Test marking machine with code scanning device

A technology for marking and installing grooves, applied in the field of testing marking machines, can solve the problems of inability to contact the detection probe, low overall efficiency and quality, and marking of qualified products, so as to be suitable for mass production, easy to track and count, and detect. The effect of high efficiency and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

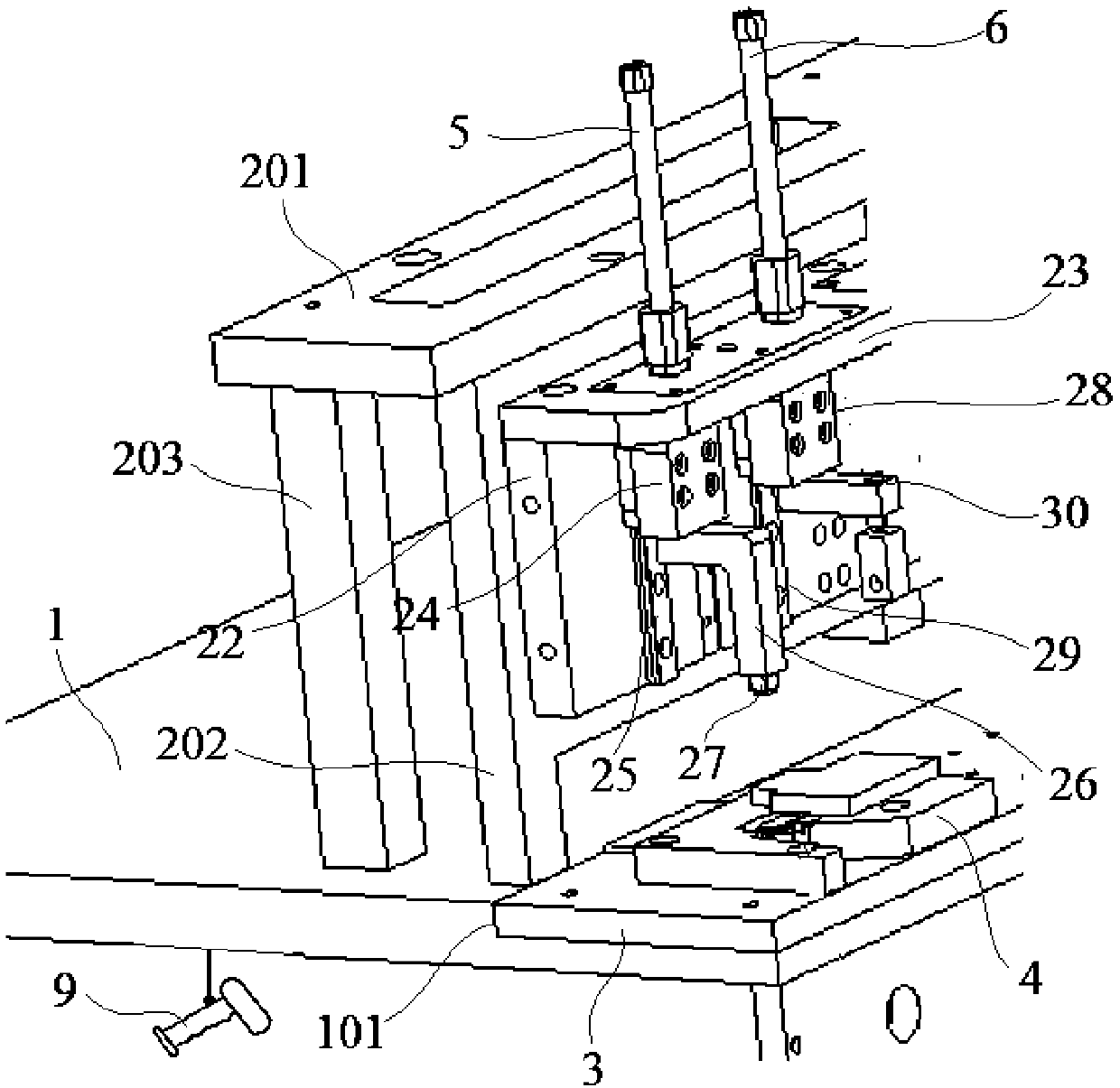

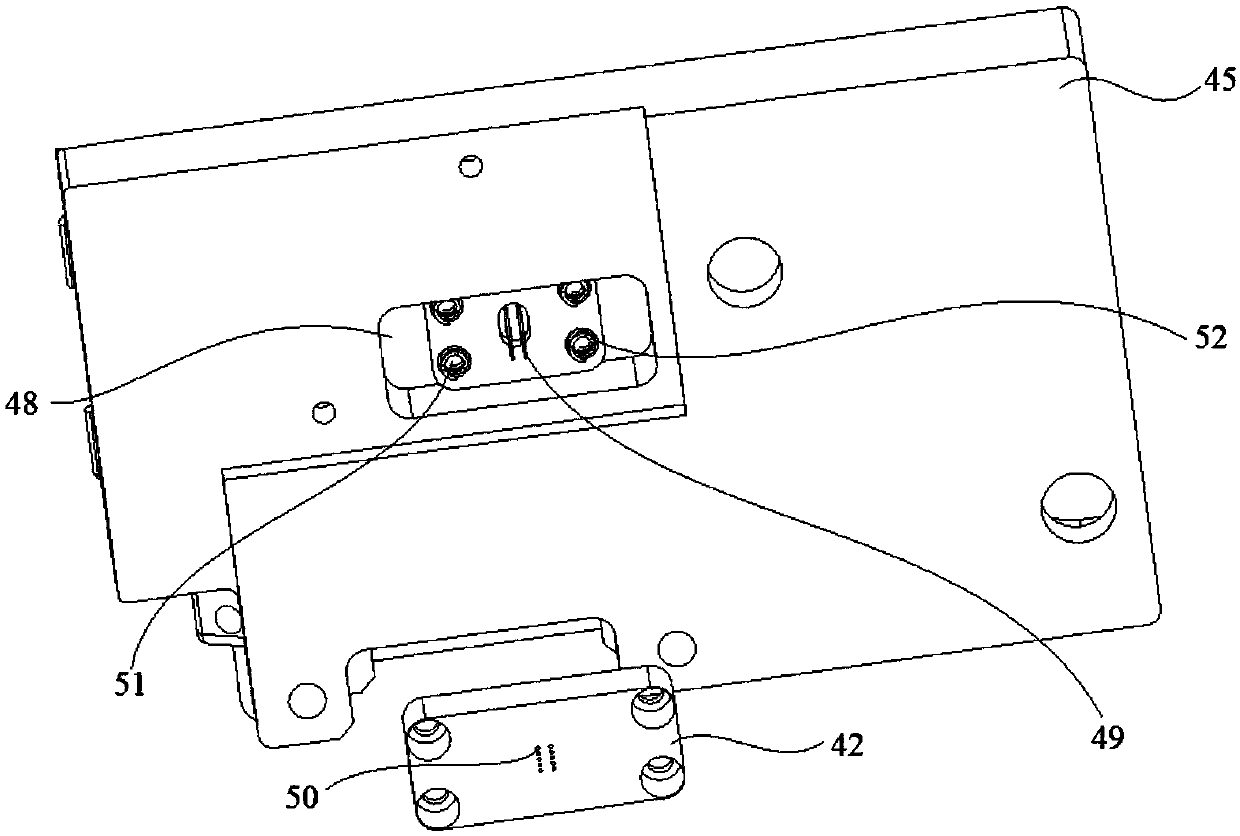

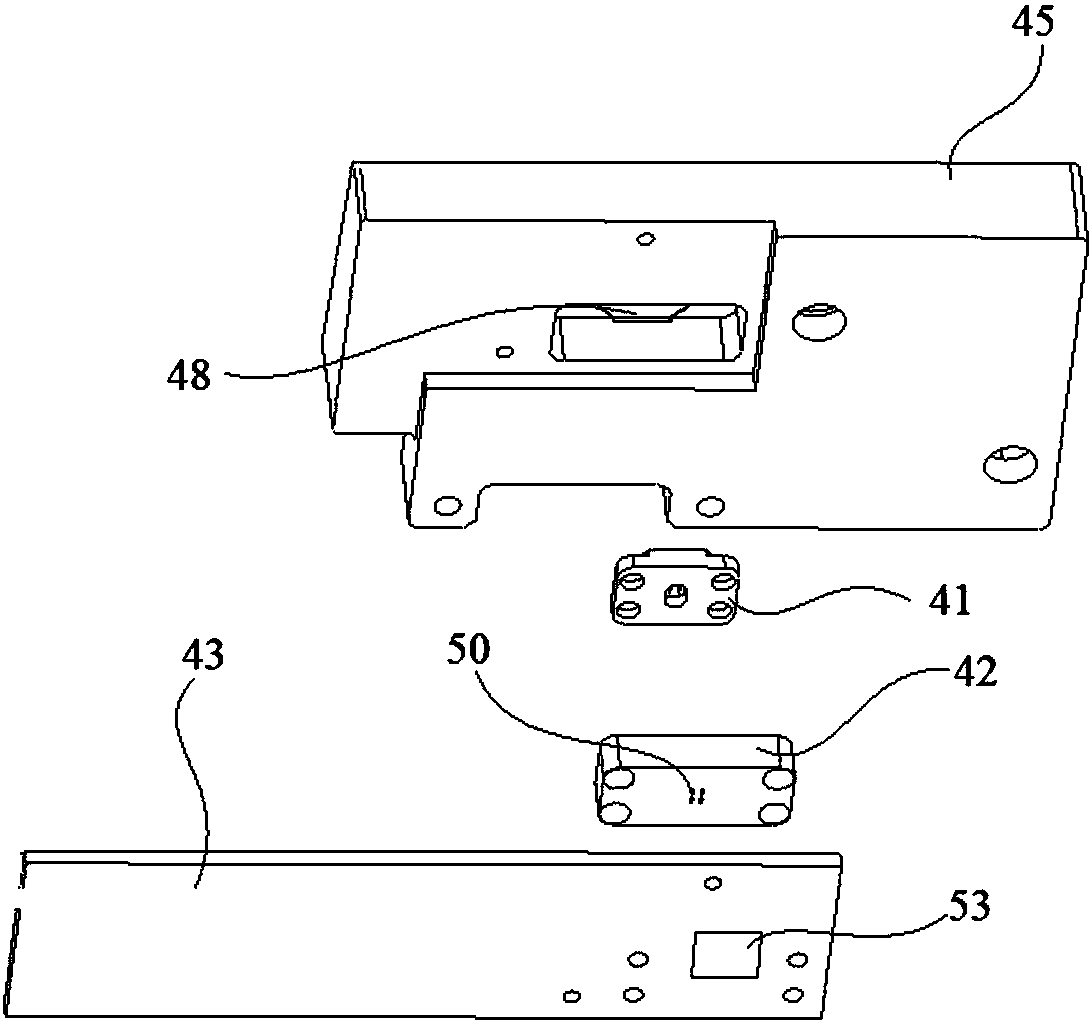

[0027] Embodiment 1: A test marking machine with a code scanning device, including a base 1, a bracket 2, a substrate 3, a test carrier 4, a test cylinder 5, a dotting cylinder 6 and a code scanning device 9, and the bracket 2 is installed on the base 1 upper surface, the base plate 3 is embedded in the installation groove 101 on one side of the base 1 and fixedly connected with the base 1, the test carrier 4 is installed on the upper surface of the base plate 3 by several bolts and is located under the test cylinder 5, the sweeper The code device 9 is installed on the base 1 through a support bracket 902;

[0028]The support bracket 902 is installed on the lower surface of the base 1, and the support bracket 902 is provided with a horizontal installation groove 909, and a motor 910 is fixedly installed in the installation groove 909, and the output end of the motor 910 is fixedly connected to There is a rotating shaft 911, the end of the rotating shaft 901 is fixedly connecte...

Embodiment 2

[0034] Embodiment 2: A test marking machine with a code scanning device, including a base 1, a bracket 2, a substrate 3, a test carrier 4, a test cylinder 5, a dotting cylinder 6 and a code scanning device 9, and the bracket 2 is installed on the base 1 upper surface, the base plate 3 is embedded in the installation groove 101 on one side of the base 1 and fixedly connected with the base 1, the test carrier 4 is installed on the upper surface of the base plate 3 by several bolts and is located under the test cylinder 5, the sweeper The code device 9 is installed on the base 1 through a support bracket 902;

[0035] The support bracket 902 is installed on the lower surface of the base 1, and the support bracket 902 is provided with a horizontal installation groove 909, and a motor 910 is fixedly installed in the installation groove 909, and the output end of the motor 910 is fixedly connected to There is a rotating shaft 911, the end of the rotating shaft 901 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com