Preparation method of high-strength concrete

A concrete, high-strength technology, applied in chemical instruments and methods, screens, grids, etc., can solve the problems of difficulty in processing high-quality concrete, affecting the firmness of buildings, and high equipment investment costs, achieving long service life, mixing The effect of high uniformity and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

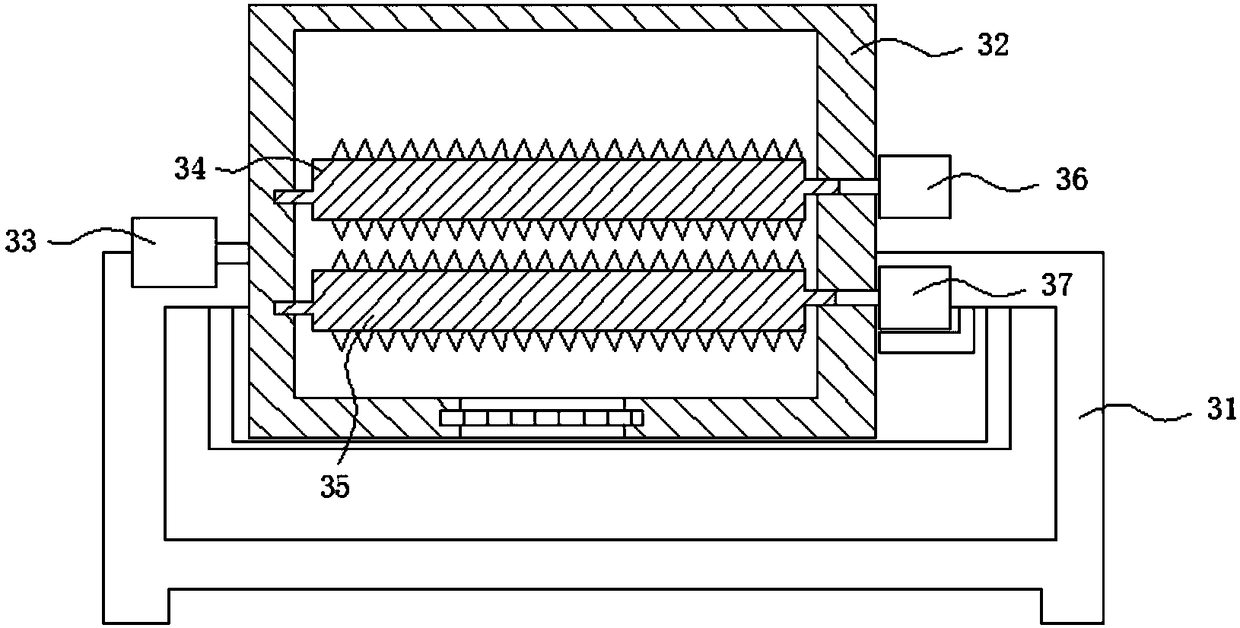

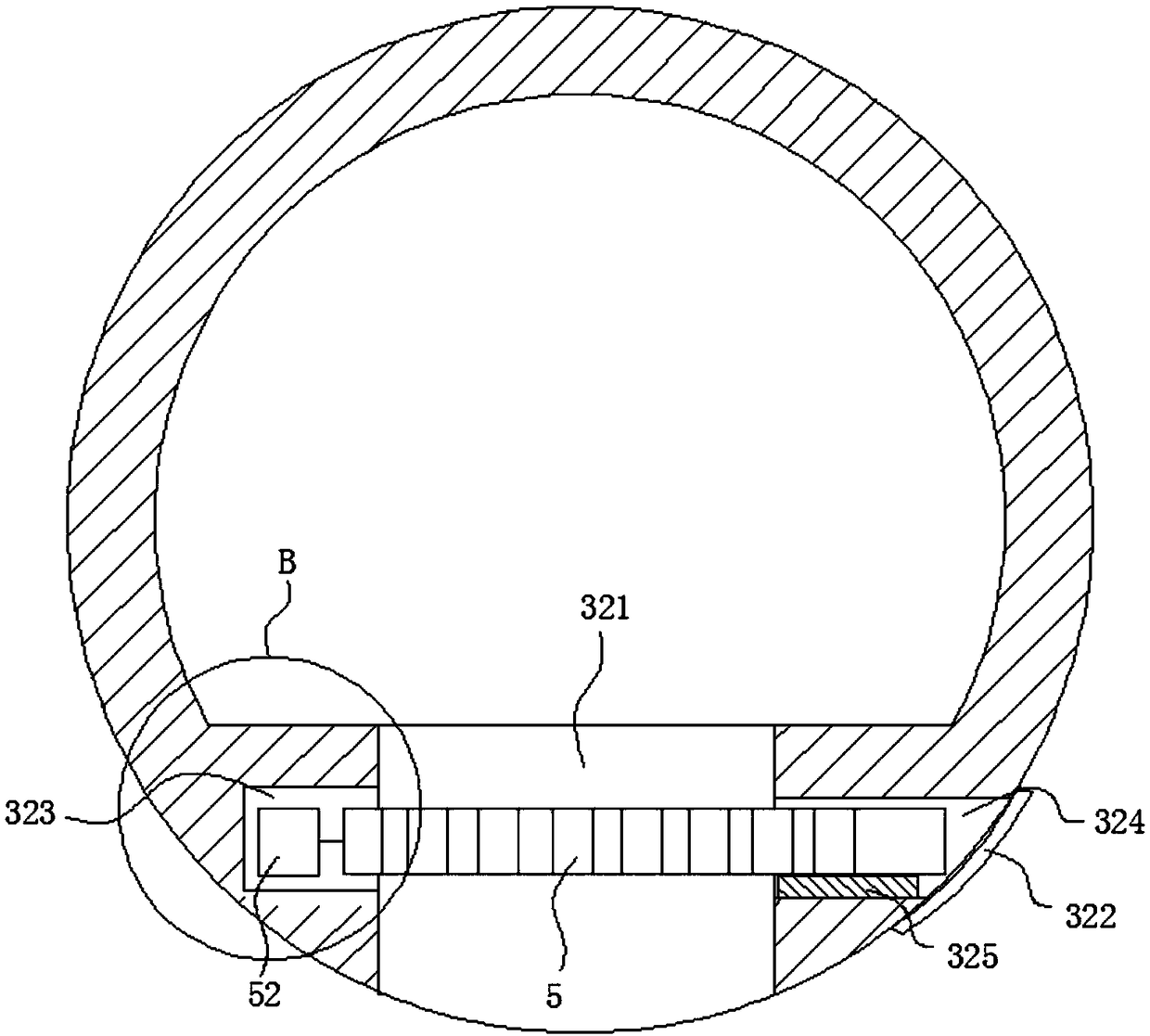

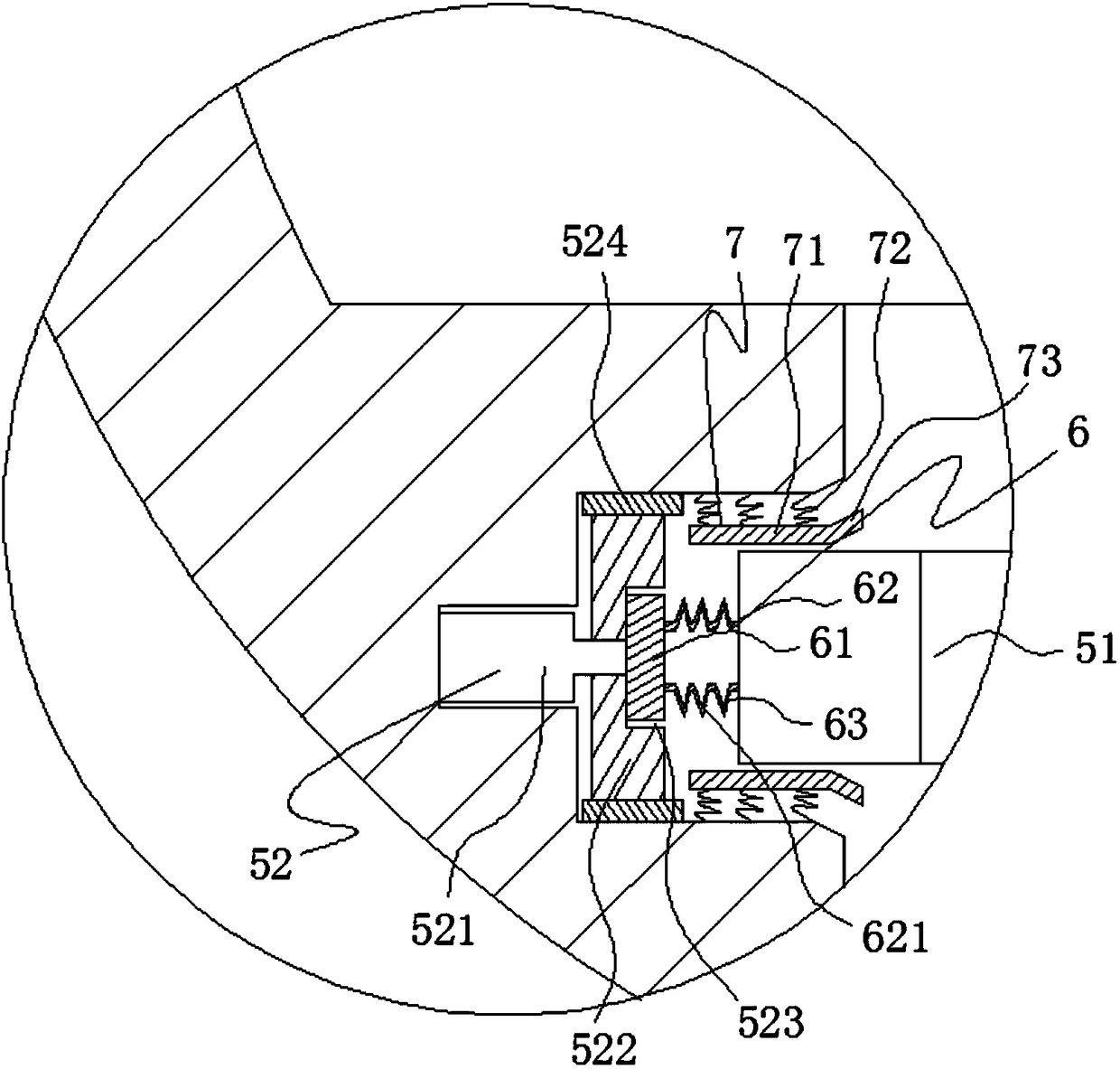

Method used

Image

Examples

Embodiment 1

[0035]A preparation method for high-strength concrete, comprising the following steps: (1) raw material preparation: take 500kg of cement, 1000kg of gravel, 160kg of water, 6kg of water reducing agent, 8kg of phenolic fiber and 60kg of montmorillonite; wherein the gravel passes through a crushing device Obtained by crushing construction waste, and the particle size of the sand is 8mm; the water reducer is composed of the following components in parts by weight: 40 parts of polycarboxylic acid mother liquor, 6 parts of slump-retaining agent, 2.5 parts of borax, 4 parts of plastic-preserving agent and 35 parts of water; the slump-preserving agent and plastic-preserving agent can be purchased directly on the market, so the materials are not specifically limited; (2) dry mixing: mix cement, gravel, water reducing agent, The phenolic fiber and montmorillonite are put into the mixer for dry material premixing, and the mixture A is obtained after mixing evenly; the specific mixing ste...

Embodiment 2

[0041] A preparation method for high-strength concrete, comprising the following steps: (1) raw material preparation: take 500kg of cement, 1000kg of gravel, 160kg of water, 6kg of water reducing agent, 8kg of phenolic fiber and 60kg of montmorillonite; wherein the gravel passes through a crushing device Obtained by crushing construction waste, and the particle size of the sand is 10mm; the water reducer is composed of the following components in parts by weight: 45 parts of polycarboxylic acid mother liquor, 10 parts of slump-retaining agent, 3.5 parts of borax, 6 parts of plastic-preserving agent and 40 parts of water; said slump-preserving agent and plastic-preserving agent can be purchased directly on the market, so the materials are not specifically limited; (2) dry mixing: mix cement, gravel, water reducing agent, The phenolic fiber and montmorillonite are put into the mixer for dry material premixing, and the mixture A is obtained after mixing evenly; the specific mixing...

Embodiment 3

[0044] A preparation method for high-strength concrete, comprising the following steps: (1) raw material preparation: take 500kg of cement, 1000kg of gravel, 160kg of water, 6kg of water reducing agent, 8kg of phenolic fiber and 60kg of montmorillonite; wherein the gravel passes through a crushing device Obtained by crushing construction waste, and the particle size of the sand is 8mm; the water reducer is composed of the following components in parts by weight: 45 parts of polycarboxylic acid mother liquor, 6 parts of slump-retaining agent, 2.5 parts of borax, 6 parts of plastic-preserving agent and 40 parts of water; the slump-preserving agent and plastic-preserving agent can be purchased directly on the market, so the materials are not specifically limited; (2) dry mixing: mix cement, gravel, water reducing agent, The phenolic fiber and montmorillonite are put into the mixer for dry material premixing, and the mixture A is obtained after mixing evenly; the specific mixing st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com