Tube-core-type composite board and bearing material for building

A composite board and tube core technology, used in building materials, buildings, building components, etc., can solve the problems of increasing the labor intensity of construction personnel, waste of materials, and hidden safety hazards, and achieve lightweight, material saving, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

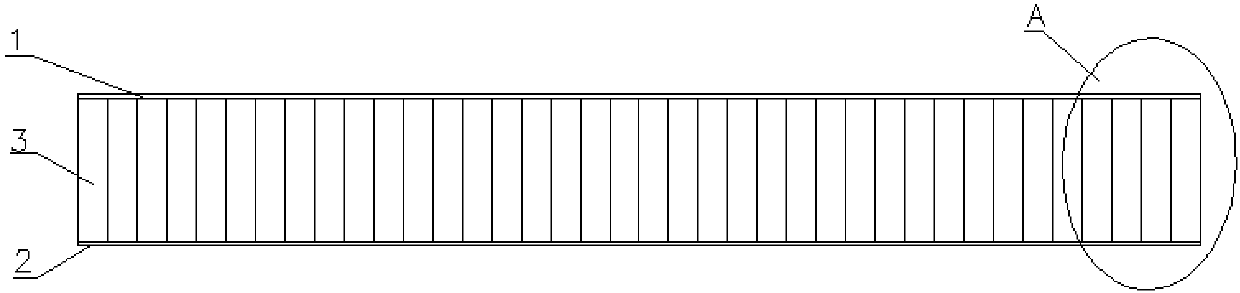

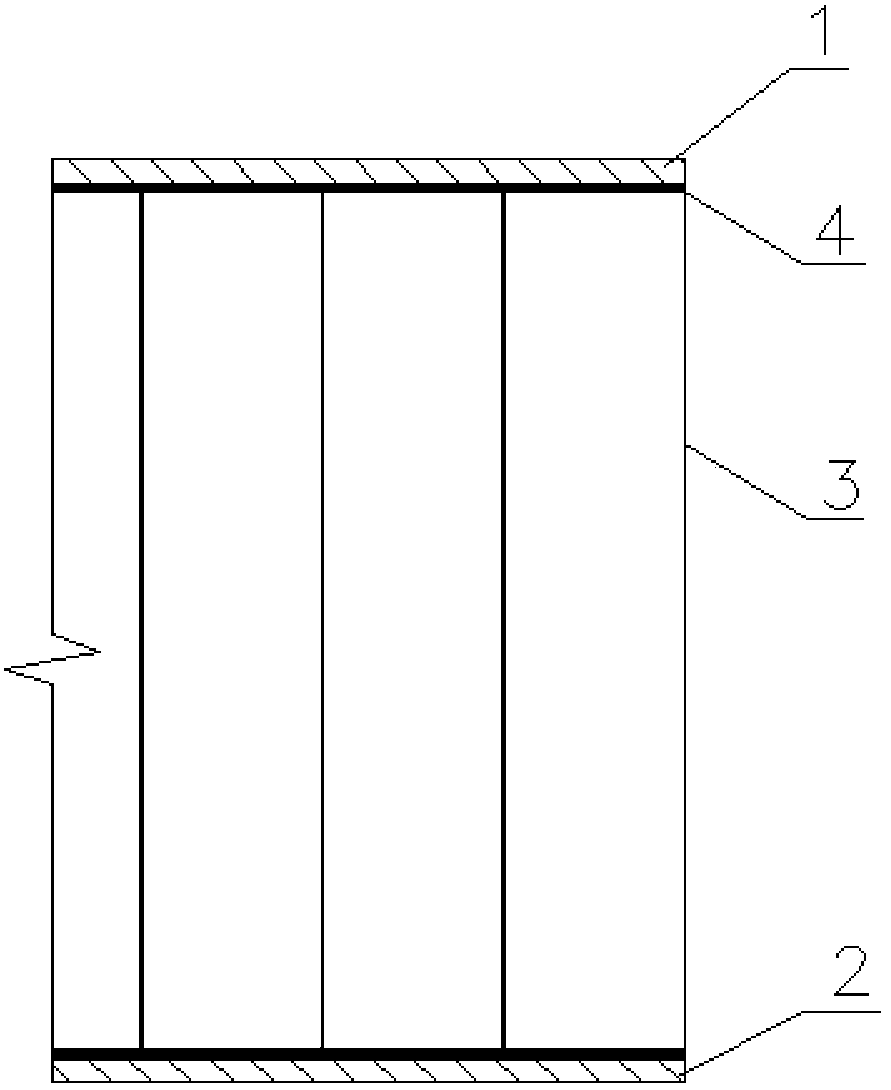

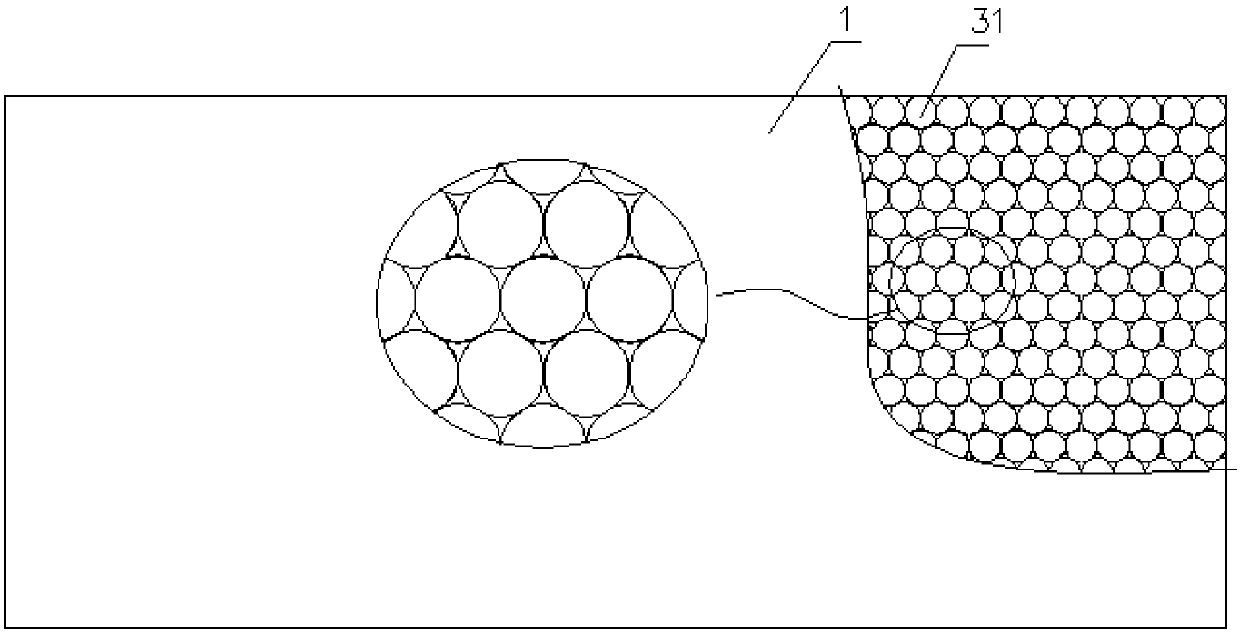

[0029] Such as Figure 1~Figure 4 Shown: a tube-core composite board, including an upper panel 1, a lower panel 2 and a tube core layer 3 arranged between them. , The lower panel 2 is connected by brazing to form a whole.

[0030] Wherein, both the upper panel 1 and the lower panel 2 are stainless steel plates, and the circular tube 31 is a stainless steel tube. The tube wall thickness of the circular tube 31 is 0.2 mm, and the thickness δ of the upper panel 1 and the lower panel 2 is 1 mm.

[0031] The sides of the adjacent round tubes 31 are squeezed and compressed to 2% to prevent gaps, and the squeezed round tubes 31 are pressed by the pressing plate to prevent gaps during the composite plate forming process.

[0032] After the upper panel 1 and the lower panel 2 sandwich the tube core layer 3, they are heated by brazing to heat and melt the brazing material, and the melted brazing material makes the top of the round tube 31 penetrate into the bodies of the upper panel 1...

Embodiment 2

[0035] A tube-core composite board, including an upper panel, a lower panel, and a tube core layer arranged between them. The tube core layer is formed by arranging and squeezing several round tubes and connecting the upper panel and the lower panel by brazing. a whole.

[0036] Among them, the upper panel and the lower panel are both carbon plates, and the round tubes are stainless steel tubes. The wall thickness of the round pipe is 1mm, and the thickness of the upper plate is δ 1 3mm, lower panel thickness δ 2 1mm.

[0037] The sides of adjacent circular tubes are squeezed and compressed with a compression amount of 4% to prevent gaps.

[0038] The upper panel, the lower panel and the die layer are formed by bonding, such as epoxy glue, polyurethane glue, etc. The thickness of the bonded layer formed after bonding is 1mm.

[0039] The tube-core composite board is suitable for making columns or beams capable of bearing loads of building materials, and is more suitable f...

Embodiment 3

[0041] The difference from Example 1 or Example 2 is that the wall thickness of the round tube is 1.5 mm, and the thickness of the upper panel is δ 1 5mm, lower panel thickness δ 2 is 2mm.

[0042] Others are the same as embodiment 1 or embodiment 2.

[0043] The tube-core composite board is suitable for making a column or beam capable of bearing load of building materials, and is more suitable for high floors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com