Sealing device for gas cylinder or cylindrical vessel marshalling unit of compressed natural gas (CNG) carrier and marshalling unit

A technology of sealing device and transport ship, which is applied in the direction of preventing the multi-way movement of goods, for bulk goods, etc., can solve the problems of increasing the risk of system leakage and increasing the cost, reducing costs and leakage points, improving safety, The effect of ensuring system security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

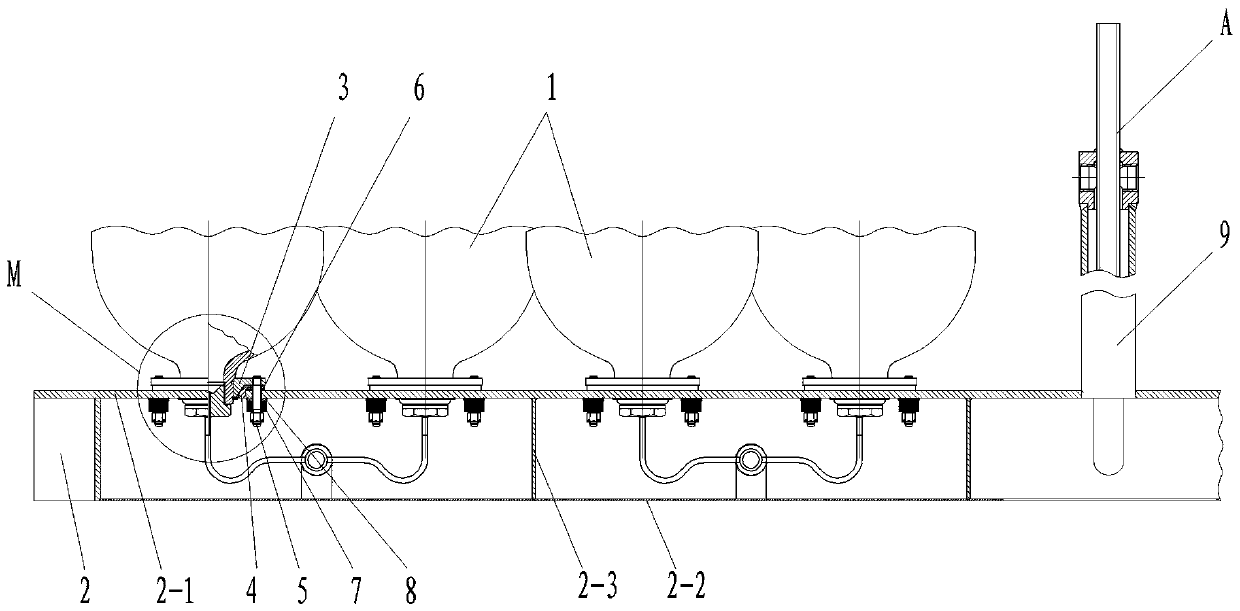

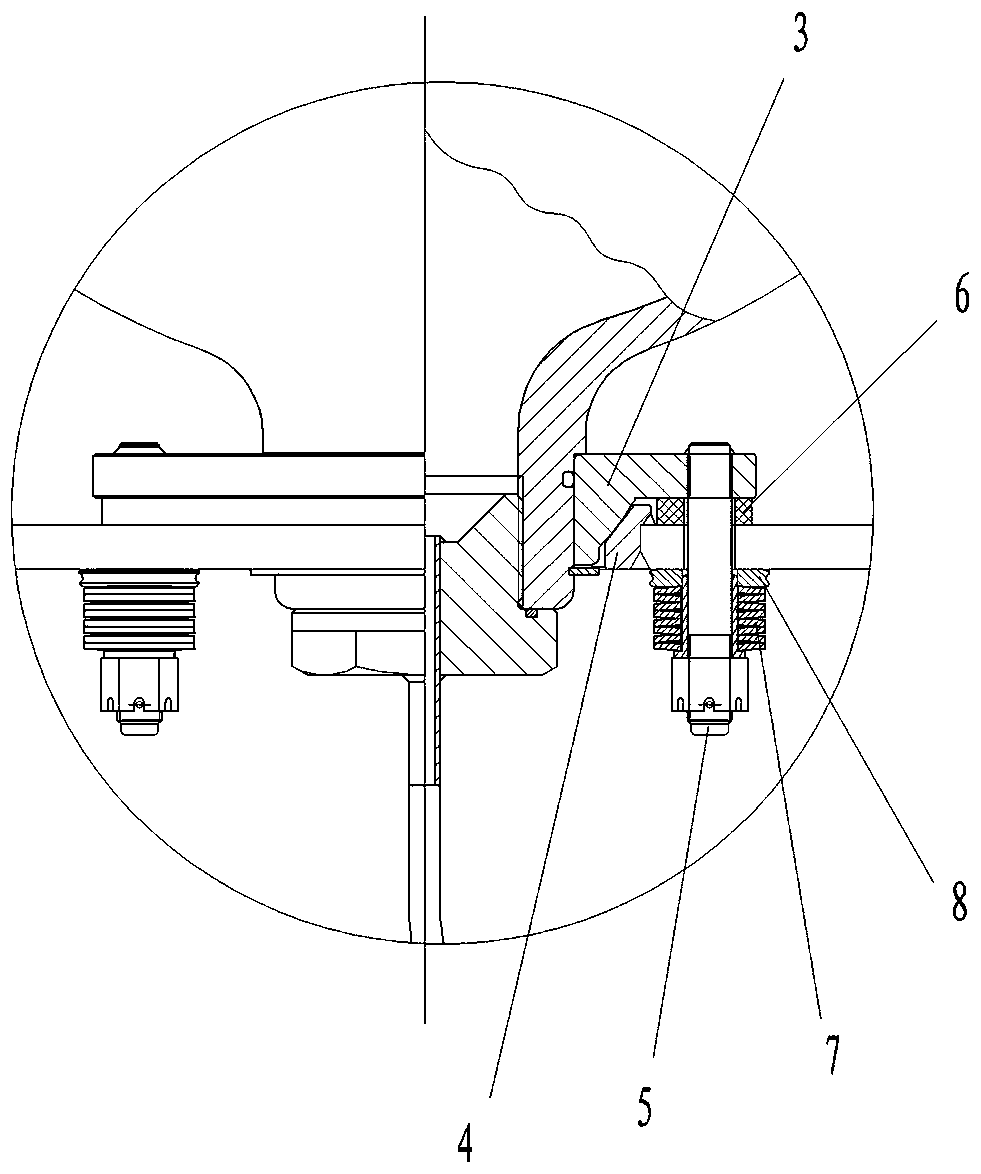

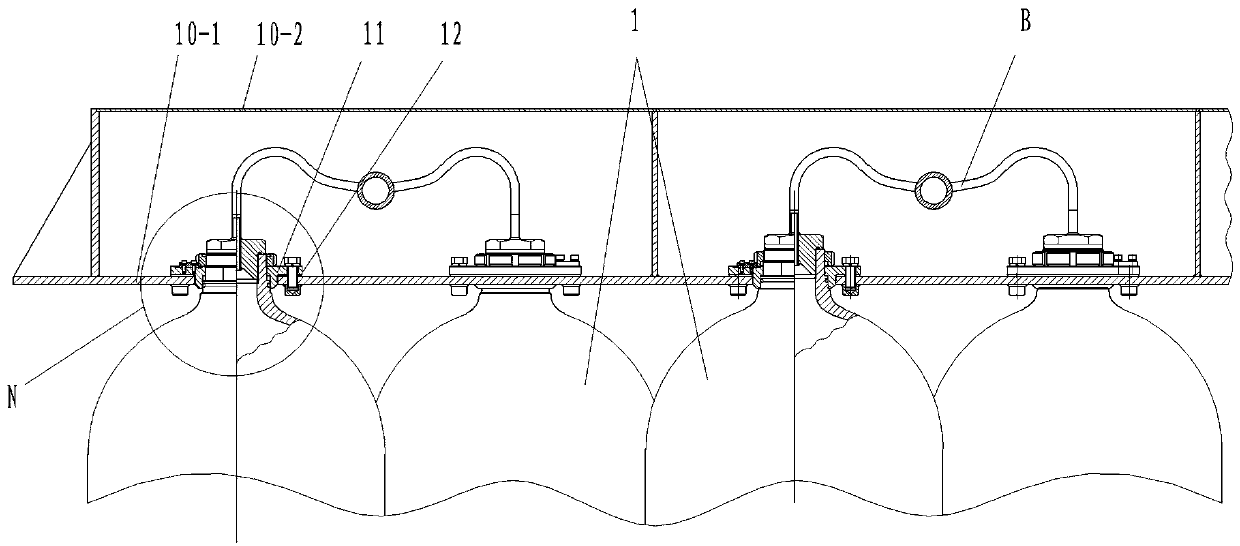

[0033] See attached Figure 6 , the present invention provides a sealing device for a CNG carrier gas cylinder or a bottle-type container grouping unit, which is arranged on the bottom and / or top of a gas cylinder or a bottle-type container grouping unit in a CNG carrier natural gas storage system, the key lies in: including The blowdown pipeline sealing box 2 connected with the bottom of each gas cylinder or bottle container 1 in the gas cylinder or bottle container grouping unit and filled with protective gas and / or with each gas cylinder or bottle in the gas cylinder or bottle container grouping unit The top of the container 1 is connected to the loading and unloading gas pipeline sealing box 10 filled with protective gas; the sewage pipeline A is located in the sewage pipeline sealing box 2, and the control valve matched with the sewage pipeline A is located in the gas cylinder or bottle container Outside the grouping unit, the loading and unloading gas pipeline B is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com