PVC (polyvinyl chloride) floor based on wood-plastic structure and preparation method of PVC floor

A flooring and wood-plastic technology, which is applied in the field of PVC flooring based on wood-plastic structure and its preparation, can solve the problems of high cost, insufficiently high-grade PVC material, cracking, etc., and achieve the effect of prolonging service life and improving thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

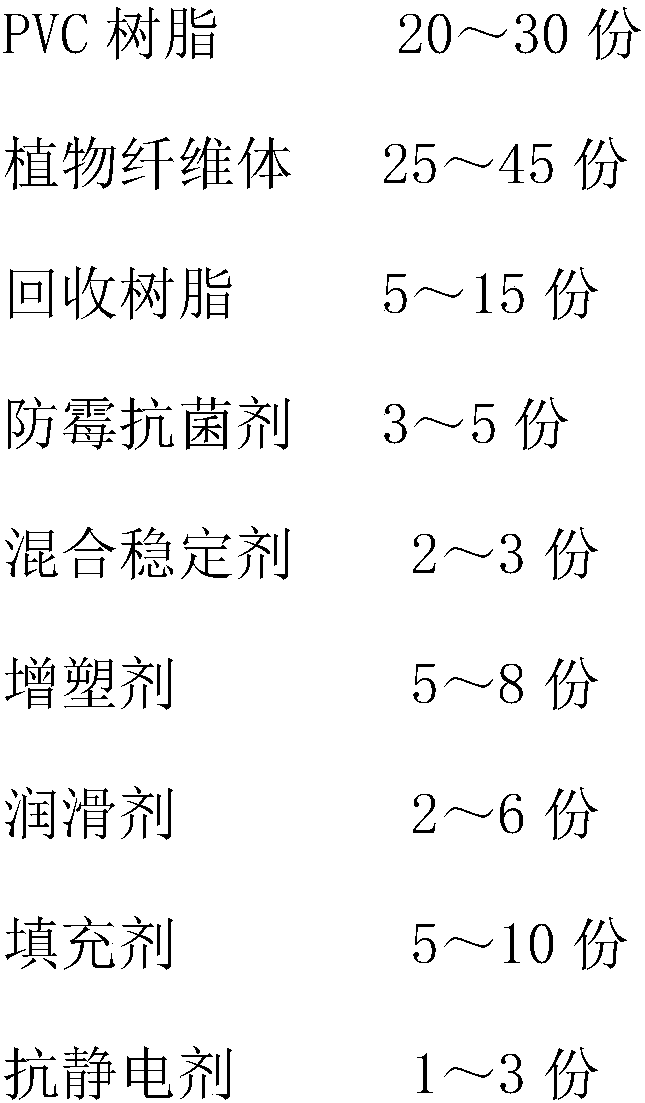

Embodiment 1

[0026] A PVC floor based on wood-plastic structure includes 20-30 parts of PVC resin, 35 parts of plant fiber body, 10 parts of recycled resin, 4 parts of anti-mold and antibacterial agent, 3 parts of mixed stabilizer, 5 parts of plasticizer, and 3 parts of lubricant , 6 parts of filler, 2 parts of antistatic agent; The plant fiber body includes sawdust shavings, bamboo fiber, cotton shavings, banana stalks, coconut shells, and nut shells in a ratio of 2:1:1:1:1:0.5 The particle size of the fiber is between 45 meshes; the recycled resin includes: recycled resin and polyolefin thermoplastic elastomer, and the recycled resin is obtained after crushing recycled scraps of PVC, and recycled resin and polyolefin thermoplastic elastomer The mixed stabilizer is formed by mixing a calcium zinc stabilizer and p-nitrophenyl salicylate in a ratio of 2:1.

[0027] The plasticizer is formed by compounding DOP and epoxidized soybean oil in a ratio of 3:1. The lubricant is compounded from ox...

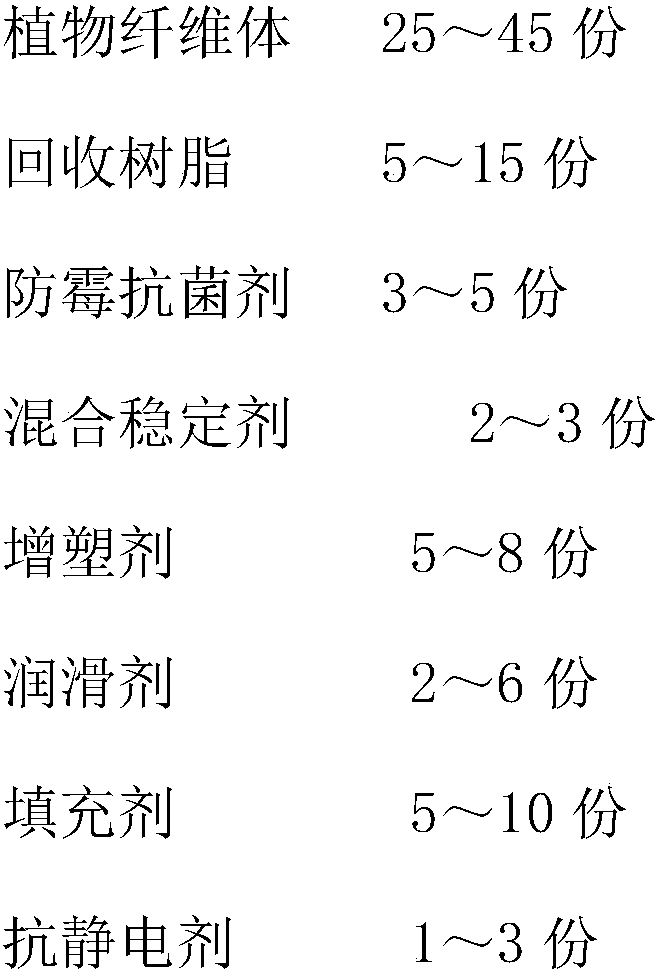

Embodiment 2

[0030] A PVC floor based on wood-plastic structure includes 20-30 parts of PVC resin, 45 parts of plant fiber body, 15 parts of recycled resin, 5 parts of anti-mold and antibacterial agent, 3 parts of mixed stabilizer, 8 parts of plasticizer, and 5 parts of lubricant , 8 parts of filler, 2 parts of antistatic agent; The plant fiber body includes sawdust shavings, bamboo fiber, cotton shavings, banana stalks, coconut shells, and nut shells in a ratio of 2:1:1:1:1:0.5 The particle size of the fiber is 60 mesh; the recycled resin includes: recycled resin and polyolefin thermoplastic elastomer, and the recycled resin is obtained after crushing recycled scraps of PVC, and the recycled resin and polyolefin thermoplastic elastomer are obtained in the form of It is formed by mixing with a ratio of 5:1; the mixed stabilizer includes calcium zinc stabilizer and p-nitrophenyl salicylate in a ratio of 2:1.

[0031] The plasticizer is formed by compounding DOP and epoxidized soybean oil in...

Embodiment 3

[0034] A PVC floor based on wood-plastic structure includes 30 parts of PVC resin, 25 parts of plant fiber body, 10 parts of recycled resin, 3 parts of anti-mold and antibacterial agent, 3 parts of mixed stabilizer, 8 parts of plasticizer, 6 parts of lubricant, - 5 parts of filler, 1 part of antistatic agent; the plant fiber body includes sawdust shavings, bamboo fiber, cotton shavings, banana stalks, coconut shells, and nut shells in a ratio of 2:1:1:1:1:0.5 Adding, the particle diameter of fiber is at 60 orders; The reclaimed resin comprises: reclaimed resin and polyolefin thermoplastic elastomer, and described reclaimed resin is that PVC reclaims leftover material to obtain after crushing, and reclaimed resin and polyolefin thermoplastic elastomer with 5 It is formed by mixing in a ratio of 1; the mixed stabilizer comprises a calcium zinc stabilizer and p-nitrophenyl salicylate in a ratio of 2:1.

[0035] The plasticizer is formed by compounding DOP and epoxidized soybean o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com