Production method of isatin

A production method, the technology of isatin, is applied in the direction of organic chemistry to achieve the effect of increasing the treatment capacity and reducing the amount of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

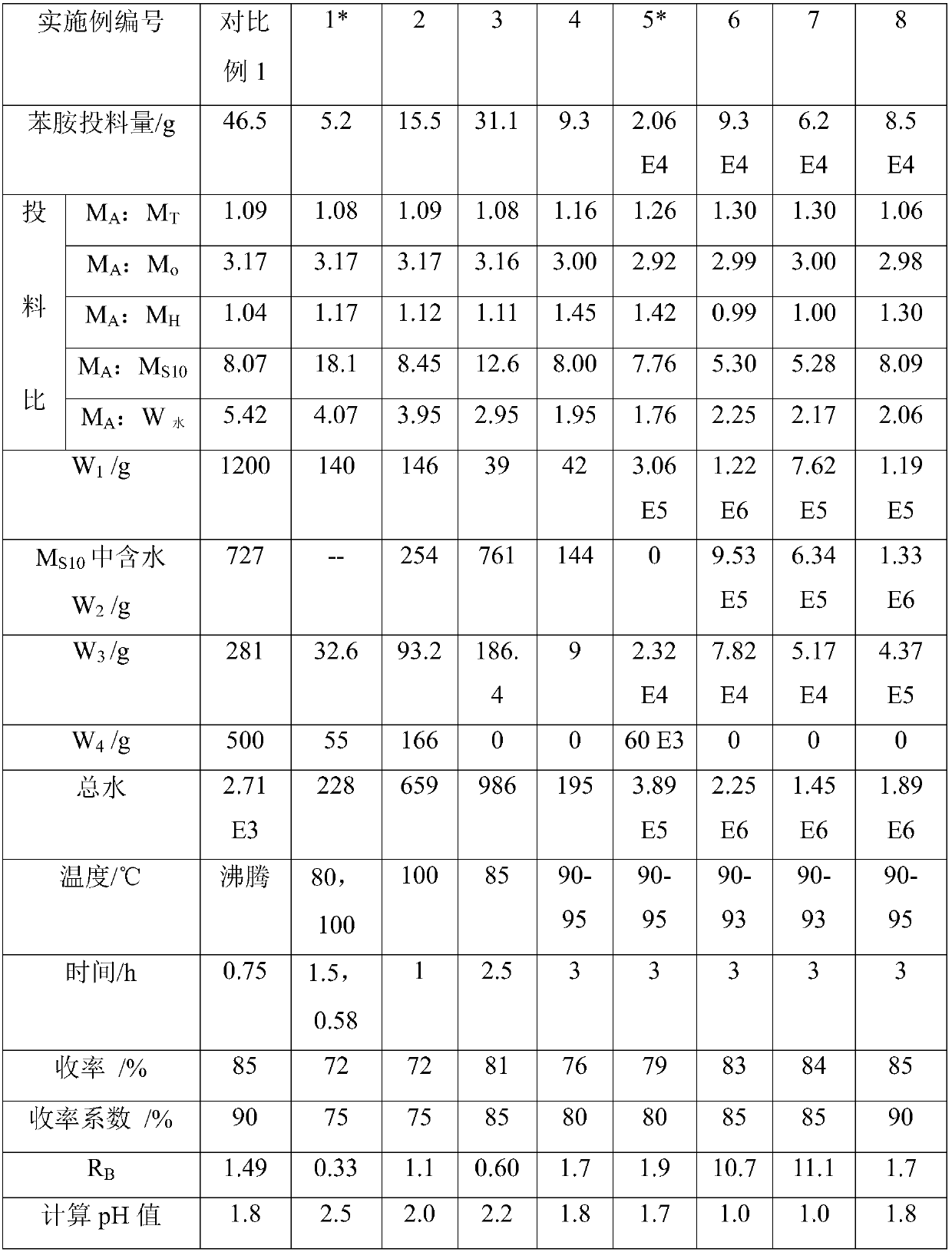

Examples

Embodiment 10

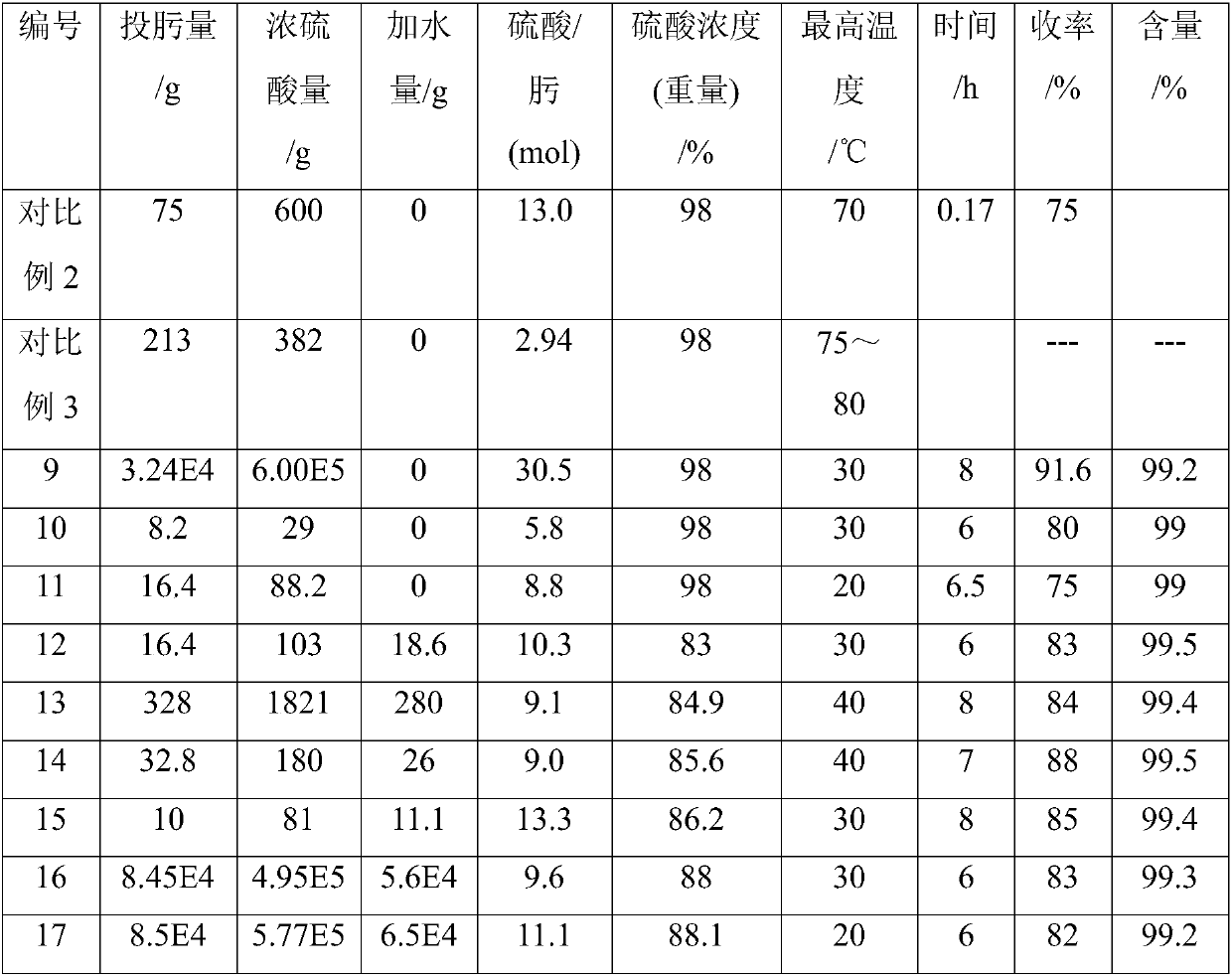

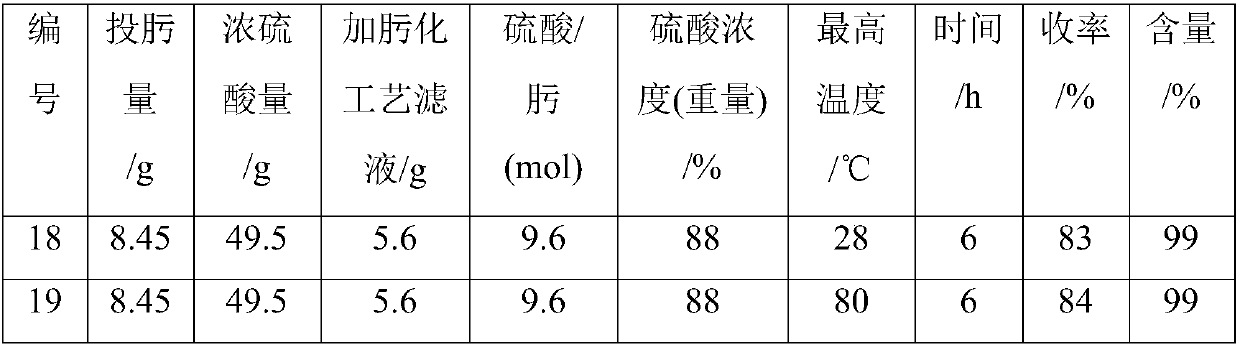

[0087] Example 10 is leaching with crushed ice; Example 12 and Example 13 are leaching with -8°C supercooled water; Example 11 is leaching with -14°C supercooled water, and there is no significant difference in the yield and amount of isatin, but In the treatment capacity of kilomole level, the ice-breaking process can be exempted, and supercooled water is preferred. In order to use supercooled water in the closed-loop process, it is advisable to establish a supporting filtrate process for recovering the process.

[0088] As can be seen from the embodiment of the closed-loop process in Table 2: (1) Reducing the reaction temperature or reducing the concentration of sulfuric acid can improve the safety of the process, which is different from the closed-loop reaction reported in the above-mentioned literature, and improves the safety of the closed-loop reaction to prolong the reaction time , in exchange for reducing the double safety factor of reaction temperature and reaction su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com