Decorative fiberboard and its preparation method

A technology of fiberboard and wood fiber, which is applied in the field of decorative fiberboard and its preparation, and can solve the problems of heavy weight of the board, not suitable for practical application of light weight, and difficulty in handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

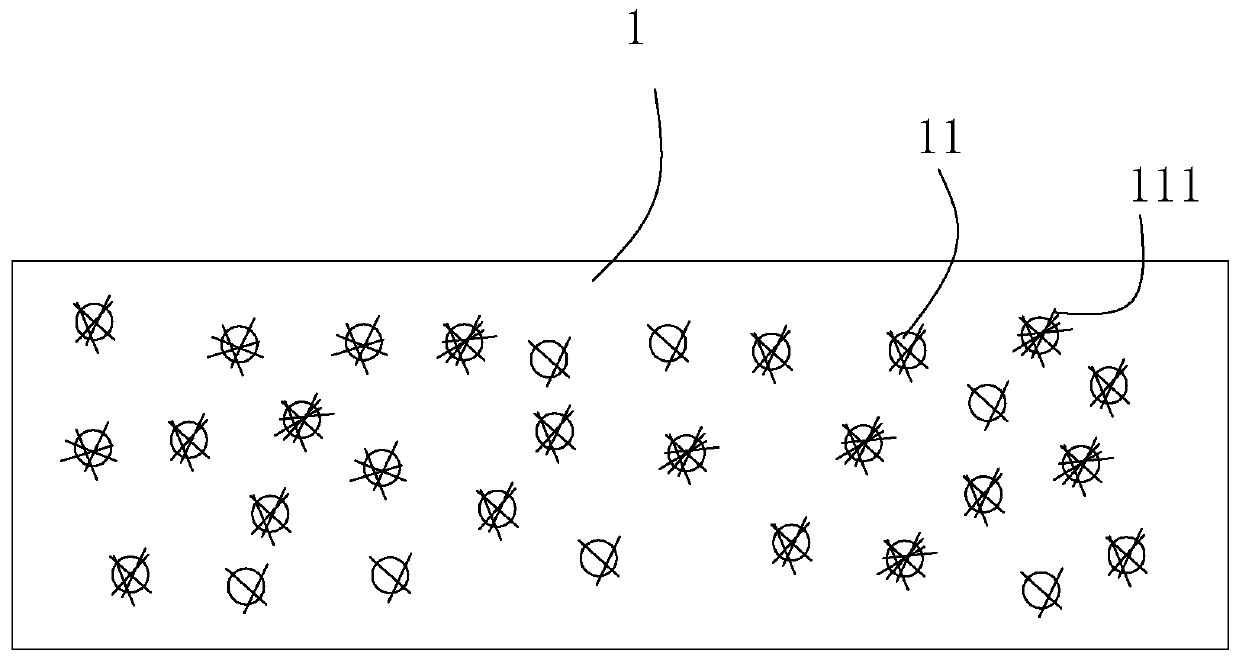

[0047] A kind of decorative fiberboard, refer to figure 1 as well as figure 2 , including a high-density plate body 1 pressed by wood fibers, the plate body 1 is flat, and a number of densely distributed microholes 11 are arranged in the plate body 1, and a number of short glass fibers 111 are connected to the microholes 11.

[0048] The microhole 11 is spherical, and the short glass fiber 111 runs through the microhole 11 randomly and both ends are connected with the wood fiber of the solid part near the microhole 11 , and the microhole 11 is reinforced by the short glass fiber 111 .

[0049] The surface of the board body 1 is coated with a waterproof coating (not shown in the figure).

preparation Embodiment 1

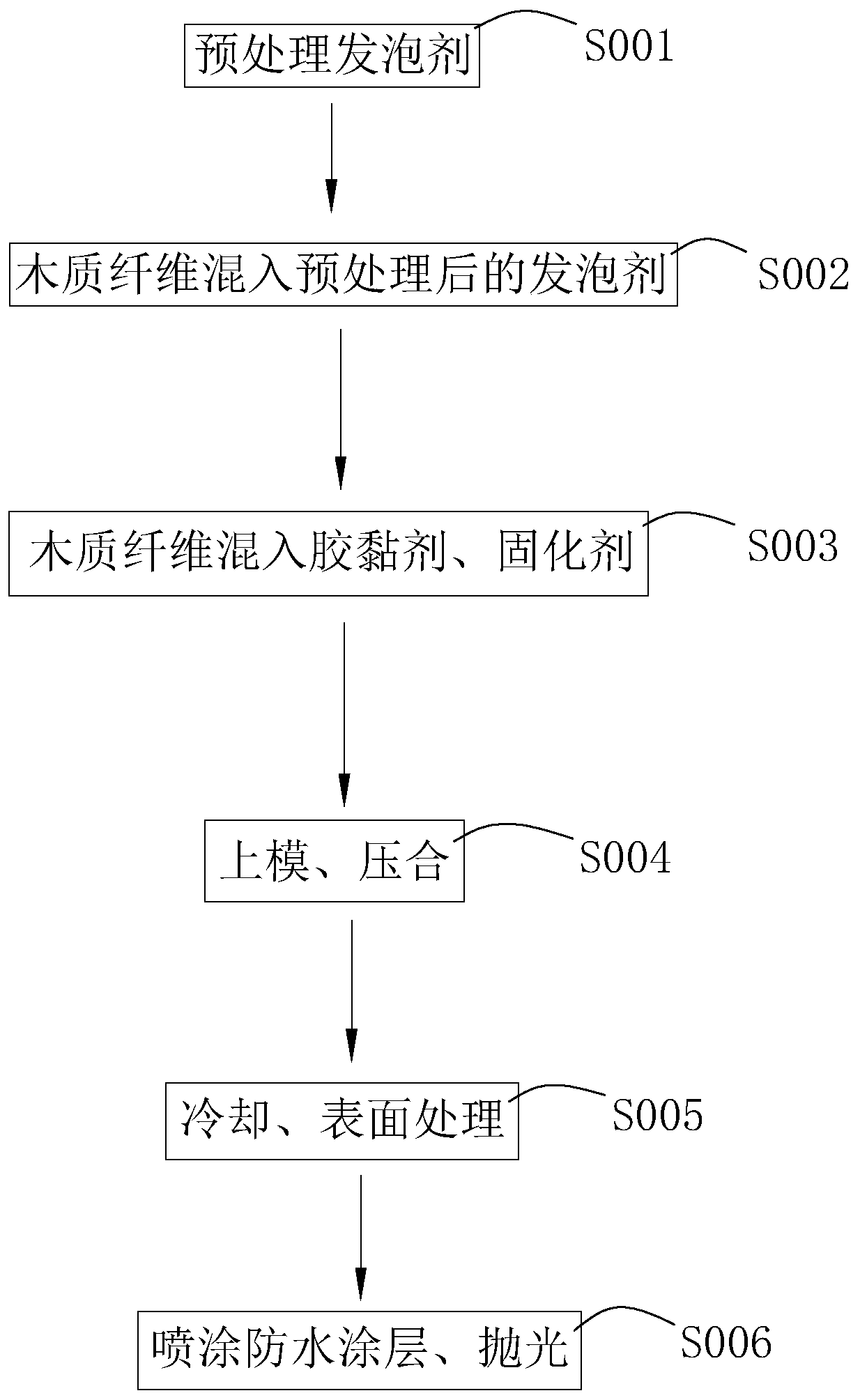

[0051] A method for preparing decorative fiberboard in Example 1, with reference to image 3 , including the following specific steps:

[0052] S001 pretreatment foaming agent, as follows:

[0053] Inject glue into the stirring tank and heat it to 35°C, then put the short glass fibers into the stirring tank and stir, so that all the short glass fibers are adhered to the glue, and then put the foaming agent carbonic acid into the high-speed roller mixer Sodium bicarbonate, and then put the short glass fiber adhered with glue into a high-speed roller mixer to stir, so that the sodium bicarbonate powder adheres to the short glass fiber, then discharge the sodium bicarbonate powder and the short glass fiber and sieve, The screened short glass fiber adhered with sodium bicarbonate powder was dried for later use.

[0054] By heating the glue to 35°C, the polymer chains in the glue are easier to move, which makes the glue easier to stir, and at the same time makes it easier for the...

Embodiment 3

[0080] A method for preparing decorative fiberboard in Example 1, the difference from Example 2 is:

[0081] The length of short glass fiber in S001 is 2mm.

[0082] Since the length of the short glass fiber is 2 mm, it is avoided that too much foaming agent is attached due to the short glass fiber being too long, resulting in too large micropores formed in the decorative fiberboard when the foaming agent foams, so as to avoid a large local strength of the decorative fiberboard. decline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com