Novel lubricating oil water separation oil purifier for warship

A water separation oil purifier and lubricating oil technology, which is applied in mechanical dehydration/emulsification, hydrocarbon oil treatment, filtration and separation, etc. It can solve the problems of large wear of mechanical parts, excessive wear of oil, and noise generation. To achieve the effect of prolonging service life, constant oil temperature and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

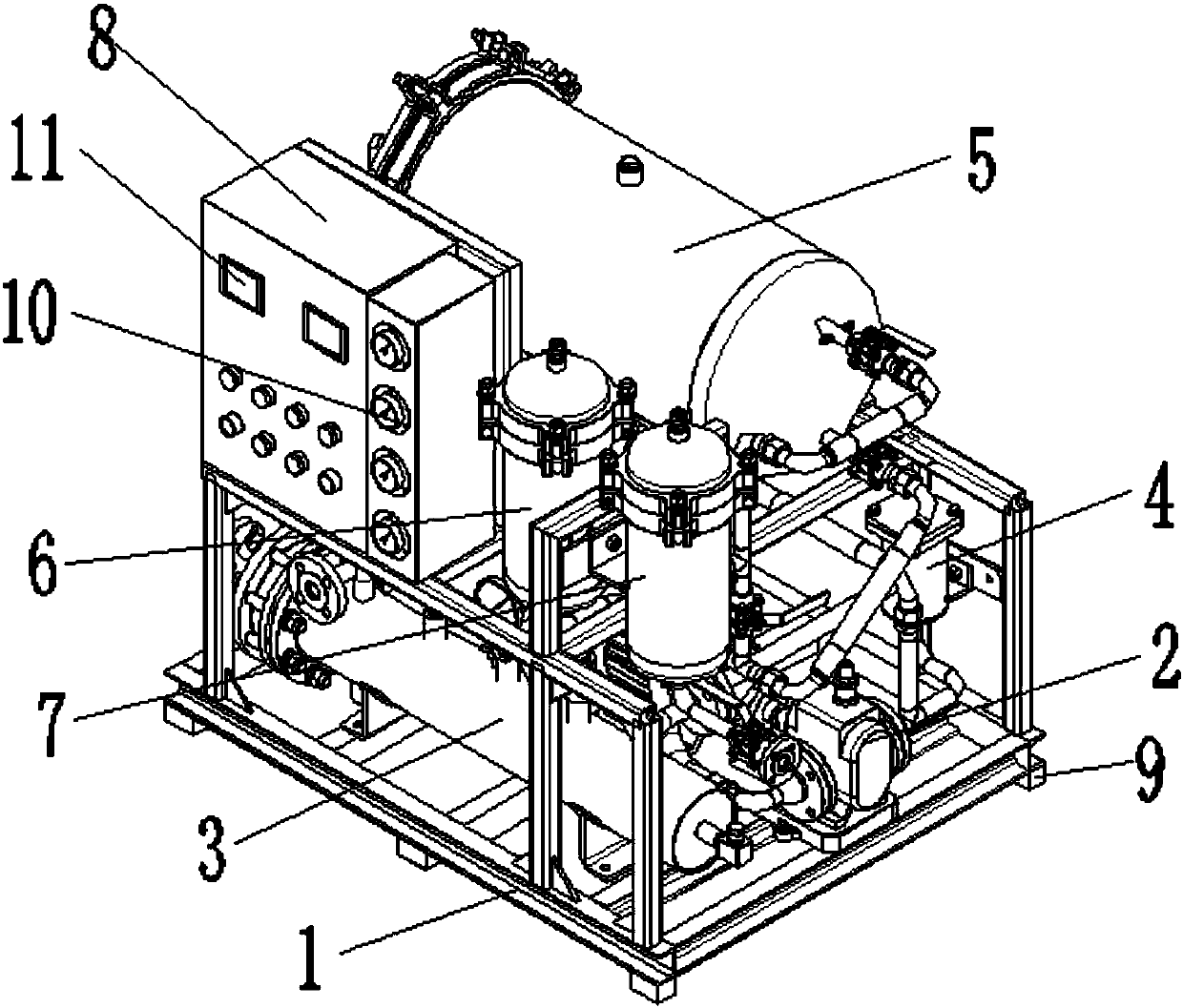

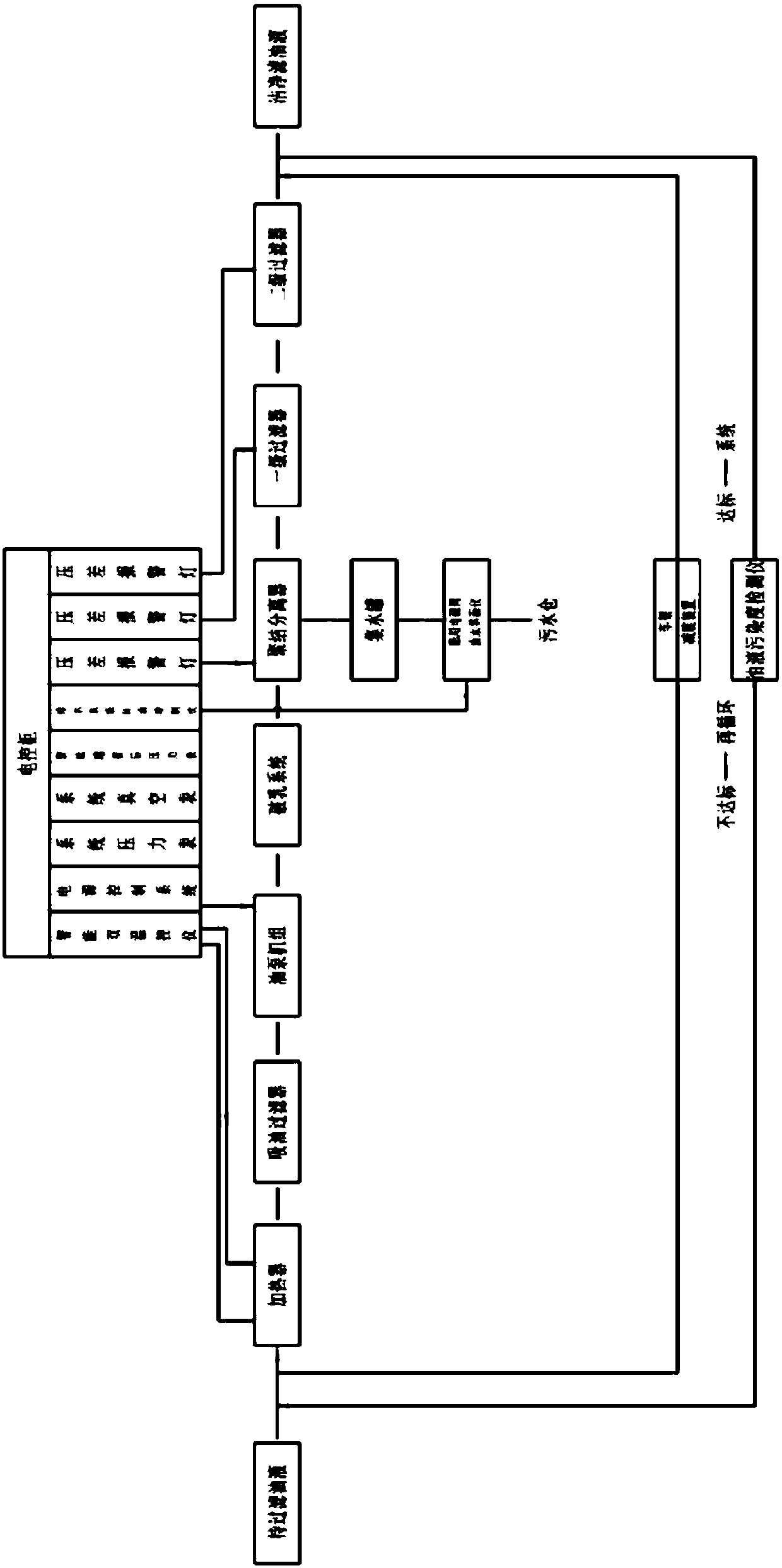

[0014] Such as figure 1 As shown, a new type of lubricating oil water separator and oil purifier for ships includes a frame 1 and an oil tank to be filtered, and the frame 1 is provided with an oil pump for extracting the oil to be filtered in the oil tank to be filtered 2. A heater 3 and an oil suction filter 4 are arranged between the oil pump 2 and the oil tank to be filtered. The oil pump 2 communicates with the coalescing separator 5 through the demulsification filter, and the coalescing separator 5 also The water collecting tank is connected with the pre-filter 6, the pre-filter 6 is connected with the fine filter 7, the water collecting tank is connected with the sewage bin through the electromagnetic valve, and the water collecting tank is also provided with oil and water The interface instrument also includes an oil pollution degree detector 11, the fine filter 7 communicates with the heater 3, the oil pollution degree detector 11 is arranged between the fine filter 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com