Thermoplastic prepreg and preparation method thereof

A prepreg, thermoplastic technology, used in the field of composite material manufacturing, can solve the problems that hinder the rapid manufacture of composite material parts in a wide range of applications in the aerospace field, it is difficult to achieve close adhesion between layers, control the direction of fiber layup, and difficult to plastic deformation. and bending problems, to achieve the effect of improving stiffness, easy laying, and reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

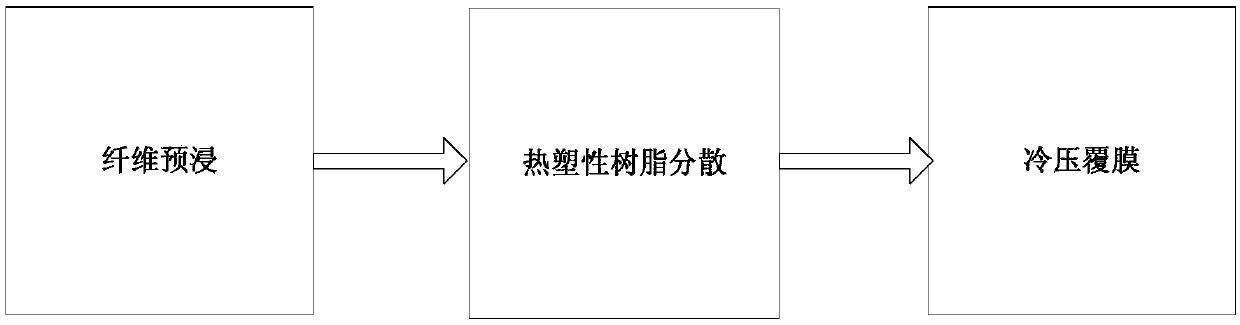

[0034] Step 1, use the solution method to make the areal density to 135g / m 2 Carbon fiber is pre-impregnated with thermosetting resin polyimide, forming a continuous adhesive resin film on both sides of the carbon fiber; in the obtained material, the resin weight content is 10% of the carbon fiber, and the processing temperature is room temperature;

[0035] Step 2, at room temperature, evenly paint the PPS powder with a diameter of 20 μm on the surface of the thermosetting resin on both sides of the carbon fiber,

[0036] In step 3, the material obtained in step 2 is cold-pressed, coated, and rolled;

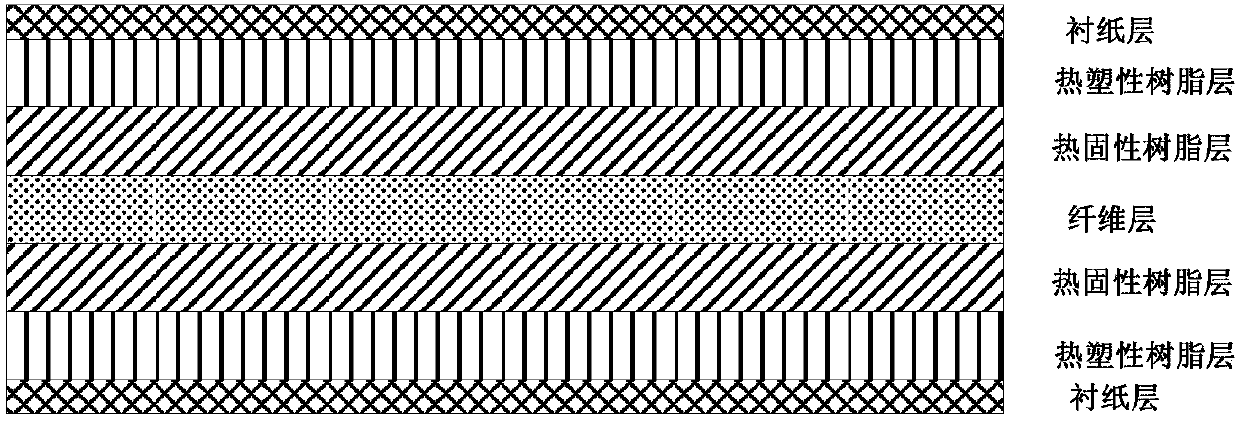

[0037] A structural example of the thermoplastic prepreg is shown in figure 1 shown.

[0038] During the preparation process of the prepreg, it only needs to be operated at room temperature and does not require high-temperature melting of thermoplastic resins, which not only reduces the energy consumption of the preparation, saves costs, but also prevents the performance of t...

Embodiment 2

[0040] Step 1, use the solution method to make the areal density 130g / m 2 Carbon fiber is pre-impregnated with thermosetting resin polyimide, forming a continuous adhesive resin film on both sides of the carbon fiber; in the obtained material, the resin weight content is 15% of the carbon fiber, and the processing temperature is room temperature;

[0041] Step 2, at room temperature, evenly paint PEEK powder with a diameter of 10 μm on the surface of the thermosetting resin on one side of the carbon fiber;

[0042] In step 3, the material obtained in step 2 is cold-pressed, coated, and rolled;

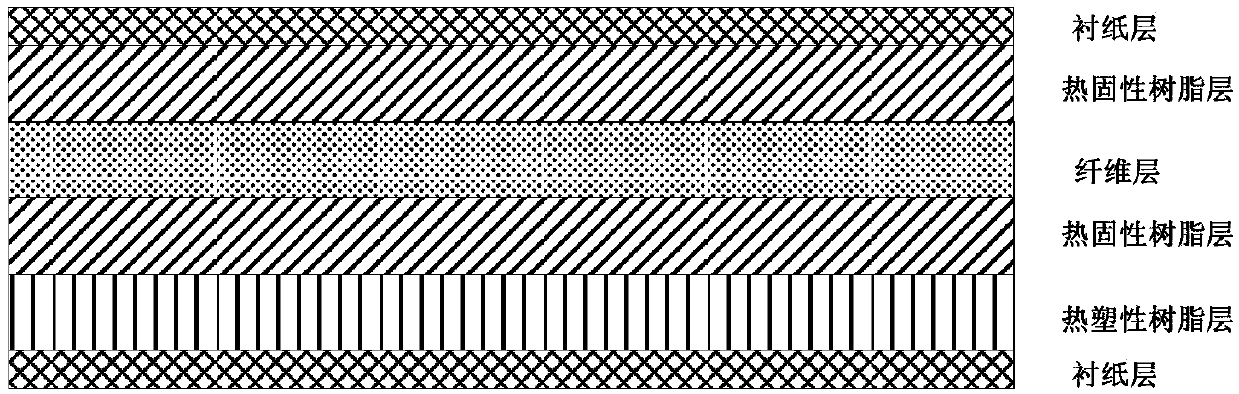

[0043] A structural example of the thermoplastic prepreg is shown in figure 2 shown.

[0044] During the preparation process of the prepreg, it only needs to be operated at room temperature and does not require high-temperature melting of thermoplastic resins, which not only reduces the energy consumption of the preparation, saves costs, but also prevents the performance of the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com