Double-frequency ultrasonic modification method of arrowhead starch

A technology of sagittarius starch and ultrasound, which is applied in the field of preparing sagittarius modified starch with dual-frequency ultrasound, can solve the problems of few reports and achieve the effects of short time-consuming, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

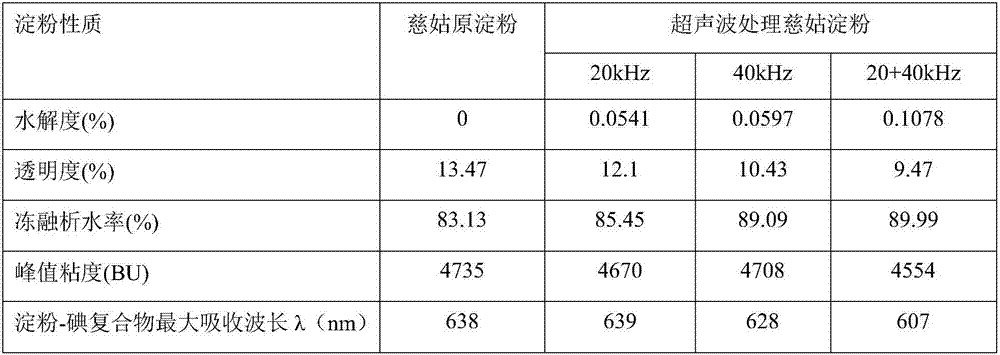

Embodiment 1

[0019] Weigh 16.68g of Arrowhead Starch with a water content of 10.08%, add 283mL of water, mix well, and prepare Arrowhead Starch Milk with a concentration of 5% (g / mL); put the evenly mixed Arrowhead Starch Milk in a beaker and place it in a dual-frequency ultrasonic device Ultrasonic treatment was carried out in the middle of the ultrasonic treatment, ultrasonic frequency 20+40kHz, ultrasonic power 300w, ultrasonic 10s, intermittent 2s, total ultrasonic time 40min, ultrasonic temperature 30 sound temperature, stir the arrowroot starch milk at the same time during the ultrasonic process; put the processed arrowroot starch milk After a period of time, the upper liquid was poured off, and the remaining starch was dried in a 50-hour drying oven to 7%-10%; the dried arrowroot starch was crushed with a pulverizer to obtain double-frequency ultrasonically modified arrowroot starch.

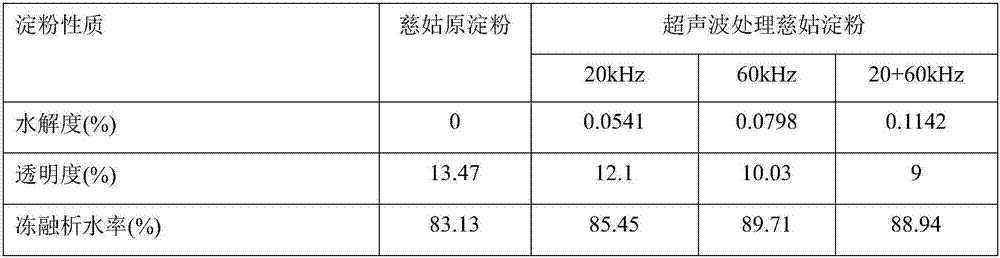

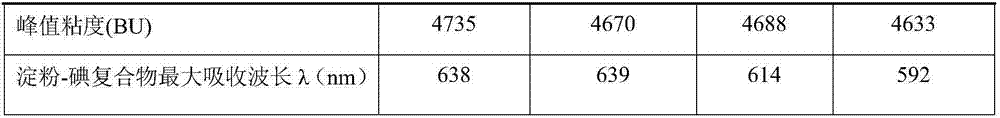

Embodiment 2

[0021] Weigh 16.68g of Arrowhead Starch with a water content of 10.08%, add 283mL of water, mix well, and prepare Arrowhead Starch Milk with a concentration of 5% (g / mL); put the evenly mixed Arrowhead Starch Milk in a beaker and place it in a dual-frequency ultrasonic device Ultrasonic treatment is carried out in the medium, and the ultrasonic frequency is 20+60kHz. The rest of the conditions were the same as in Example 1, and the arrowroot starch modified by dual-frequency ultrasonic was obtained.

Embodiment 3

[0023] Weigh 16.68g of Arrowhead Starch with a water content of 10.08%, add 283mL of water, mix well, and prepare Arrowhead Starch Milk with a concentration of 5% (g / mL); put the evenly mixed Arrowhead Starch Milk in a beaker and place it in a dual-frequency ultrasonic device Ultrasonic treatment was carried out in the middle, the ultrasonic frequency was 40+60kHz, and other conditions were the same as in Example 1, so as to obtain the arrowroot starch modified by dual-frequency ultrasonic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com