Method for reducing gasoline sulfur content

A sulfur content, gasoline technology, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of large octane number loss, increase in octane number loss, and increase in the proportion of heavy gasoline, and achieve octane The effects of small loss value, reduced energy consumption and operating costs, and increased effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

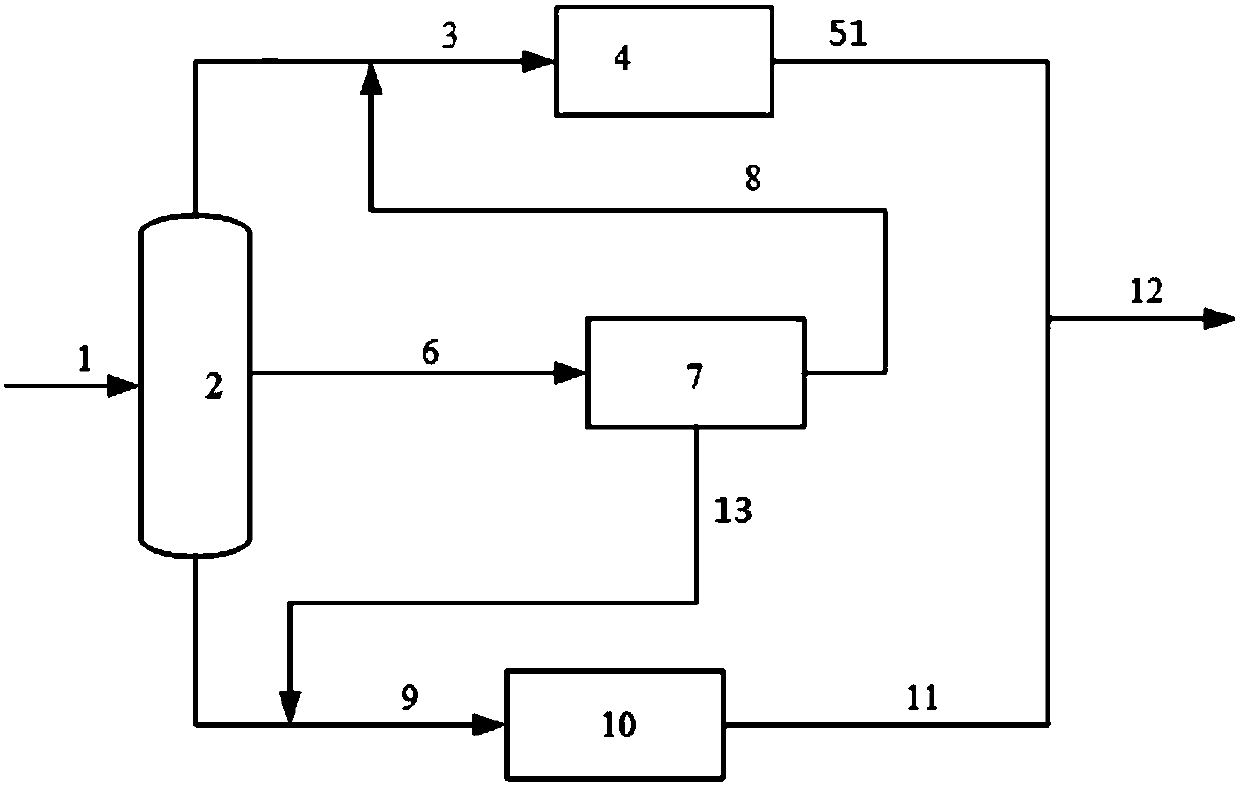

[0118] This embodiment adopts figure 2 The process shown in Table 1 desulfurizes gasoline feedstock E. The gasoline raw material E is a kind of catalytic cracking gasoline.

[0119] Gasoline raw material E is first cut into light fraction, middle fraction and heavy fraction in the fractionating tower, wherein the cut point temperature of the light fraction and the middle fraction is 60°C, the cut point temperature of the middle fraction and the heavy fraction is 100°C, and the light fraction The yield was 25% by weight, the yield of the middle fraction was 30% by weight, and the yield of the heavy fraction was 45% by weight.

[0120] In the solvent extraction unit, the middle fraction is subjected to solvent extractive distillation in a solvent extraction column:

[0121] In the solvent extraction tower: the feed weight ratio of poor solvent to middle distillate is 3:1, the temperature at the bottom of the tower is 170°C, the temperature at the top of the tower is 80°C, the...

Embodiment 2

[0134] This embodiment adopts figure 2 The process flow shown is for desulfurization treatment of the gasoline feedstock F in Table 1. The gasoline feedstock F is a catalytic cracking gasoline.

[0135] The gasoline raw material F is first cut into light fraction, middle fraction and heavy fraction in the fractionating tower, wherein the cut point temperature of the light fraction and the middle fraction is 60°C, the cut point temperature of the middle fraction and the heavy fraction is 120°C, and the light fraction The yield was 25% by weight, the yield of the middle fraction was 35% by weight, and the yield of the heavy fraction was 40% by weight.

[0136] In the solvent extraction unit, the middle fraction is subjected to solvent extractive distillation in a solvent extraction column:

[0137] In the solvent extraction tower: the feed weight ratio of poor solvent to middle distillate is 4:1, the temperature at the bottom of the tower is 150°C, the temperature at the top ...

Embodiment 3

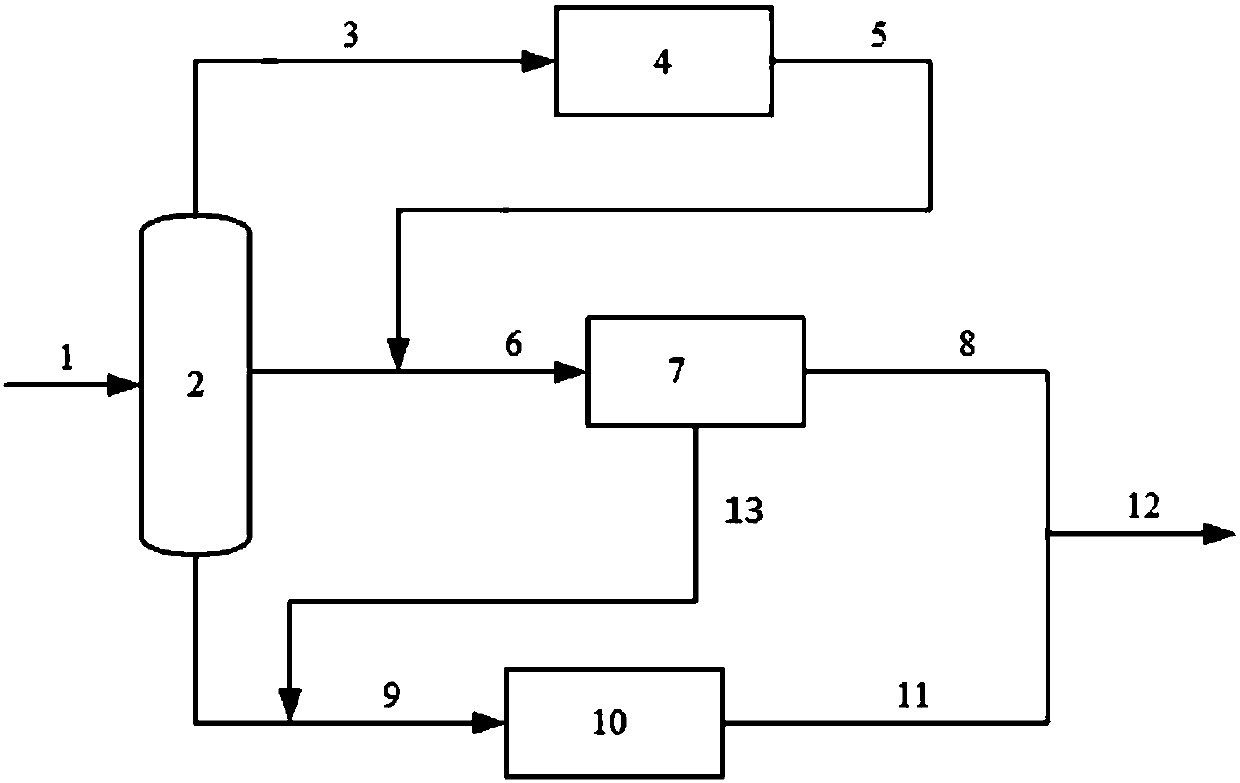

[0150] This embodiment adopts figure 1 The process shown in Table 1 desulfurizes the gasoline feedstock G. The gasoline raw material G is a kind of catalytic cracking gasoline.

[0151] Gasoline raw material G is first cut into light fraction, middle fraction and heavy fraction in the fractionating tower, wherein the cut point temperature of light fraction and middle fraction is 100°C, the cut point temperature of middle fraction and heavy fraction is 120°C, and the light fraction The yield was 50% by weight, the yield of the middle fraction was 15% by weight, and the yield of the heavy fraction was 35% by weight.

[0152] In the alkali cleaning unit, the volume ratio of the mixed fraction formed by the light distillate and raffinate is 8:2 when in contact with the lye, the temperature is 30°C, and the pressure is 0.6MPa to obtain the sweetened light distillate.

[0153] In the solvent extraction unit, the sweetened light and middle fractions are subjected to solvent extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com