Preparation system of organic polymer water treatment agent

A technology of organic polymer and water treatment agent, which is applied in the direction of control/regulation process, chemical/physical process, chemical/physical/physicochemical process, etc., and can solve the problem of long time-consuming organic polymer sewage treatment agent problem, to achieve the effect of shortening the production interval, short time consumption, and long time to solve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

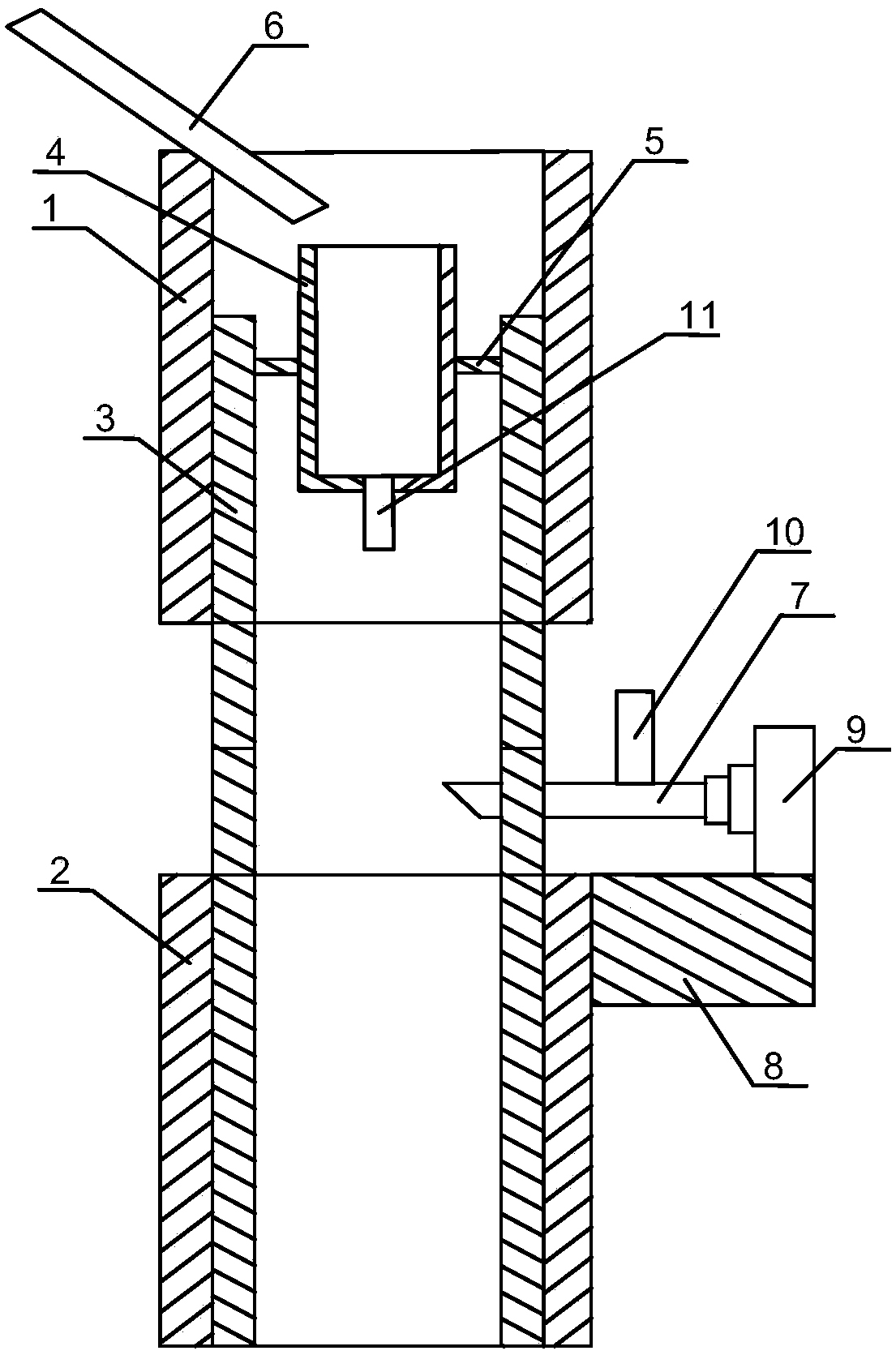

[0022] Such as figure 1 As shown, the preparation system of the organic polymer water treatment agent of the present invention includes a primary reaction cylinder 1, a secondary reaction cylinder 2 located below the primary reaction cylinder 1 and having the same central axis as the primary reaction cylinder 1, the first Both ends of the primary reaction cylinder 1 and both ends of the secondary reaction cylinder 2 are fully open, and two slide rails are arranged between the primary reaction cylinder 1 and the secondary reaction cylinder 2, which are symmetrical about the central axis of the primary reaction cylinder 1. 3. The slide rail 3 is fixed on the inner wall of the primary reaction cylinder 1 and the secondary reaction cylinder 2, and a bracket 5 for placing the sewage treatment agent reaction container 4 is arranged between the two slide rails 3, and the bracket 5 and the two The slide rail 3 on the side is slidingly connected, the slide rail 3 slides up and down alo...

Embodiment 2

[0025] Based on Example 1, a support seat 8 is provided on the side wall of the secondary reaction cylinder 2, and a horizontal telescopic column 9 is connected above the support seat 8, and the second feed pipe 7 is connected to the telescopic column 9. The second feeding pipe 7 is placed horizontally and is concentric and coaxial with the telescopic column 9 , and a feeding pipe 10 is communicated above the second feeding pipe 7 . The telescopic column 9 is an electric telescopic column. The telescopic column is used to control the distance between the outlet of the second feed pipe and the secondary reaction cylinder. When the sewage treatment agent reaction container slides down to the secondary reaction cylinder, the telescopic column is shortened to avoid the second feed pipe from obstructing the sewage The slide of the treatment agent reaction container is easy to use.

Embodiment 3

[0027] Based on the above embodiment, the slide rail 3 is an electric slide rail, a controller for controlling the driving device of the slide rail 3 is provided on the primary reaction cylinder 1, and a timing device is provided on the controller. The controller can set the timing. When the sewage treatment agent completes the first-stage reaction in the primary reaction cylinder, the controller turns on the driving device of the electric slide rail, so that the sewage treatment agent reaction container automatically slides down into the secondary reaction cylinder, realizing automatic control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com