Ultrahigh-temperature-resistant lubricating oil and synthesis method thereof

A lubricating oil and ultra-high temperature technology, applied in the field of lubricating oil, can solve problems affecting the stability of lubricants, long running time, viscosity changes, etc., and achieve excellent lubricating effect, good lubricating durability, and enhanced compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

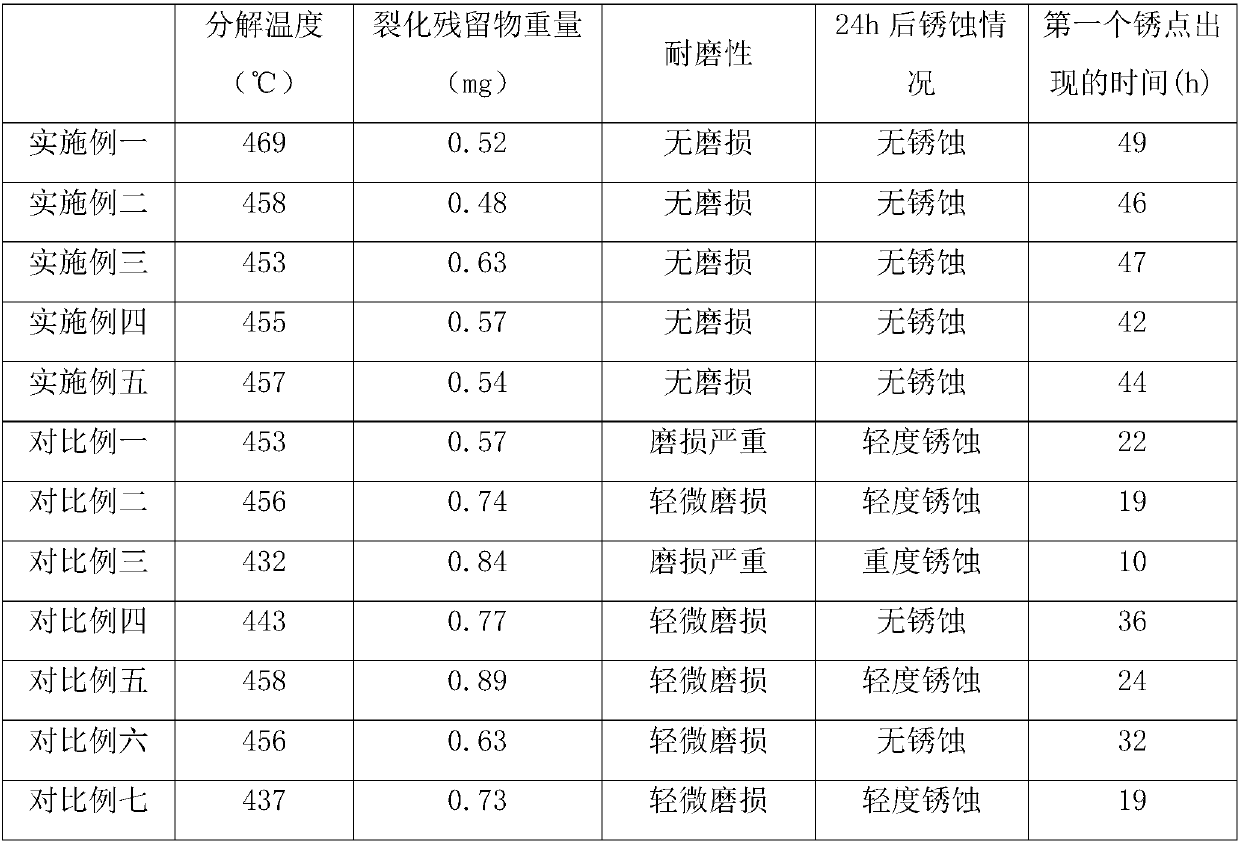

Examples

preparation example Construction

[0046] Two of the object of the present invention is to provide a kind of synthetic method according to above-mentioned ultra-high temperature resistant lubricating oil, comprise the steps:

[0047] Step 1: Disperse graphene in a solvent, stir and disperse evenly, add modifier, heat and stir at 60°C for 1-4 hours, filter with suction or press, and dry to obtain modified graphene.

[0048] Step 2: Put the modified graphene, base oil, inorganic thickening, and additives into the lubricating oil production equipment according to the weight ratio, and adjust the speed by frequency conversion to make the stirring blade fully stir and mix the materials at a suitable speed, and mix the materials ,Discharge.

[0049] Step 3: Put the materials obtained in Step 2 into a defoaming machine, vacuum degassing and dehydrating, and pack in cans to obtain the required overtemperature-resistant lubricating oil.

[0050] As a preferred embodiment, the solvent is a common solvent, such as deioni...

Embodiment 1

[0056] The synthetic method of lubricant in the present embodiment, comprises the steps:

[0057] Step 1: Disperse graphene in a solvent, stir and disperse evenly, add POSS with good solubility, heat and stir at 60°C for 2 hours, press filter, and dry to obtain modified graphene.

[0058] Step 2: put 5 parts by weight of modified graphene, 130 parts by weight of dimethyl diphenyl silicone oil, 10 parts by weight of bentonite, and 5 parts by weight of additives into the high-speed shear emulsification stirring equipment, and adjust the speed of the stirring paddle by frequency conversion. The leaves fully stir and mix the materials at an appropriate speed, mix and discharge; the additives are one or more mixtures of antioxidants, anti-wear additives, stabilizers, corrosion inhibitors or defoamers.

[0059] Step 3: Put the material obtained in Step 2 into a degassing machine, vacuum defoam and dehydrate it, and pack it in a can to obtain the required lubricating oil.

Embodiment 2

[0061] The synthetic method of lubricant in the present embodiment, comprises the steps:

[0062] Step 1: Disperse graphene in a solvent, stir and disperse evenly, add POSS with good solubility, heat and stir at 60°C for 1 hour, press filter, and dry to obtain modified graphene.

[0063] Step 2: put 15 parts by weight of modified graphene, 120 parts by weight of dimethyl diphenyl silicone oil, 2 parts by weight of silica gel thickener, and 0.1 parts by weight of additives into a vacuum high-speed mixer, and adjust the speed by frequency conversion to make the stirring blade The leaves fully stir and mix the materials at an appropriate speed, mix and discharge; the additives are one or more mixtures of antioxidants, anti-wear additives, stabilizers, corrosion inhibitors or defoamers.

[0064] Step 3: Put the material obtained in Step 2 into a degassing machine, vacuum defoam and dehydrate it, and pack it in a can to obtain the required lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com