Weathering resistance enhancing coating varnish and preparation method and application thereof

A varnish and weather-resistant technology, which is applied in coatings, reflective/signal coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult to improve the weather resistance of coatings supporting coatings, achieve the best decorative effect, good construction performance, The effect of high solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Ratio of main raw materials: main agent: curing agent = 100 parts: 30 parts.

[0079] in:

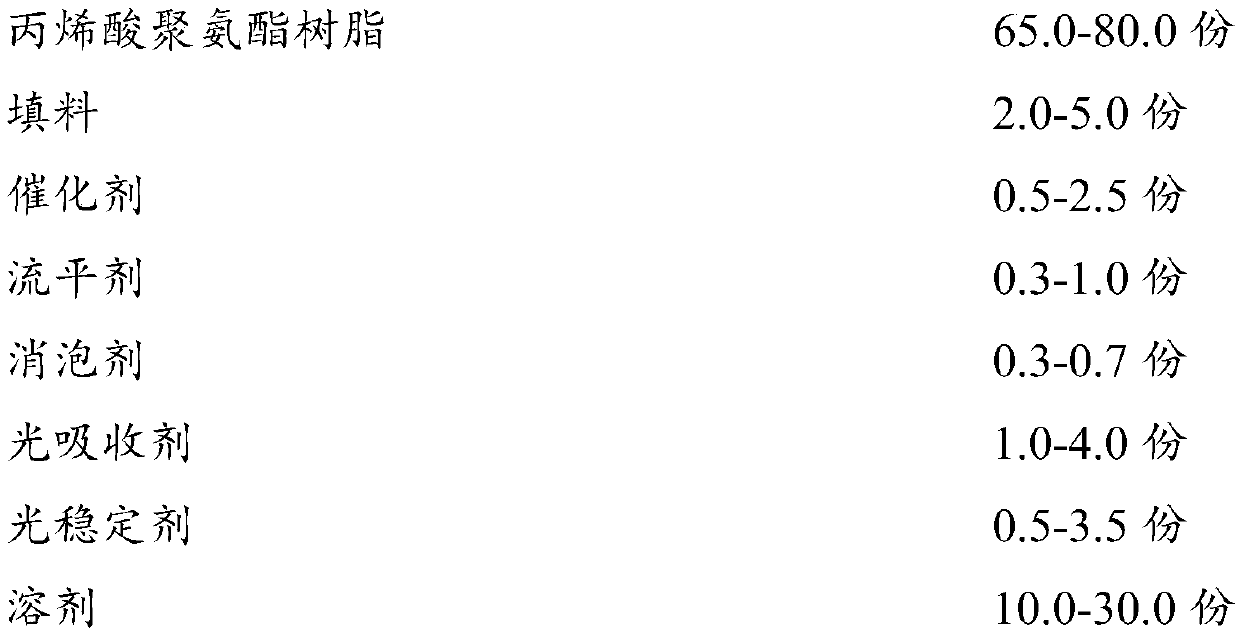

[0080] Main agent:

[0081]

[0082]

[0083] Wherein the main agent solvent ratio is:

[0084] Butyl propionate 16.0 parts

[0085] Heavy aromatics 5.0 parts

[0086] Ethylene glycol butyl ether acetate 2.0 parts

[0087] hardener:

[0088] Polyisocyanate 21.5 parts

[0089] Water absorbent 1.0 parts

[0090] Solvent 8.4 parts

[0091] Wherein the solvent ratio in the hardener is:

[0092] Butyl propionate 6.8 parts

[0093] Heavy aromatics 1.0 parts

Embodiment 2

[0096] Ratio of main raw materials: main agent: curing agent = 100 parts: 50 parts.

[0097] in:

[0098] Main agent:

[0099]

[0100] Wherein the main agent solvent ratio is:

[0101] Butyl propionate 9.2 parts

[0102] 1.7 parts of heavy aromatics

[0103] Ethylene glycol butyl ether acetate 2.1 parts

[0104] hardener:

[0105] 31.5 parts of polyisocyanate

[0106] 1.5 parts of water absorbent

[0107] Solvent 18.35 parts

[0108] Wherein the solvent ratio in the hardener is:

[0109] Butyl propionate 16.6 parts

[0110] 1.7 parts of heavy aromatics

[0111] Ethylene glycol butyl ether acetate 0.05 parts.

Embodiment 3

[0113] Ratio of main raw materials: main agent: curing agent = 100 parts: 40 parts

[0114] Main ingredient:

[0115]

[0116] Wherein the main agent solvent ratio is:

[0117] Butyl propionate 14.0 parts

[0118] 2.5 parts of heavy aromatics

[0119] Ethylene glycol butyl ether acetate 1.4 parts

[0120] hardener:

[0121] Polyisocyanate 27.5 parts

[0122] Water absorbent 1.2 parts

[0123] Solvent 12.38 parts

[0124] Wherein the solvent ratio in the hardener is:

[0125] Butyl propionate 10.8 parts

[0126] Heavy aromatics 1.0 parts

[0127] Ethylene glycol butyl ether acetate 0.58 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com