Ultra-light film-coated proppant and preparation method thereof

A proppant and ultra-light technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of reduced conductivity of rock formation cracks, high brittleness of phenolic resin coating, uneven laying process, etc. , to achieve the effects of good preparation process controllability, uniform laying process and good convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

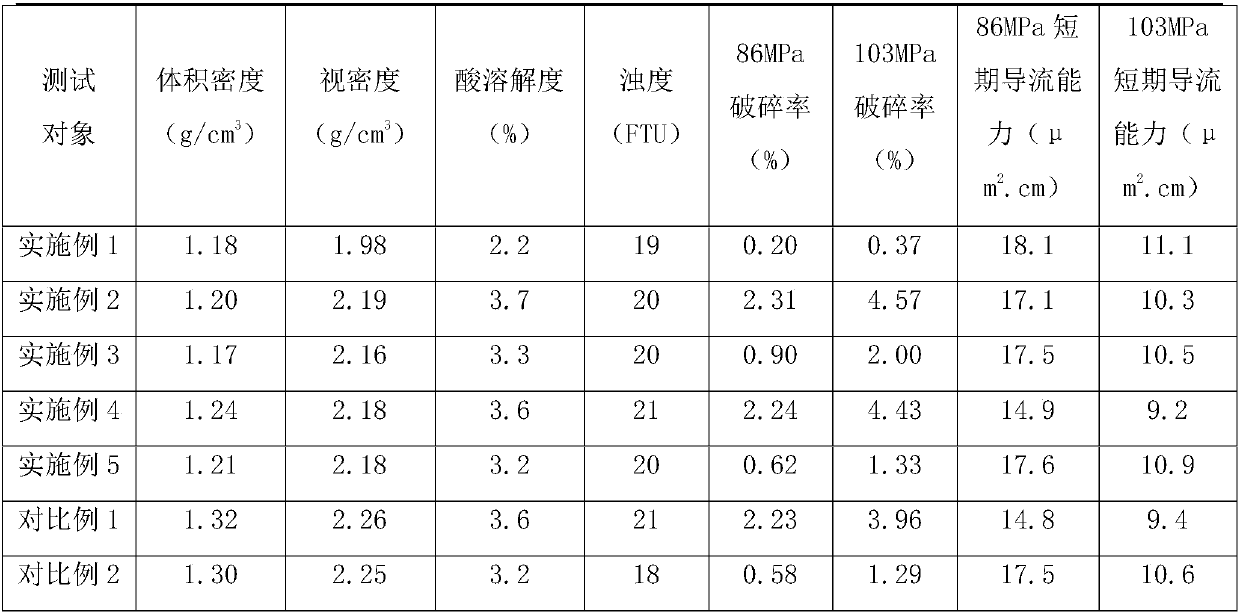

Examples

Embodiment 1

[0026] 1) Heat 100kg of aggregate to 350°C; wherein the aggregate is one or more of ceramsite, quartz sand or walnut shell, ceramsite is preferred in this embodiment, the particle size of ceramsite is preferably 40 / 70 mesh, and the volume The density is preferably 1.3g / cm 3 , the apparent density is preferably 2.65g / cm 3 .

[0027] 2) Add 20kg of special resin, stir and coat with the aggregate, then add 10kg of curing agent and 6kg of accelerator, stir and mix evenly, and then cure.

[0028] The production method of the special resin is as follows: heat the resin and sub-nanometer inorganic materials to 200 ° C, and mix for 10 minutes; the resin includes phenolic resin, epoxy resin and silicone resin, and phenolic resin, epoxy resin, silicone resin and sub-nanometer The masses of the inorganic materials are 5kg, 6.25kg, 6.25kg, and 2.5kg, respectively. The sub-nanometer inorganic material is one or more of silica micropowder, nano-silicon micropowder, nano-alumina powder, g...

Embodiment 2

[0035] 1) After heating 100kg of aggregate to 130°C; the aggregate is preferably ceramsite, the particle size of ceramsite is preferably 40 / 70 mesh, and the bulk density is preferably 1.3g / cm 3 , the apparent density is preferably 2.65g / cm 3 .

[0036] 2) Add 1kg of special resin, stir and coat with the aggregate, then add 0.003kg of curing agent and 0.001kg of accelerator, stir and mix, and then cure.

[0037] The production method of the special resin is as follows: heat the resin and the sub-nanometer inorganic material to 80°C, and mix for 1 minute; the resin includes phenolic resin, epoxy resin and silicone resin, and the phenolic resin, epoxy resin, silicone resin and sub-nanometer The masses of the inorganic materials are 0.2kg, 0.4kg, 0.3kg, and 0.1kg, respectively. The sub-nanometer inorganic material is one or more of silicon micropowder, nano-silicon micropowder, nano-alumina powder, glass microspheres, fly ash, and floating pearl powder, and the particle size of ...

Embodiment 3

[0044] 1) Heat 100kg of aggregate to 300°C; the aggregate is preferably ceramsite, the particle size of ceramsite is preferably 40 / 70 mesh, and the bulk density is preferably 1.3g / cm 3 , the apparent density is preferably 2.65g / cm 3 .

[0045] 2) Add 4.5kg of special resin, stir and coat with the aggregate, then add 2.0kg of curing agent and 0.8kg of accelerator, stir and mix, and then cure.

[0046] The production method of the special resin is: heat the resin and sub-nanometer inorganic materials to 100°C, and mix for 5 minutes; the resin includes phenolic resin, epoxy resin and silicone resin, and phenolic resin, epoxy resin, silicone resin and sub-nanometer The masses of the inorganic materials are 1kg, 1.5kg, 1.5kg, and 0.5kg, respectively. The sub-nanometer inorganic material is one or more of silicon micropowder, nano-silicon micropowder, nano-alumina powder, glass microspheres, fly ash, and floating pearl powder, and the particle size of the sub-nano inorganic materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com