Coal bed gas pressure monitoring system based on 6LoWPAN internet-of-things technology

A technology of coal seam gas pressure and Internet of Things technology, applied in signal transmission system, network topology, mining equipment and other directions, can solve the problems of low measurement accuracy, limited distribution, large workload, etc., to avoid chaos and disorder, and less human intervention. , the effect of large coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

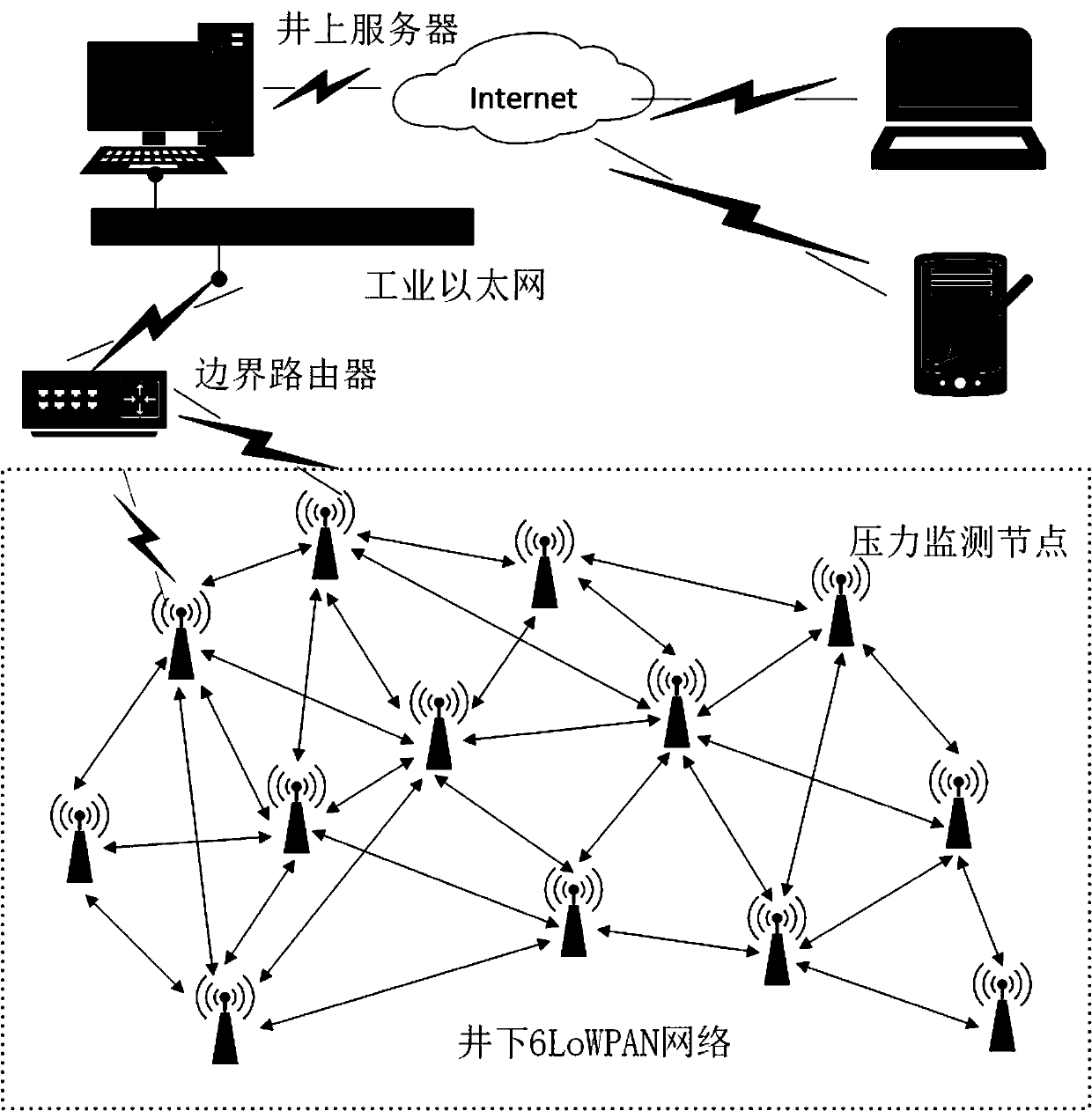

[0019] Such as figure 1 As shown, a coal seam gas pressure monitoring system based on 6LoWPAN Internet of Things technology includes an underground 6LoWPAN wireless sensor network, a border router, industrial Ethernet, an uphole server, a monitoring computer, and an intelligent terminal; the underground 6LoWPAN wireless sensor network is connected to the border router; The border router is connected to the server on the well through the industrial Ethernet; the monitoring computer and the intelligent terminal are connected to the server on the well through the Internet to obtain data from the server on the well; the underground 6LoWPAN wireless sensor network is provided with several pressure monitoring nodes.

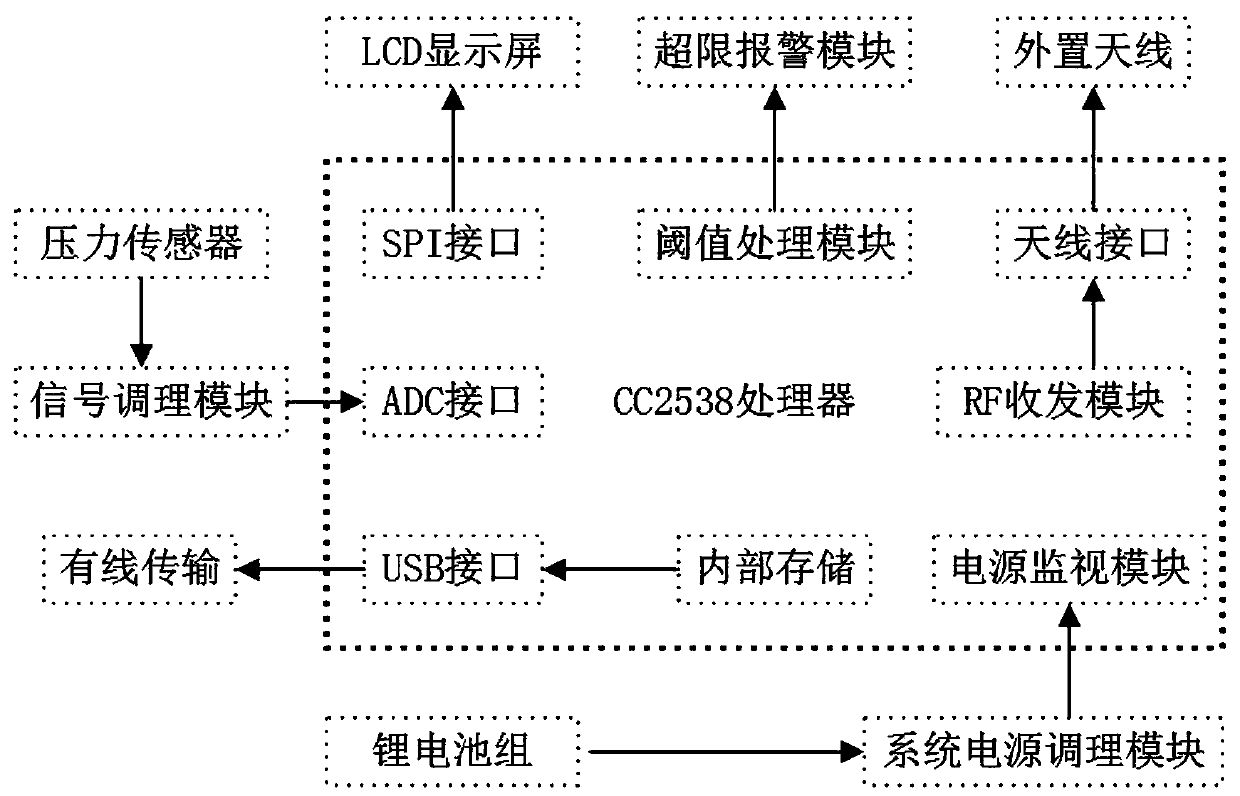

[0020] The pressure monitoring node is installed at the position of the coal seam gas pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com