Finished oil depot sewage treatment system and sewage treatment method thereof

A sewage treatment system and oil depot technology, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of oil recovery without consideration, and achieve the effect of reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

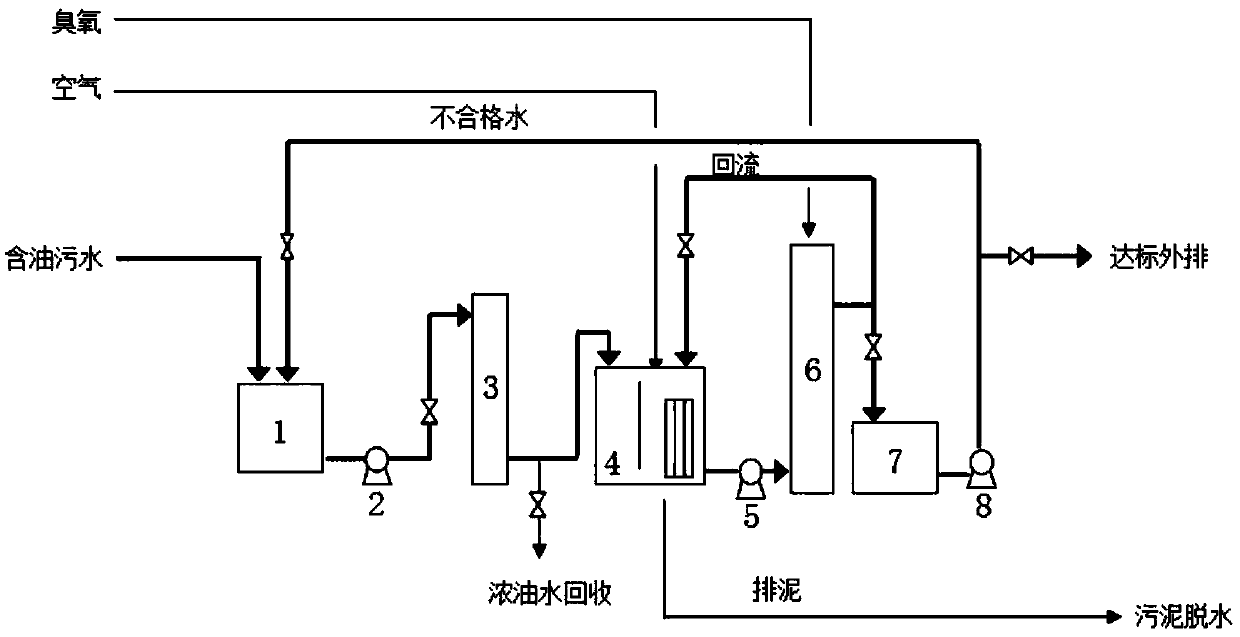

Embodiment 1

[0036] The technology of the present invention is used to treat the diesel tank cutting water of Offshore Oil Yangjiang Industrial Co., Ltd., and the treatment scale is 4.5m 3 / h. The oily sewage is homogeneously regulated in the regulating tank 1 and then lifted to the ceramic-based functional membrane device 3 by the functional membrane inlet pump 2, and the flow rate of the oily concentrated water is controlled at 1.5m 3 / h, the flow rate of product water is 3m 3 / h, the concentration ratio is 3, and the water production rate reaches 66.7%; the produced water enters the integrated membrane bioreactor 4 together with the reflux water from the ozone catalytic oxidation tower 6, and the hydrolysis and acidification section, the aerobic section and the membrane bioreactor section. The hydraulic retention time is 18h, 12h and 6h respectively; the water from the membrane bioreaction section reaches the ozone catalytic oxidation tower 6, the hydraulic retention time is 3h, the oz...

Embodiment 2

[0039] Adopt the technology of the present invention to process the cutting water of the gasoline tank of CNOOC Yangjiang Industrial Co., Ltd., and the treatment scale is 5m 3 / h. The cutting water of the gasoline tank is mixed in the regulating tank 1 and then lifted to the ceramic-based functional membrane device 3 by the functional membrane water inlet pump 2, and the flow rate of the oily concentrated water is controlled at 0.5m 3 / h, the water flow rate is 4.5m 3 / h, the concentration ratio is 10, and the water production rate reaches 90%; the produced water enters the integrated membrane bioreactor 4 together with the reflux water from the ozone catalytic oxidation tower 6, and the hydrolytic acidification section, the aerobic section and the membrane bioreaction section The hydraulic retention times are 12h, 8h and 4h respectively; the water from the membrane bioreaction section reaches the ozone catalytic oxidation tower 6, the hydraulic retention time is 2h, the ozon...

Embodiment 3

[0042] The technology of the present invention is used to treat the mixed sewage of gasoline tank cutting water and diesel tank cutting water of Offshore Oil Yangjiang Industrial Co., Ltd. The two kinds of sewage are mixed at a ratio of 1:1, and the total amount of sewage is 4.2m 3 / h. The two kinds of sewage are mixed in the regulating tank 1, and are lifted to the ceramic-based functional membrane device 3 by the functional membrane inlet pump 2, and the flow rate of the oily concentrated water is controlled at 0.6m 3 / h, the flow rate of product water is 3.6m 3 / h, the concentration ratio is 7, and the water production rate reaches 85.7%; the produced water enters the integrated membrane bioreactor 4 together with the reflux water from the ozone catalytic oxidation tower 6, and enters the integrated membrane bioreactor 4 in the hydrolytic acidification section, aerobic section and membrane bioreaction section The hydraulic retention times are 15h, 9.6h and 4.8h respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com