Track bed sound-absorbing plate and preparation method thereof

A technology of sound-absorbing panels and ballast beds, which is applied to tracks, roads, ceramic products, etc., can solve problems such as unsatisfactory noise reduction effect, achieve good water permeability, ensure sound absorption effect, and good sound absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings of the description.

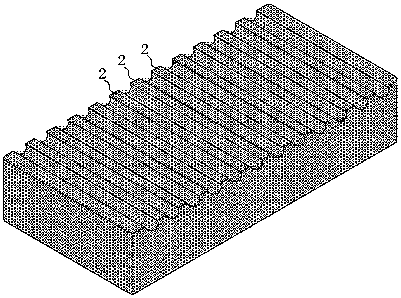

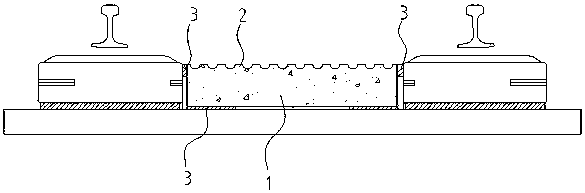

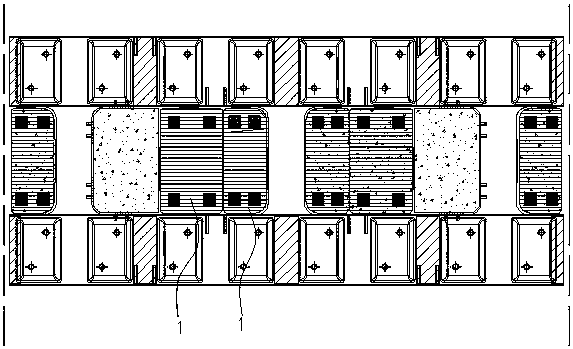

[0029] Such as Figures 1 to 3 As shown, a track bed sound-absorbing panel includes a main body 1 and several wedges 2 arranged on the top surface of the main body 1 and distributed along the longitudinal direction. The main body and the wedges 2 are integrally pressed and formed, and the height of the wedges 2 is 4cm. The thickness of the entire sound-absorbing panel is 175mm. The research shows that the sound-absorbing effect and material consumption of the 175mm-thick sound-absorbing panel are more reasonable, that is, it meets the sound-absorbing standard, and the cost is lower.

[0030] The material of the sound-absorbing board mainly includes ceramsite aggregate and cement gelling, and the ash-set ratio is 0.3-0.5. Because the most appropriate ratio is adjusted according to different materials, more cement, higher strength, lower porosity, poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com