Battery pack heating control method

A heating control and battery pack technology, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of inaccurate temperature rise control, incomplete heating, and slow heating speed, and achieve fast heating speed, uniform heating, and control The effect of temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the objectives, technical solutions, and beneficial technical effects of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described in this specification are only for explaining the present invention, not for limiting the present invention.

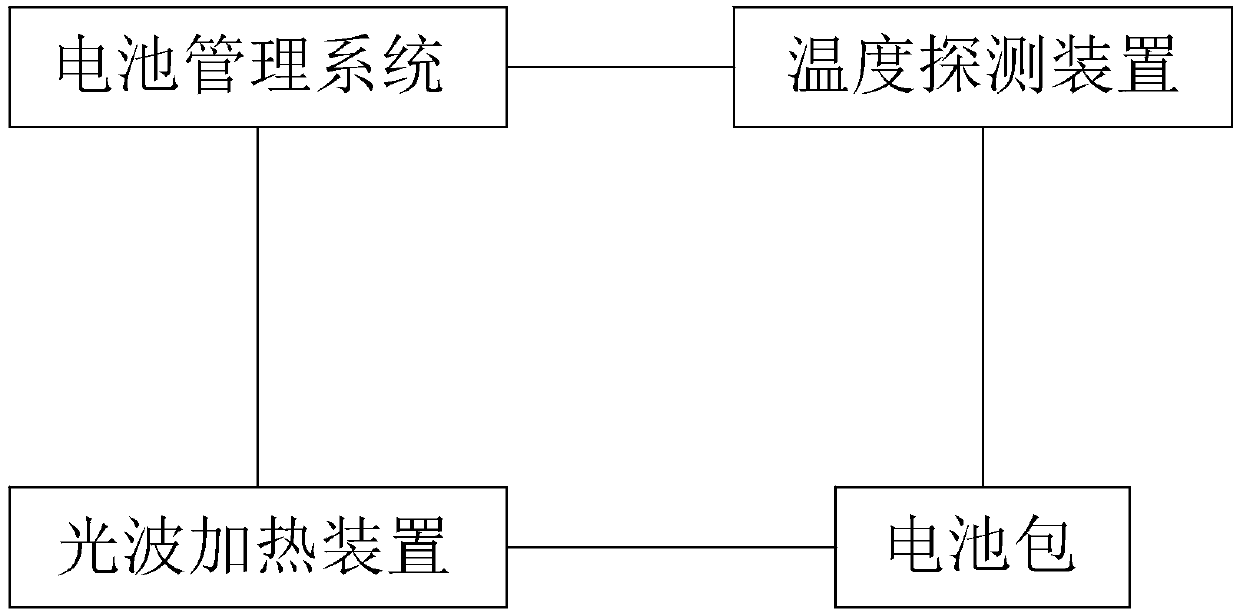

[0014] See figure 1 The present invention provides a battery pack heating control method, which uses a temperature detection device to detect the real-time temperature inside the battery pack and feeds the real-time temperature back to the battery management system. The battery management system obtains a real-time temperature lower than the first setting. Start the light wave heating device to heat the battery pack at a constant temperature. Compared with the heating belt in the prior art, the use of a light wave heating device to heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com