Clarification tank used for treating wastewater in photovoltaic industry

A wastewater treatment and clarifier technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of slow reaction speed, low efficiency of wastewater treatment, and sludge backflow and other problems, to achieve the effect of thorough mixing, improvement of wastewater treatment efficiency, and rapid flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

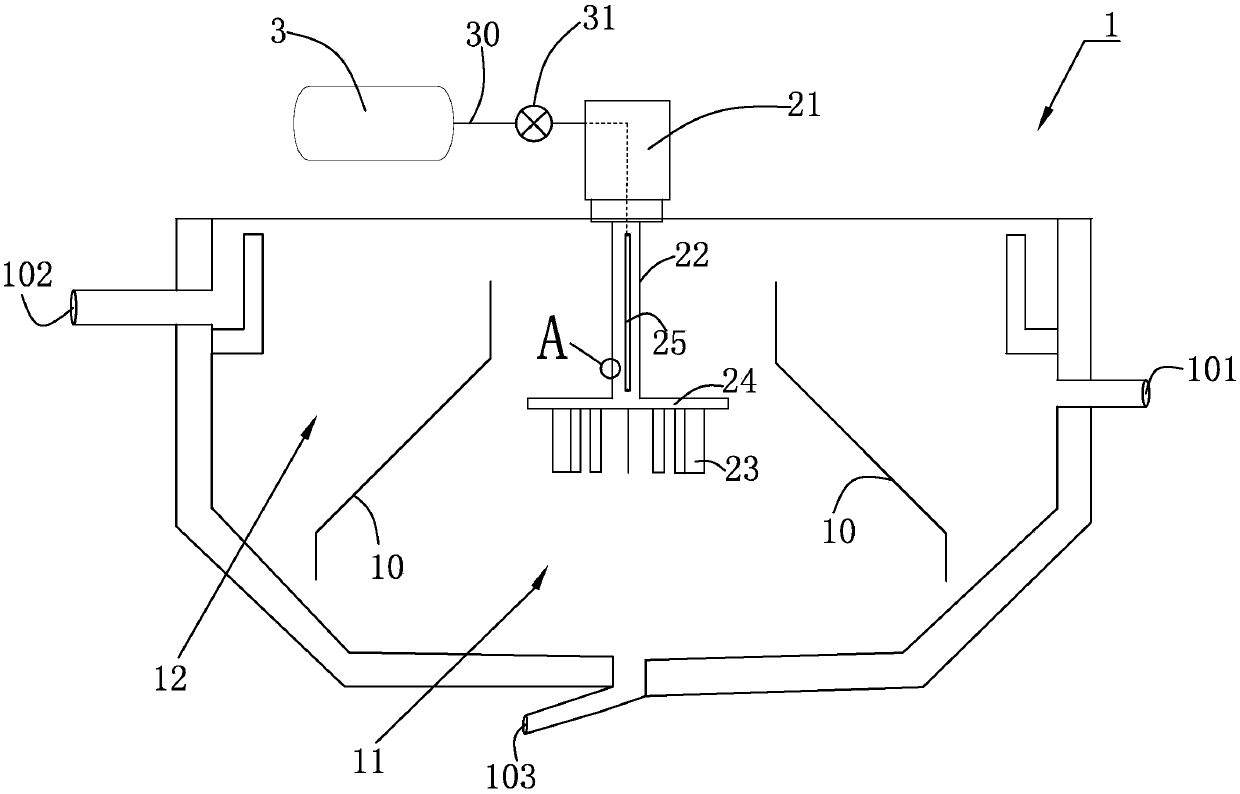

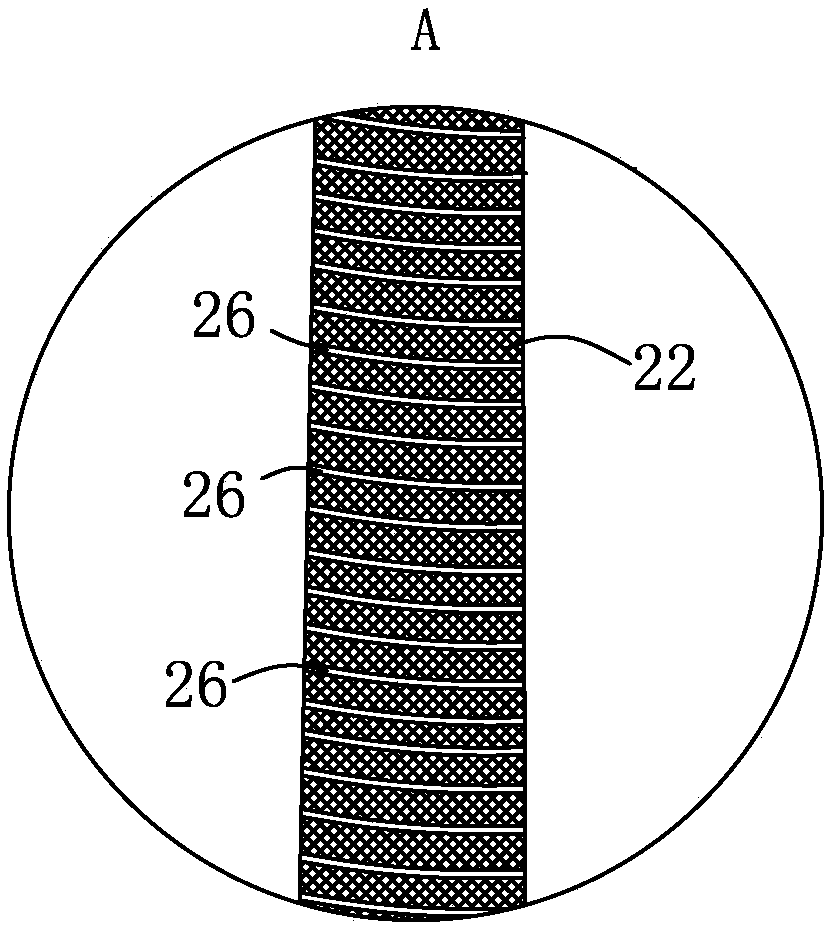

[0020] as attached figure 1 and figure 2 As shown, the present embodiment provides a clarification tank for wastewater treatment in the photovoltaic industry. The clarification tank includes a tank body 1 with a water inlet 101, a water outlet 102 and a sludge discharge port 103, and a stirring tank on the tank body 1. The mechanical agitation and lifting system for the wastewater in the pool body 1, and the drug supply system 3 for supplying chemicals to the wastewater in the pool body 1; a reaction chamber 11 and a separation chamber 12 that communicate with each other are formed inside the pool body 1, and the drug supply system 3 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com