Rolling folding mechanism

A rolling and rolling technology, applied in the field of rolling mechanism of battery plastic film, can solve problems such as low efficiency, unguaranteed safety, inconsistent battery edges, etc. flat effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

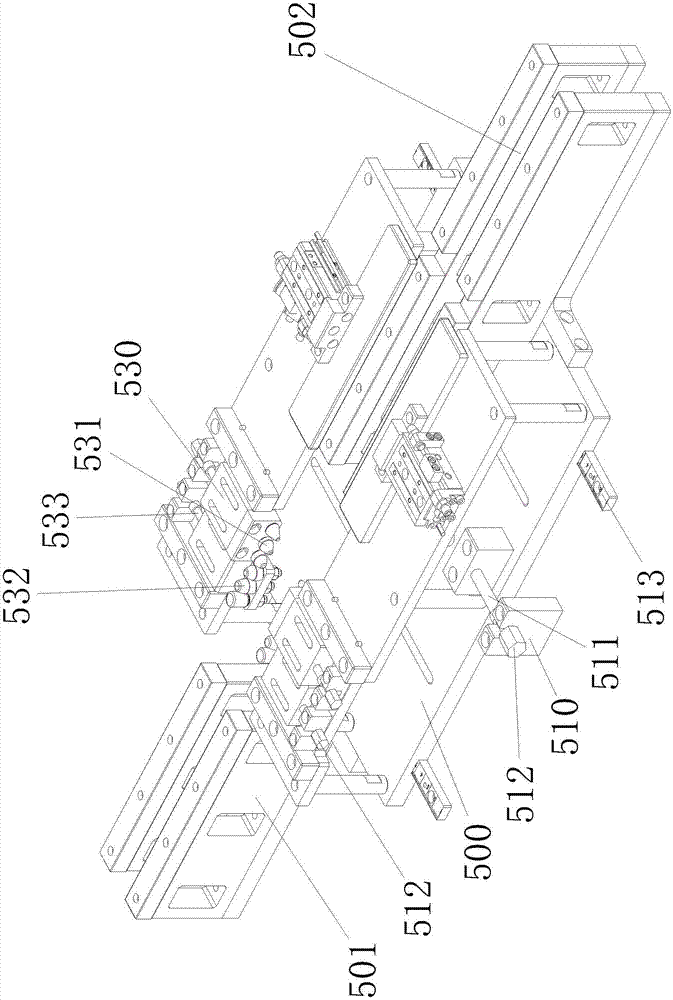

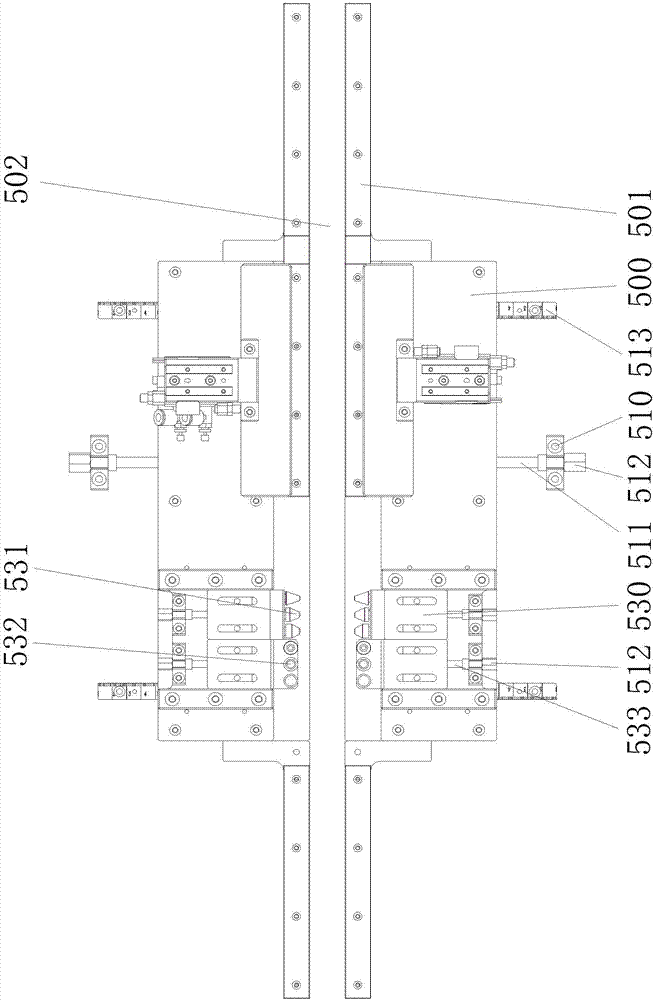

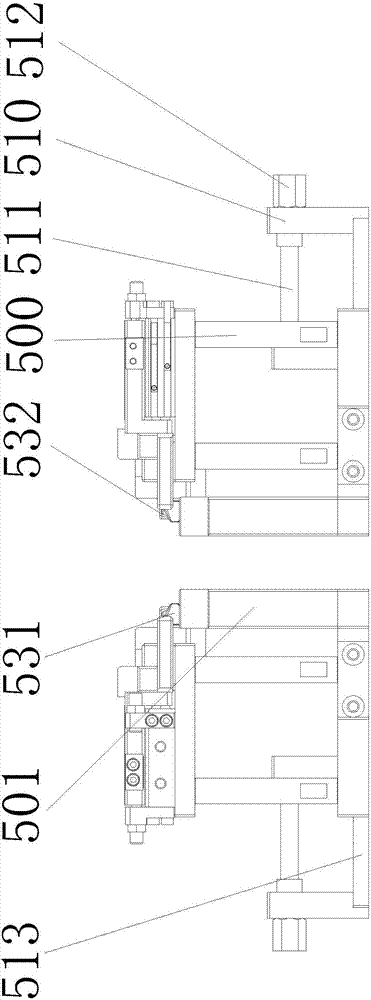

[0027] refer to Figure 1 ~ Figure 3 As shown, the present invention discloses a rolling mechanism, including a rolling base (not shown in the figure) and a rolling support 500 arranged thereon, and a rolling support 501 is provided with a rolling support 501 . Both the rolling bracket 500 and the rolling platform 501 have two groups, which are mirror images of each other. There is a rolling channel 502 between the two rolling platforms 501 , and the rolling bracket 500 can slide away from or toward the rolling channel 502 .

[0028] An adjusting and fixing block 510 is arranged on the above-mentioned rolling base, an adjusting screw 511 is arranged on the above-mentioned rolling bracket 500 , and the other end of the adjusting screw 511 is arranged on the adjusting and fixing block 510 . An adjustment knob 512 is provided on the adjustment screw 511 . Turning the adjusting knob 512 can slide the rolling bracket 500 to change the width of the rolling channel 502 to adapt to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com