Reinforced lightning-protection insulation supporting column of annular valve plate structure

A technology of insulating pillar and sheet structure, which is applied to insulators, supporting insulators, electrical components, etc., can solve the problems of unfavorable lightning arrester lightning protection function, lack of load-bearing function, increasing supporting equipment and space occupation, etc., to achieve good protection. Lightning effect, improve overall insulation performance, reduce equipment installation and operation and maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

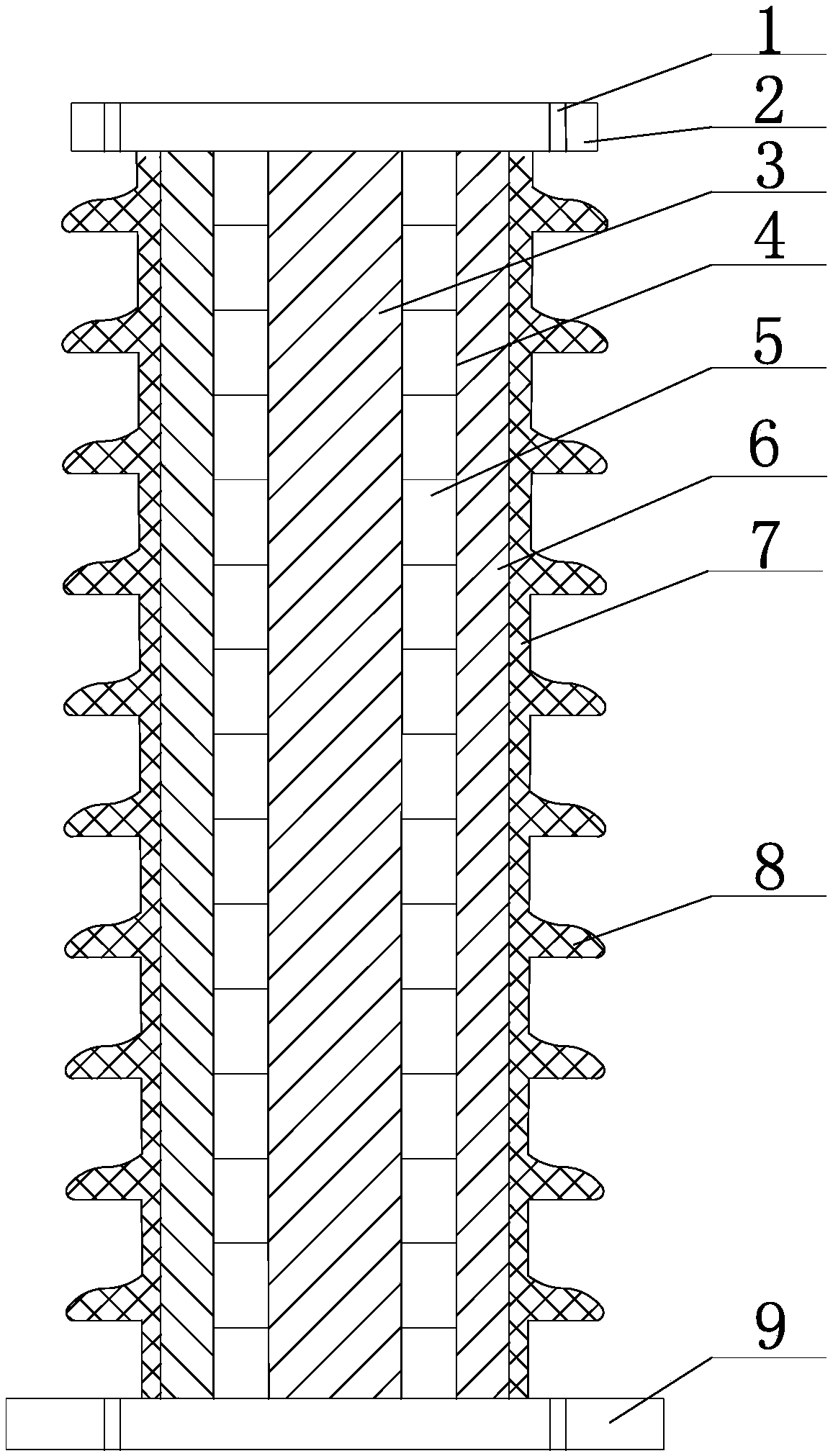

[0020] Such as figure 1 As shown, the reinforced lightning protection insulation pillar of the annular valve plate structure of the present invention includes an epoxy resin mandrel 3 and an insulating cylinder 6. The epoxy resin mandrel 3 is made of high-strength epoxy glass fiber and has good mechanical properties. It is an important load-bearing part of the insulating support, which can withstand the normal operating voltage and various overvoltages of the corresponding voltage level. The insulating cylinder 6 is set on the outside of the epoxy resin mandrel 3, and the upper end of the insulating cylinder 6 is provided with an upper The fixed flange 2, the lower end of the insulating cylinder 6 is provided with the lower fixed flange 9, the epoxy resin mandrel 3 and the insulating cylinder 6 are provided with an annular metal oxide valve plate group 4, the epoxy resin mandrel 3, the annular metal oxide The valve plate group 4 and the insulating cylinder 6 are set sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com