Two-way quick hydraulic cylinder

A hydraulic cylinder, fast technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of inaccurate extension length, fast extension speed, etc., and achieve the effect of increasing the shrinkage rate, reducing the stretching speed, and accelerating the return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

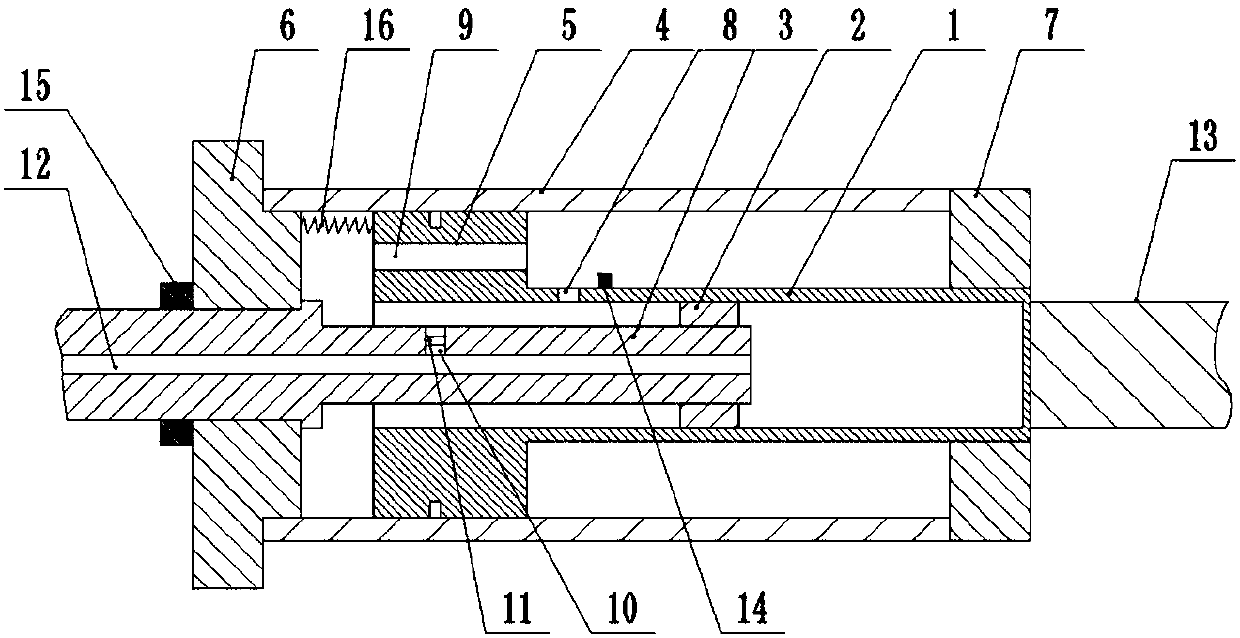

[0022] Such as figure 1 As shown, the two-way fast hydraulic cylinder includes a cylinder 1, a piston 2 and a piston rod 3 are connected inside the cylinder 1, a sealing disc 5 is connected to the left end of the cylinder 1, an oil outlet 8 is provided at the left end of the cylinder 1, and the sealing disc 5 There is an oil guide hole 9 on the top, a sleeve 4 is installed outside the sealing disc 5, the sealing disc 5 and the sleeve 4 are slidably and sealed connected, the right end of the cylinder 1 is connected with a push rod 13, the left end of the sleeve 4 is installed with a chassis 6, and the right end A fixed ring 7 is installed, the chassis 6 is fixedly connected with the piston rod 3, the piston rod 3 is provided with an oil inlet pipe 12 penetrating in the axial direction, the left end of the piston rod 3 is provided with an oil return hole 10, and a single To the valve 11, the left end of the cylinder barrel 1 is slidably and sealedly connected with the compressio...

Embodiment 2

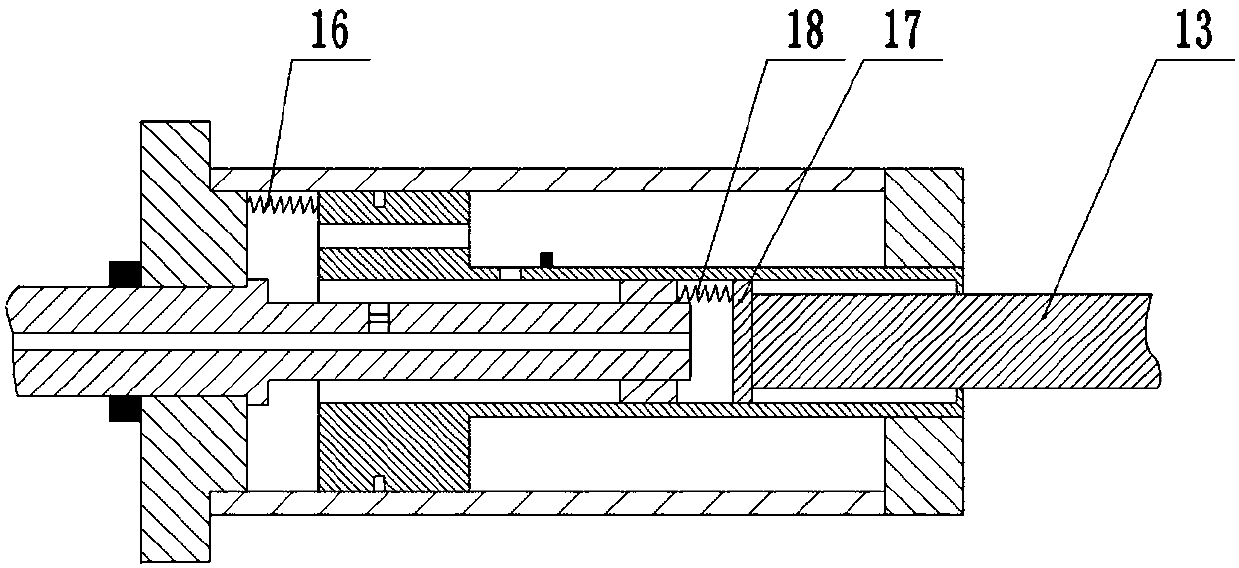

[0026] Such as figure 2 As shown, on the basis of the embodiment, a push plate 17 is installed at the left end of the push rod 13, and the push plate 17 is in sliding and sealed connection with the cylinder 1, and a second elastic member is connected between the push plate 17 and the piston 2, The second elastic part is preferably the second spring 18, which is convenient for the push rod 13 to increase the pulling force on the push plate 17 by the second spring 18 when shrinking, so as to realize rapid shrinkage; on the piston rod 3, a plurality of oil return valves evenly distributed in the axial direction are provided. A check valve 11 is installed in the hole 10 and the oil return hole 10, so as to facilitate the shrinkage of the cylinder barrel 1 and the push rod 13 to achieve a better rapid shrinkage effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com