A method for promoting yeast cell wall breaking

A yeast cell and yeast milk technology, applied in the field of promoting yeast cell wall breaking, can solve problems such as high operating costs, long working hours, and polluting the environment, and achieve the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

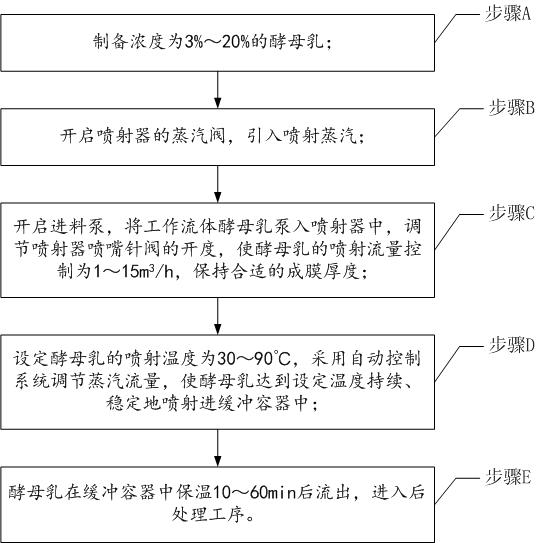

[0043] The method for promoting yeast cell wall breaking includes:

[0044] Prepare yeast milk with a concentration of 10%, open the steam valve of the injector, introduce jet steam, and turn on the feed pump to pump the yeast milk into the injector, adjust the opening of the injector nozzle needle valve, so that the injection of yeast milk Flow control is 3m 3 / h, to maintain an appropriate film thickness, so that the yeast milk can fully contact and exchange heat with the steam; set the injection temperature of the yeast milk to 70°C, adjust the steam flow through the automatic control system, and maintain the temperature of the yeast milk to keep stable, so that Yeast milk reaches the set temperature and is continuously and stably sprayed into the 0.5m 3 in the maintenance tank, and then flow into the 1.5 m 3 In the flash tank, keep warm for 40 minutes, flow out of the flash tank, and enter the post-treatment (enzymatic hydrolysis) process.

Embodiment 2

[0046] The method for promoting yeast cell wall breaking includes:

[0047] Prepare yeast milk with a concentration of 12%, open the steam valve of the injector, introduce jet steam, and turn on the feed pump to pump the yeast milk into the injector, adjust the opening of the injector nozzle needle valve, so that the injection of yeast milk Flow control is 12m 3 / h, to maintain an appropriate film thickness, so that the yeast milk can fully contact and exchange heat with the steam; set the injection temperature of the yeast milk to 90°C, adjust the steam flow through the automatic control system, and maintain the temperature of the yeast milk to keep stable, so that Yeast milk reaches the set temperature and is continuously and stably sprayed into the 0.5m 3 in the maintenance tank, and then flow into the 1.5 m 3 In the flash tank, keep warm for 10 minutes, flow out of the flash tank, and enter the post-treatment (enzymatic hydrolysis) process.

Embodiment 3

[0049] The method for promoting yeast cell wall breaking includes:

[0050] Prepare yeast milk with a concentration of 3%, open the steam valve of the injector, introduce jet steam, and turn on the feed pump to pump the yeast milk into the injector, adjust the opening of the needle valve of the injector nozzle, so that the injection of yeast milk Flow control is 1m 3 / h, to maintain an appropriate film thickness so that the yeast milk can fully contact and exchange heat with the steam; set the injection temperature of the yeast milk to 50°C, adjust the steam flow through the automatic control system, and maintain the temperature of the yeast milk to keep stable, so that Yeast milk reaches the set temperature and is continuously and stably sprayed into the 0.5m 3 in the maintenance tank, and then flow into the 1.5 m 3 In the flash tank, keep warm for 25 minutes, flow out of the flash tank, and enter the post-treatment (enzymatic hydrolysis) process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com