Neutron detector based on thick gem and multilayer boron-coated mesh

A neutron detector, boron-coated technology, applied in the direction of radiation intensity measurement, etc., can solve the problems of increased ignition damage, waste of boron 10 materials, pollution, etc., to increase the contact cross-sectional area, easy to control performance, and ensure conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

[0036] In order to solve the technical defects mentioned above in the background art, a neutron detector based on a Thick Gaseous Electron Multiplier (Thick Gaseous Electron Multiplier, THGEM, hereinafter referred to as thick GEM) is used in the embodiments of the present invention.

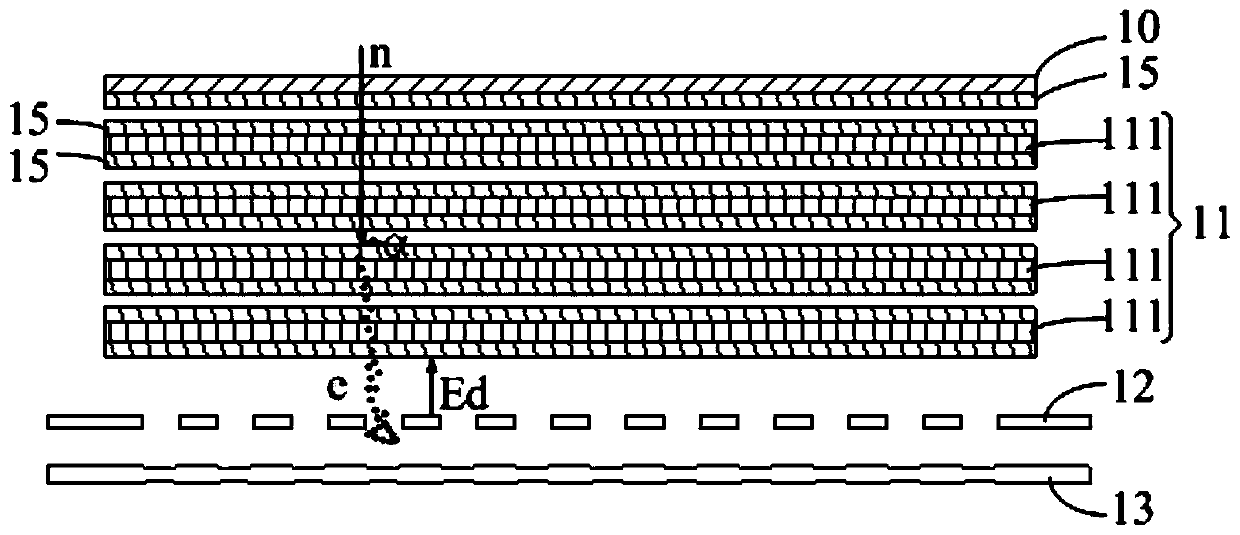

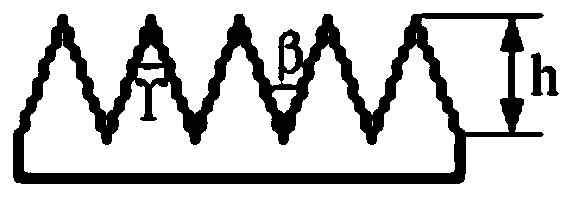

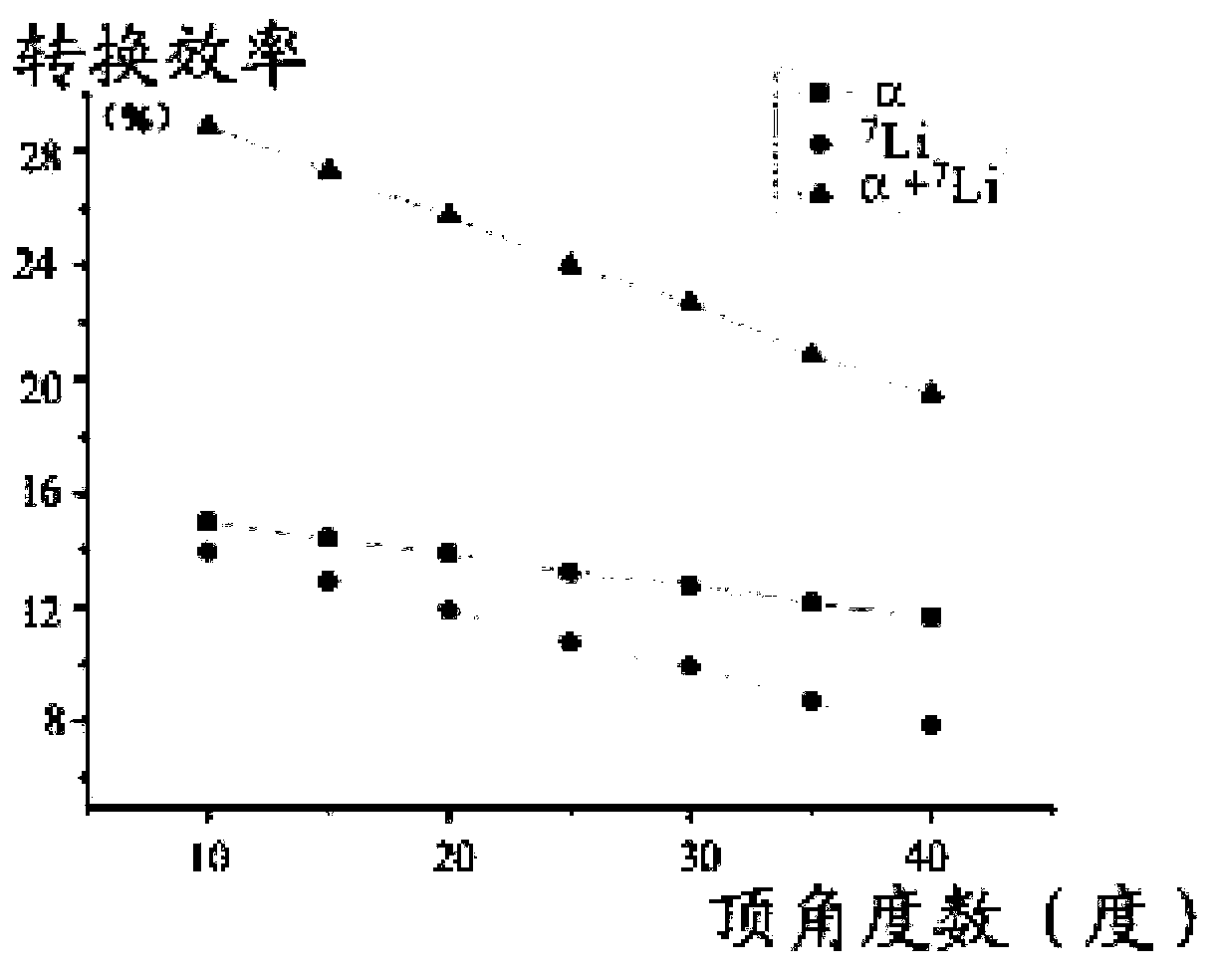

[0037] figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com