60 minutes.

[0076] (5) Take a rectangular stainless steel plate, put it into a high-temperature oven with a constant temperature of 380°C, k...

Embodiment 3

[0083] (1) 45 parts of fusible polytetrafluoroethylene, 5 parts of polyperfluoroethylene propylene resin, 8 parts of glycerol, 1.2 parts of fatty alcohol-ethylene oxide condensate, 2 parts of dibutyl phthalate Add 1.7 parts of mica iron pearl powder to the reaction kettle, stir, the stirrer speed is 600 rpm, and the time is 30 minutes;

[0084] (2) Add 3 parts of propylene glycol into 30 parts of water, stir, the stirring speed is 400 rpm, and the time is 20 minutes;

[0085] (3) Add the solution obtained in step (2) into the solution obtained in step (1), stir, the stirring speed is 600 rpm, and the time is 40 minutes;

[0086] (4) Add 1.8 parts of polysiloxane, 2 parts of sodium cetylphenyl sulfonate and 0.3 part of triethanolammonium to the solution obtained in step (3), stir, the stirring speed is 600 rpm, and the time is 60 minutes.

[0087] (5) Take a rectangular stainless steel plate, put it into a high-temperature oven with a constant temperature of 380°C, keep the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com