Pin removal device for semi-trailer tractor and use method of device

A tractor and tractor pin technology, applied in traction connectors, vehicle parts, transportation and packaging, etc., can solve the problem of not being suitable for semi-trailer tractors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

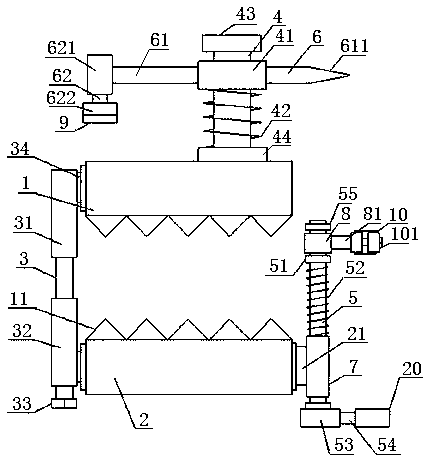

[0047] see figure 1 , a pin-out device for a semi-trailer tractor, including a car state clamping upper part 1 and a car state clamping lower part 2 with the same structure, a telescopic fixed rod 3, a No. 1 sliding rod 4, a No. 2 sliding rod 5, and a No. 1 screw rod 6. No. 1 sliding cylinder 7, the bottom surface of the clamping upper part 1 of the car state, and the top surface of the lower part 2 of the clamping state of the car state are provided with sawtooth 11, and the telescopic fixing rod 3 includes an upper fixing cylinder 31, a lower fixing cylinder 32. No. 2 screw 33, the No. 2 screw 33 passes through the lower fixing barrel 32 and is threadedly connected with the inner wall of the upper fixing barrel 31, and the side walls of the upper fixing barrel 31 and the lower fixing barrel 32 pass through the No. 1 connecting rod 34 are respectively welded with one end of the clamping upper part 1 of the car state and the lower part 2 of the clamping state of the car state,...

Embodiment 2

[0052] Structure is the same as embodiment 1, and difference is:

[0053] In the second step, the top of the traction pin is a plane structure, the user first slides down and rotates the sleeve 41 horizontally, so that the magnet 9 is attracted to the top of the traction pin to fix the top of the traction pin, and then steps on the pedal 20. Make the snap ring 10 collide with the positioning screw located at the tip of the traction pin until the positioning screw changes from a horizontal state to a vertical state. At this time, the No. 1 coil spring 42 pushes the sleeve 41 to slide upward under the action of its elastic force, vertically The rod 621 drives the traction pin to move upwards to realize depinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com