Preparation method of superfine calcined kaolin powder

A technology of kaolin and activated kaolin, which is applied in the field of preparation of calcined kaolin superfine powder, can solve problems such as poor resistance to sulfate erosion, affecting material properties, and slightly poor dry shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Select the chemical composition of kaolin as: Al 2 o 3 =37.22%, SiO 2 =46.58%, Fe 2 o 3 =0.63%, TiO 2 =0.46%, CaO=0.14%, MgO=0.06%, K 2 O=0.26%, Na 2 O=0.09%, Loss=14.46%. The kaolin fine-grained ore is dried and ground to <0.088mm, and then sent to a fluidized device for calcination at 900°C×30s. The calculation formula for the calcination time is "calcination time = length of the fluidized calcination device / average flow rate of the device", The calcined materials are processed to ≤0.044mm calcined kaolin superfine powder and ≤0.010mm fine powder, which are used to configure clay bricks for glass kiln tin baths. The ratio is: 51.5% of 8-1mm burnt gemstone, 19.8% of <1mm burnt gemstone, 10.1% of <0.088mm burnt gemstone, 4.6% of <0.088mm kaolin-based mullite, 4.4% of <0.044mm kaolin fine powder, <0.010mm Kaolin micropowder 4.6%, silica fume 2%, pure calcium aluminate cement 3%.

[0014] After adding water and molding, the 1-day flexural strength is 3.5MPa, whic...

Embodiment 2

[0016] Select the chemical composition of kaolin as: Al 2 o 3 =37.22%, SiO 2 =46.58%, Fe 2 o 3 =0.63%, TiO 2 =0.46%, CaO=0.14%, MgO=0.06%, K 2 O=0.26%, Na 2 O=0.09%, Loss=14.46%. The kaolin fine-grained ore is dried and ground to <0.088mm, and then sent to a fluidized device for calcination at 1100°C×20s. The calculation formula for the calcination time is "calcination time = length of the fluidized calcination device / average flow rate of the device", The calcined materials are processed to ≤0.044mm calcined kaolin superfine powder and ≤0.010mm fine powder, which are used to configure clay bricks for glass kiln tin baths. The ratio is: 51.5% of 8-1mm burnt gemstone, 19.8% of <1mm burnt gemstone, 10.1% of <0.088mm burnt gemstone, 4.6% of <0.088mm kaolin-based mullite, 4.4% of <0.044mm kaolin fine powder, <0.010mm Kaolin micropowder 4.6%, silica fume 2%, pure calcium aluminate cement 3%. After adding water and forming, the flexural strength of 1 day is 3.6MPa, which mee...

Embodiment 3

[0018] Select the chemical composition of kaolin as: Al 2 o 3 =37.22%, SiO 2 =46.58%, Fe 2 o 3 =0.63%, TiO 2 =0.46%, CaO=0.14%, MgO=0.06%, K 2 O=0.26%, Na 2 O=0.09%, Loss=14.46%. The kaolin fine-grained ore is dried and ground to <0.088mm, and then sent to a fluidized device for calcination at 1200°C×15s. The calculation formula for the calcination time is "calcination time = length of the fluidized calcination device / average flow rate of the device", The calcined materials are processed to ≤0.044mm calcined kaolin superfine powder and ≤0.010mm fine powder, which are used to configure clay bricks for glass kiln tin baths. The ratio is: 51.5% of 8-1mm burnt gemstone, 19.8% of <1mm burnt gemstone, 10.1% of <0.088mm burnt gemstone, 4.6% of <0.088mm kaolin-based mullite, 4.4% of <0.044mm kaolin fine powder, <0.010mm Kaolin micropowder 4.6%, silica fume 2%, pure calcium aluminate cement 3%. After forming with water, the flexural strength of 1 day is 3.65MPa, which meets th...

PUM

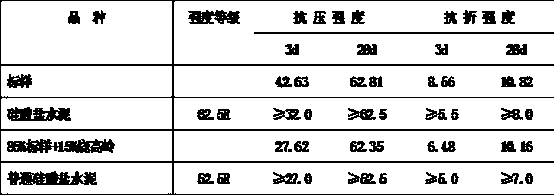

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com