Device and method for cleaning and disinfecting waste beer bottles

A technology for cleaning and disinfecting beer bottles, which is applied in the direction of disinfection, water supply equipment, and drying gas arrangement, etc., can solve the problems of uneven and incomplete disinfection, and low working efficiency of disinfection equipment, and achieve uniform and thorough disinfection, reasonable design, and ingenious conception Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

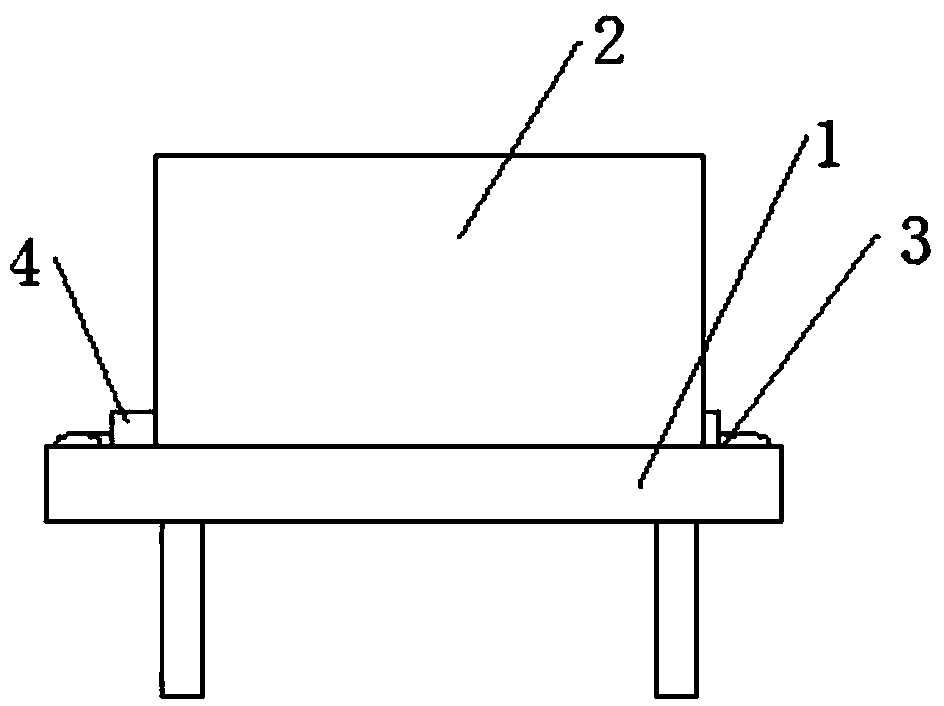

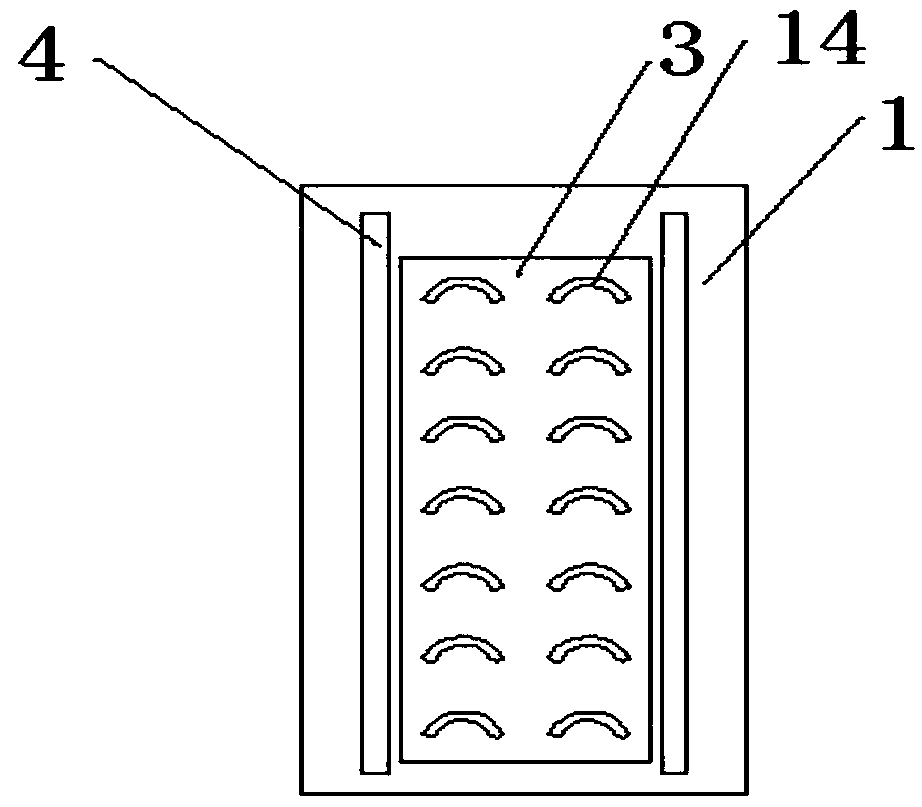

[0023] see Figure 1-4 , the present invention provides a technical solution: a novel beer bottle disinfection device, comprising a workbench 1, a disinfection chamber 2 and a conveyor belt 3, the conveyor belt 3 is embedded and installed on the upper surface of the workbench 1, and the disinfection chamber 2 is arranged directly above the conveyor belt 3 and is fixedly welded with the workbench 1, and a vertically downward partition plate 5 is fixedly arranged in the middle of the inner cavity of the disinfection chamber 2, and the partition plate 5 separates the disinfection chamber 2 Divided into a drying chamber 6 and a cooling chamber 7, the top of the inner wall of the drying chamber 6 is fixedly welded with a vertically downward inverted T-shaped fixing frame 8, and multiple The drying nozzle 9 is inclined downward, and the drying nozzle 9 is inclined downward by 75 degrees, which is convenient for blowing hot air into the beer bottle. The blower fan 10 communicates wi...

Embodiment 2

[0026] see Figure 1-4 , the present invention provides a technical solution: a novel beer bottle disinfection device, comprising a workbench 1, a disinfection chamber 2 and a conveyor belt 3, the conveyor belt 3 is embedded and installed on the upper surface of the workbench 1, and the disinfection chamber 2 is arranged directly above the conveyor belt 3 and is fixedly welded with the workbench 1, and a vertically downward partition plate 5 is fixedly arranged in the middle of the inner cavity of the disinfection chamber 2, and the partition plate 5 separates the disinfection chamber 2 Divided into a drying chamber 6 and a cooling chamber 7, the top of the inner wall of the drying chamber 6 is fixedly welded with a vertically downward inverted T-shaped fixing frame 8, and multiple The drying nozzle 9 is inclined downward, and the drying nozzle 9 is inclined downward by 75 degrees, which is convenient for blowing hot air into the beer bottle. The blower fan 10 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com