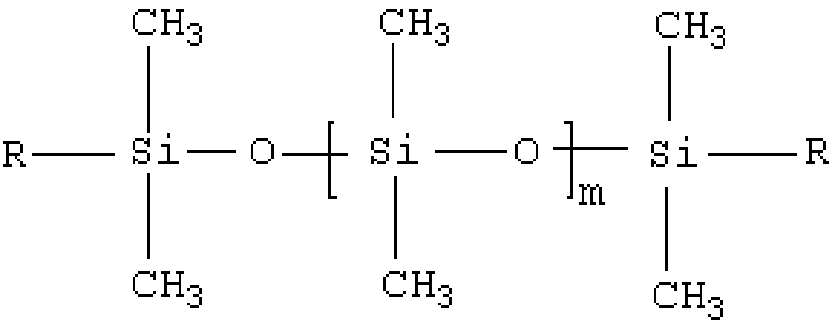

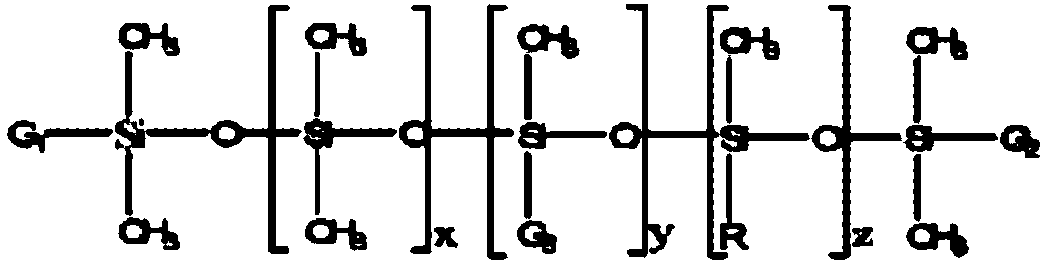

Ultra-high-molecular-weight polyether modified polysiloxane for flatting agent and preparation method and application of polyether modified polysiloxane

An ultra-high molecular weight, polyether modified technology, which is applied in applications, household appliances, coatings, etc., can solve the problems of leveling, scratch resistance and gloss, reduce leveling, and difficulty in synthesis, etc., to achieve Excellent leveling and anti-scratch performance, reduce steric hindrance effect, improve gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of ultra-high molecular weight polyether modified polysiloxane, comprising steps:

[0055] (1) Allyl polyether (the molar ratio of ring ethoxy and cyclopropoxy is 1:1, the molecular weight is 500g / mol, hydroxyl end-blocking, available from Hangzhou Danwei Technology Co., Ltd.) and toluene into a three-necked flask And add a condensing reflux device, add a tetrahydrofuran solution of chloroplatinic acid with a mass concentration of 2%, and heat up to 80°C, which is conducive to the rapid completion of the hydrosilylation reaction at a higher temperature, and slowly add methyldichlorosilane dropwise to allow Methyldichlorosilane fully reacted to reduce losses, and the dropwise addition time was 1 hour. React at 90°C for 6 hours; then distill under reduced pressure at 110°C for 1 hour to obtain silicon ether; among them, the mass of toluene is 30% of the total mass of allyl polyether and methyl dichlorosilane; The molar ratio of propyl polyether is 1....

Embodiment 2

[0061] A preparation method of ultra-high molecular weight polyether modified polysiloxane, comprising steps:

[0062] (1) Allyl polyether (the molar ratio of ring ethoxy group and cyclopropoxy group in the raw material is 3:1, the molecular weight is 1000g / mol, hydroxyl end-capping, Zhejiang Huangma Technology Co., Ltd. DEM-1002) and toluene are added to the three-necked flask And add a condensing reflux device, add a tetrahydrofuran solution of chloroplatinic acid with a mass concentration of 2%, heat up to 82°C, slowly add methyldichlorosilane dropwise, the dropwise addition time is 1 hour, and react at 100°C for 6 hours; then Distill under reduced pressure at 110°C for 1 hour to obtain silicon ether; among them, the mass of toluene is 35% of the total mass of allyl polyether and methyl dichlorosilane; the molar ratio of methyl dichlorosilane to allyl polyether is 1.2 : 1; In terms of pure substance, the quality of chloroplatinic acid used is 0.0025% of the total mass of al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com