Coconut shell-mud composite active carbon as well as preparation method and application thereof

A composite activated carbon and coconut shell technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low micropore ratio and small specific surface area, and achieve developed pores and specific surface area Large, high adsorption value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of coconut shell-sludge composite activated carbon, comprises the following steps:

[0027] (1) drying and crushing the remaining sludge from urban sewage treatment in sequence to obtain sludge particles;

[0028] (2) the sludge granules obtained in the step (1) are mixed with coconut shell granules to obtain a granule mixture;

[0029] (3) carbonizing the particle mixture obtained in the step (2) to obtain a carbonized product;

[0030] (4) drying the carbonized product, potassium hydroxide and water obtained in the step (3) to obtain an intermediate product;

[0031] (5) carbonizing and activating the intermediate product obtained in the step (4) to obtain activated carbide;

[0032] (6) The activated carbon obtained in the step (5) is washed successively with hydrochloric acid and water to obtain coconut shell-sludge composite activated carbon.

[0033] The invention sequentially dries and pulverizes the excess s...

Embodiment 1

[0062] Send the remaining sludge from urban sewage treatment plants with a moisture content of more than 85% into an oven to dry until the moisture content is lower than 10% to obtain dry sludge; grind the dry sludge and coconut shells separately, and sieve through 50 meshes to obtain a particle size not exceeding For 0.3mm sludge particles and coconut shell particles, weigh 10g of dry sludge and 10g of coconut shell particles according to the mass ratio of 1:1, and mix them evenly. The rest of the preparation methods are the same as in Example 1 to prepare coconut shell-sludge activated carbon.

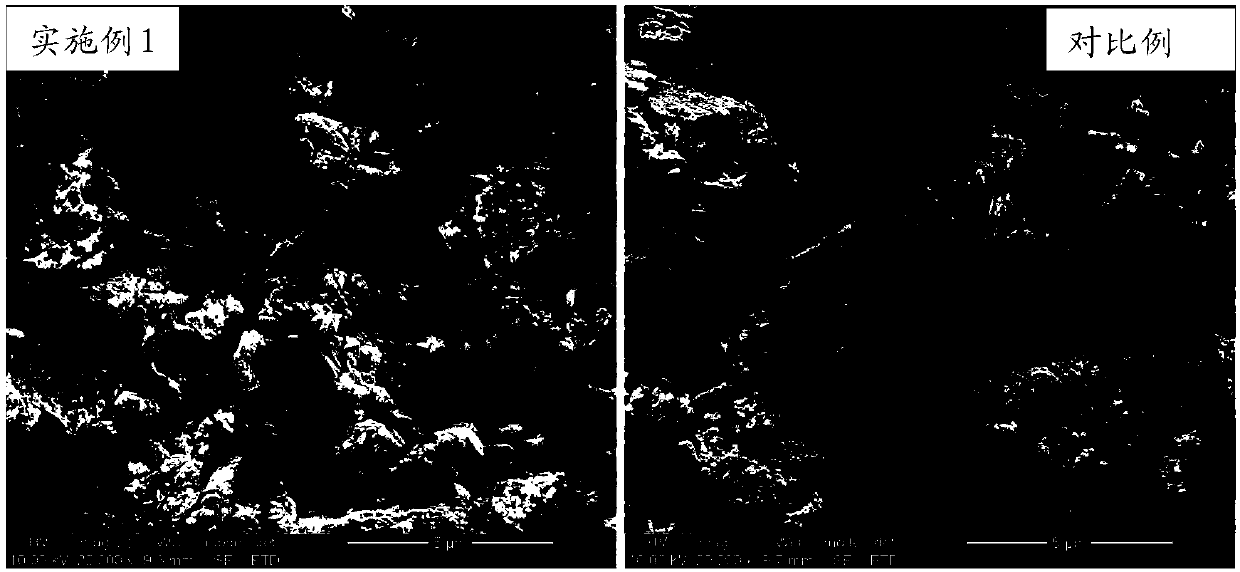

[0063] figure 1 The SEM image of the coconut shell-sludge composite activated carbon that the conventional sludge activated carbon that comparative example of the present invention makes and embodiment 1 make; figure 2 The BET image (test condition: analysis temperature 77.350K, adsorption and desorption time 6 hours) of the coconut shell-sludge composite activated carbon that the ...

Embodiment 2

[0065] (1) Send the remaining sludge of urban sewage treatment plants with a water content of more than 85% into an oven to dry until the water content is lower than 10% to obtain dry sludge; crush the dry sludge and coconut shells separately, and sieve through 50 meshes to obtain granules For sludge particles and coconut shell particles with a diameter not exceeding 0.3mm, weigh 10g of dry sludge and 10g of coconut shell particles according to the mass ratio of 1:1, and mix them evenly.

[0066] (2) Send the above sludge particles into a box-type resistance furnace, carbonize and activate at a temperature of 500° C. for 45 minutes, and control the heating rate at 35° C. / min to obtain carbonized products.

[0067] (3) Add the charred product obtained in step 2 into the potassium hydroxide solution and stir evenly, the concentration of potassium hydroxide is 2mol / L, and the impregnation ratio is 1:1.5 (mass ratio, W solid: W potassium hydroxide=1: 1.5, the same below), immerse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com