A kind of preparation method of supercapacitor electrode material vanadium sulfide nanoflower

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low specific capacity and poor cycle life of vanadium sulfide, achieve high specific capacity, long cycle life, avoid stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

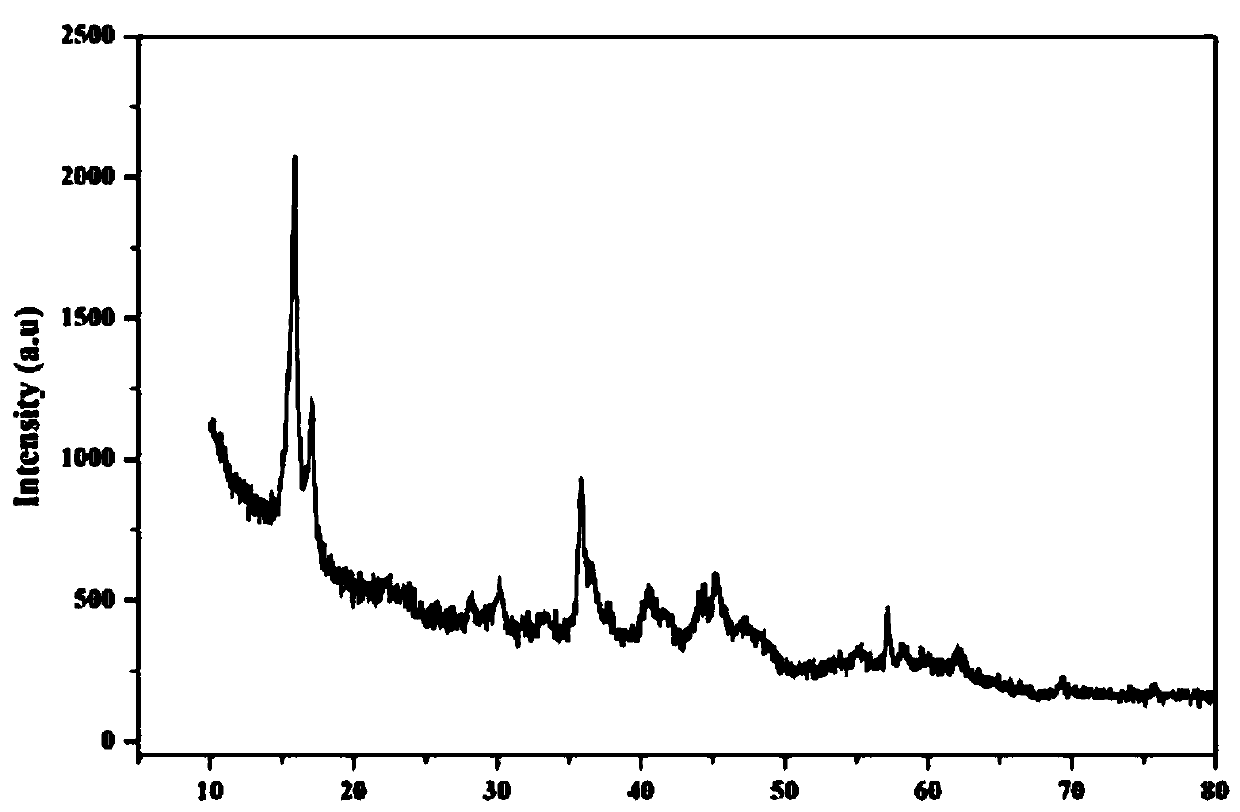

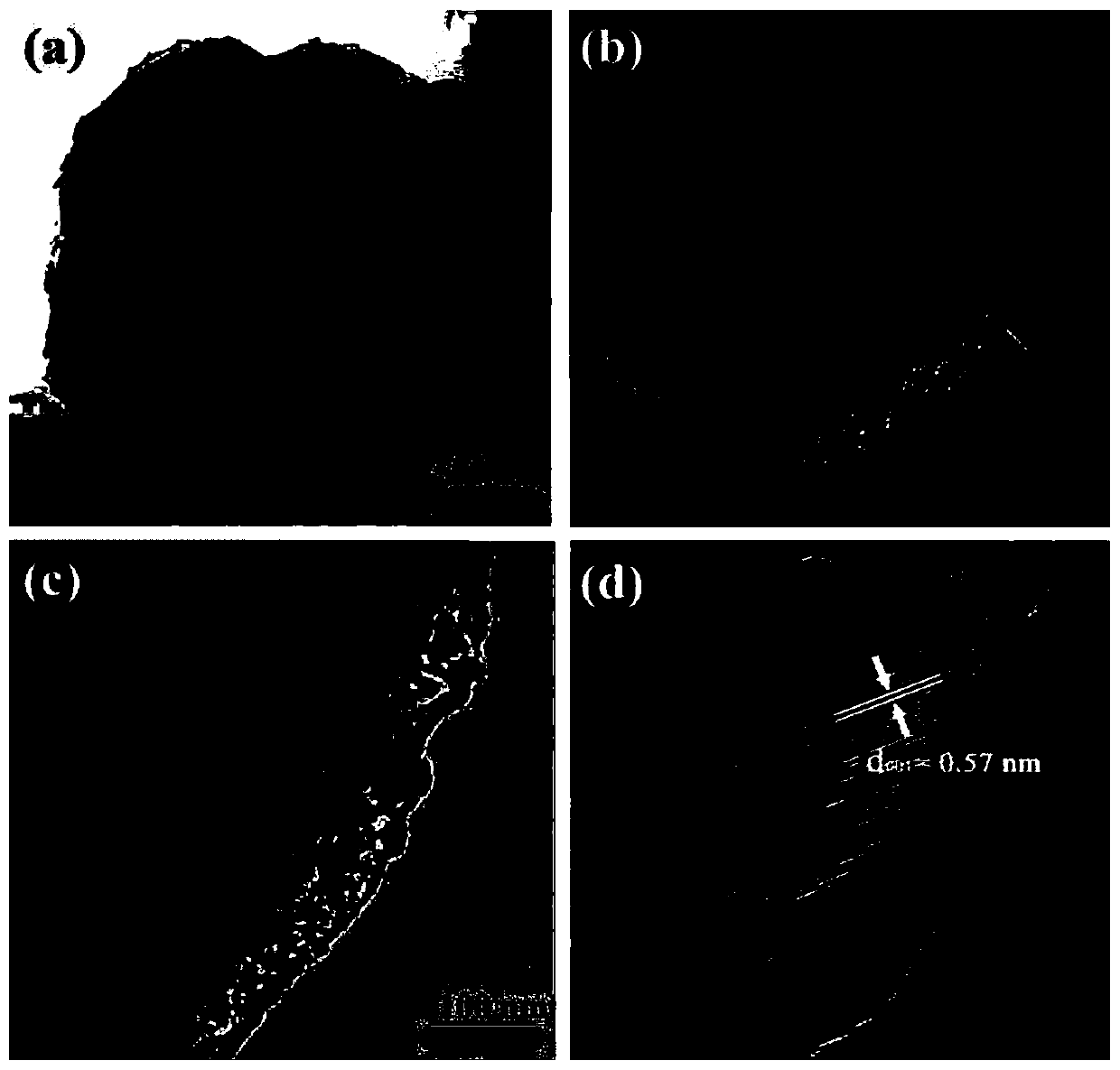

Image

Examples

Embodiment 1

[0037] The preparation method of the present embodiment vanadium sulfide nanoflowers comprises the following steps:

[0038] (1) Sodium orthovanadate dodecahydrate (Na 3 VO 4 12H 2 O, 0.9g) and thioacetamide (C 2 h 5 NS, 2.7g) was dissolved in 30mL of water (the concentration of sodium orthovanadate dodecahydrate was 0.03g / mL), and the resulting mixture was placed in a constant temperature water bath at 25°C and stirred for 60min to obtain a light yellow precursor solution;

[0039] (2) Transfer the obtained precursor solution into a 50mL reaction kettle lined with polytetrafluoroethylene, and place the reaction kettle in a blast drying oven at 140°C for hydrothermal reaction for 24 hours. After the reaction is completed, the reaction kettle is naturally After cooling, the obtained product was washed successively with deionized water and ethanol three times respectively, and then dried in a vacuum oven (-0.09MPa) at 80°C for 12 hours to obtain the nano-sized vanadium sulfi...

Embodiment 2

[0041] The preparation method of the present embodiment vanadium sulfide nanoflowers comprises the following steps:

[0042] (1) Sodium orthovanadate dodecahydrate (Na 3 VO 4 12H 2 O, 0.9g) and thioacetamide (C 2 h 5 NS, 1.8g) was dissolved in 30mL of water (the concentration of sodium orthovanadate dodecahydrate was 0.03g / mL), and the resulting mixture was placed in a constant temperature water bath at 25°C and stirred for 50min to obtain a light yellow precursor solution;

[0043] (2) Transfer the obtained precursor solution into a 50mL reaction kettle lined with polytetrafluoroethylene, and place the reaction kettle in a blast drying oven at 160°C for hydrothermal reaction for 22 hours. After the reaction is completed, put the reaction kettle naturally After cooling, the obtained product was washed successively with deionized water and ethanol three times respectively, and then dried in a vacuum oven (-0.09MPa) at 80°C for 12 hours to obtain the nano-sized vanadium sulfid...

Embodiment 3

[0045] The preparation method of vanadium sulfide nanoflowers in this example is the same as in Example 1, except that the mass ratio of sodium orthovanadate dodecahydrate and thioacetamide in this example is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com