Novel high-strength high alumina porcelain insulator

A porcelain insulator, high-strength technology, applied in the field of new high-strength high-alumina porcelain insulators, can solve the problems of low mechanical strength, poor electrical and thermal performance of electric porcelain machines, and inability to greatly improve the bending strength of porcelain, etc. , to improve process performance, shorten ball milling time, and facilitate process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

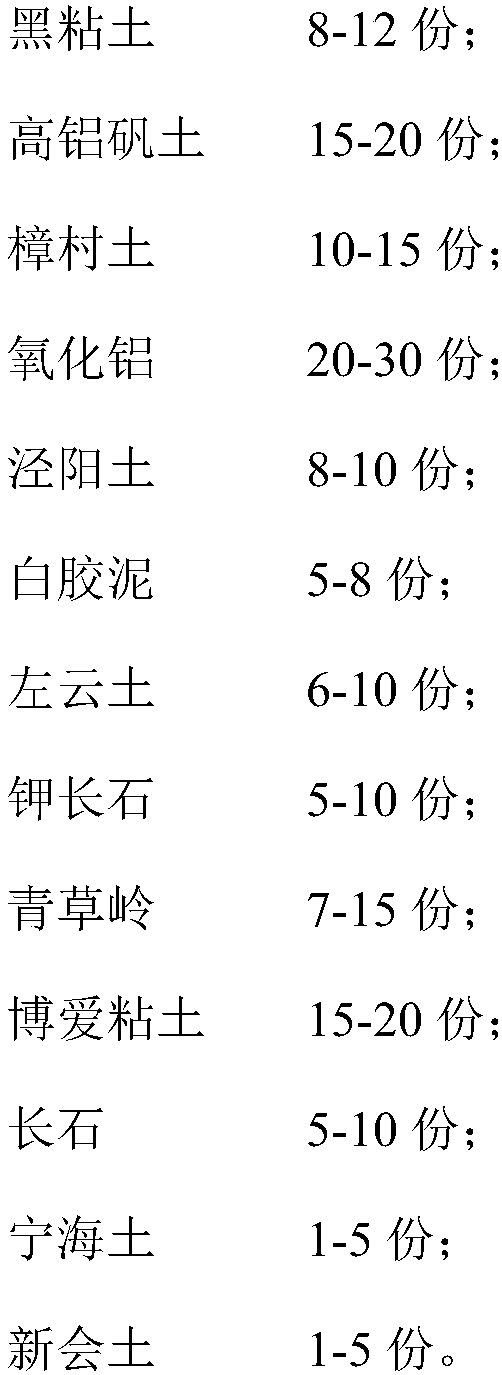

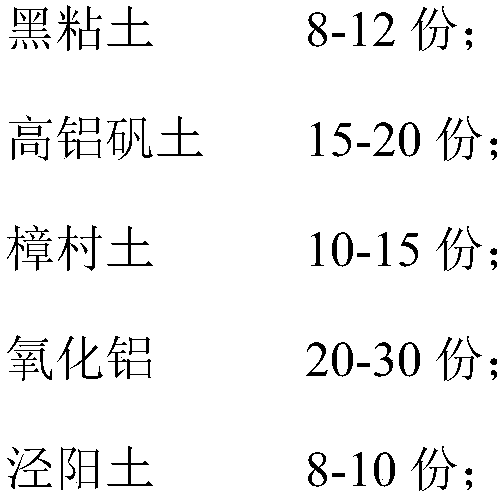

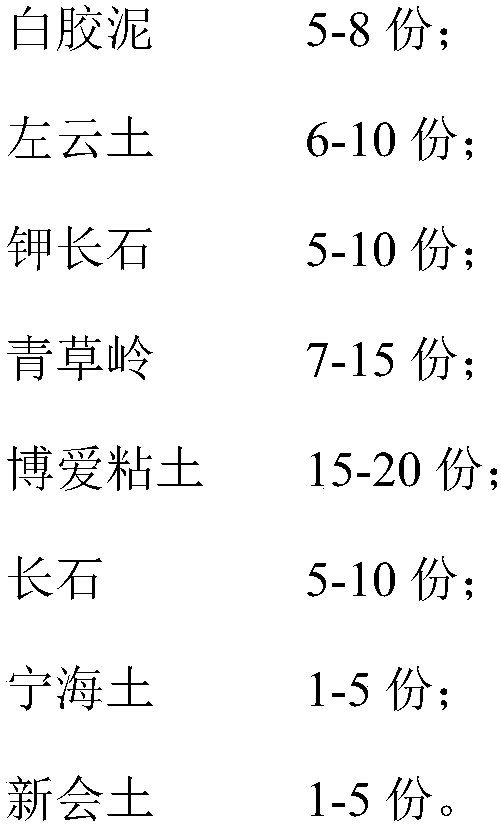

[0026] Example 1: A new type of high-strength high-alumina porcelain insulator, which is made of the following raw material formula in parts by weight: 9 parts of black clay, 16 parts of high-alumina bauxite, 11 parts of Zhangcun soil, 20 parts of alumina, Jingyang 8 parts of clay, 6 parts of white clay, 7 parts of zuoyun soil, 5 parts of potassium feldspar; 7 parts of Qingcaoling, 15 parts of Boai clay, 6 parts of feldspar, 2 parts of Ninghai soil, and 2 parts of Xinhui soil. The preparation process of the new high-strength high-alumina porcelain insulator is as follows:

[0027] S1: First, weigh the above raw materials according to the prepared ratio, add water of 35% of the total weight of the base material to obtain a slurry, and then ball mill the slurry for 9-10 hours to obtain a new slurry, preferably new slurry particles The number of meshes does not exceed 200 meshes;

[0028] S2: The new slurry obtained in step 1 is sieved to remove coarse particles and tailings, an...

Embodiment 2

[0037] Example 2: A new type of high-strength high-alumina porcelain insulator, which is made of the following raw material formula in parts by weight: 10 parts of black clay, 18 parts of high-alumina bauxite, 13 parts of Zhangcun soil, 25 parts of alumina, Jingyang 9 parts of soil, 6 parts of white clay, 7 parts of zuoyun soil, 7 parts of potassium feldspar; 9 parts of Qingcaoling, 18 parts of Bo'ai clay, 8 parts of feldspar, 2 parts of Ninghai soil, and 2 parts of Xinhui soil. The preparation process of the new high-strength high-alumina porcelain insulator is as follows:

[0038] S1: First, weigh the above raw materials according to the prepared ratio, add water of 35% of the total weight of the base material to obtain a slurry, and then ball mill the slurry for 9-10 hours to obtain a new slurry, preferably new slurry particles The number of meshes does not exceed 200 meshes;

[0039] S2: The new slurry obtained in step 1 is sieved to remove coarse particles and tailings, ...

Embodiment 3

[0048] Example 3: A new type of high-strength high-alumina porcelain insulator, made of the following raw material formula in parts by weight: 10 parts of black clay, 20 parts of high-alumina bauxite, 14 parts of Zhangcun soil, 28 parts of alumina, Jingyang 9 parts of soil, 6 parts of white clay, 7 parts of zuoyun soil, 8 parts of potassium feldspar; 10 parts of Qingcaoling, 18 parts of Bo'ai clay, 8 parts of feldspar, 3 parts of Ninghai soil, and 3 parts of Xinhui soil. The preparation process of the new high-strength high-alumina porcelain insulator is as follows:

[0049] S1: First, weigh the above raw materials according to the prepared ratio, add water of 35% of the total weight of the base material to obtain a slurry, and then ball mill the slurry for 9-10 hours to obtain a new slurry, preferably new slurry particles The number of meshes does not exceed 200 meshes;

[0050] S2: The new slurry obtained in step 1 is sieved to remove coarse particles and tailings, and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com