A kind of polyurethane emulsion adhesive containing superfine talcum powder

A technology of ultra-fine talcum powder and polyurethane emulsion, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc. The effect of high initial adhesion strength, increasing crystallization speed and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

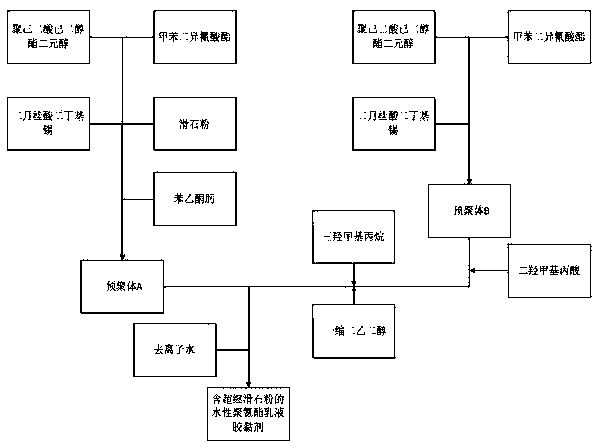

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Under the protection of nitrogen, add 1 mol of polyhexamethylene adipate diol and 2 mol of toluene diisocyanate, stir evenly, react at a temperature of 60°C for 3 hours, add 400g of polyhexamethylene adipate with an aspect ratio of 20:1 , with an average particle size of 1 μm and a specific surface area of 500m 2 / g of superfine talc powder, the surface hydroxyl number is 3.0 OH / nm 2 , add 2wt% of dibutyltin dilaurate, continue to stir at 90°C for 1h, then lower the temperature to 50°C, add 1 mol of acetophenone oxime, continue to stir for 2h to obtain prepolymer A, wherein, 2wt% Based on the sum of polyhexamethylene adipate diol and toluene diisocyanate;

[0024] Step 2: Under the protection of dry nitrogen, add 10 mol of polyhexamethylene adipate diol with a molecular weight of 4000 and 20 mol of toluene diisocyanate into the reactor, heat at 60°C, stir for 2 hours, and add 2wt% dilaurel Dibutyltin acid, continue to stir 2 h, obtain prepolymer B, wherein, ...

Embodiment 2

[0029] Repeat the method of Example 1 according to the specified content of each component, but the temperature of the first section in step one is 70 ° C, and the stirring time is 2 h; the temperature of the second section is 80 ° C, and the stirring time is 2 h; The temperature of the first stage is 60°C, the stirring time is 2h, and the viscosity is adjusted to 4000mPa·s.

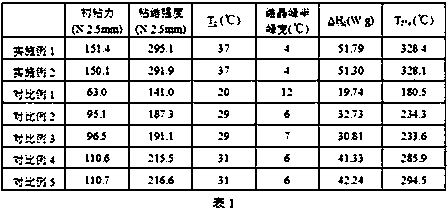

[0030] The properties of the adhesive are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com