Green light organic electroluminescence device

A luminescent and electromechanical technology, applied in the field of organic electroluminescent devices, can solve the problems of high doping concentration, high cost, and low energy of the green OLED light-emitting layer, so as to improve device efficiency and life, improve efficiency, and improve excitation The effect of sub-utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

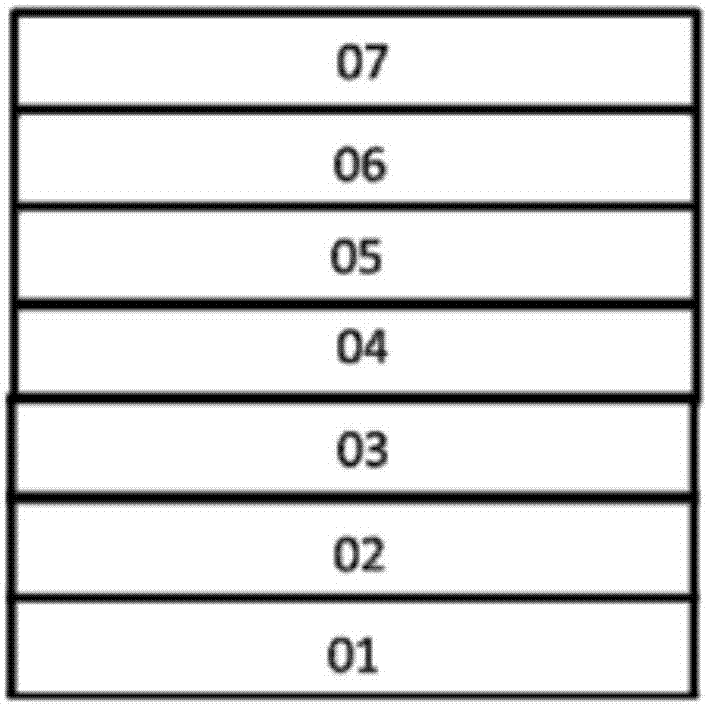

[0070] like image 3 As shown, a green organic electroluminescent device provided by the present invention includes a substrate, and a first electrode layer 01, a light emitting layer 04, and a second electrode layer 07 sequentially formed on the substrate, the first electrode A first organic functional layer is arranged between the layer 01 and the light-emitting layer 04 , and a second organic functional layer is arranged between the light-emitting layer 04 and the second electrode layer 07 . The first organic functional layer is the hole injection layer 02 and / or the hole transport layer 03 , and the second organic functional layer is the electron transport layer 05 and / or the electron injection layer 06 .

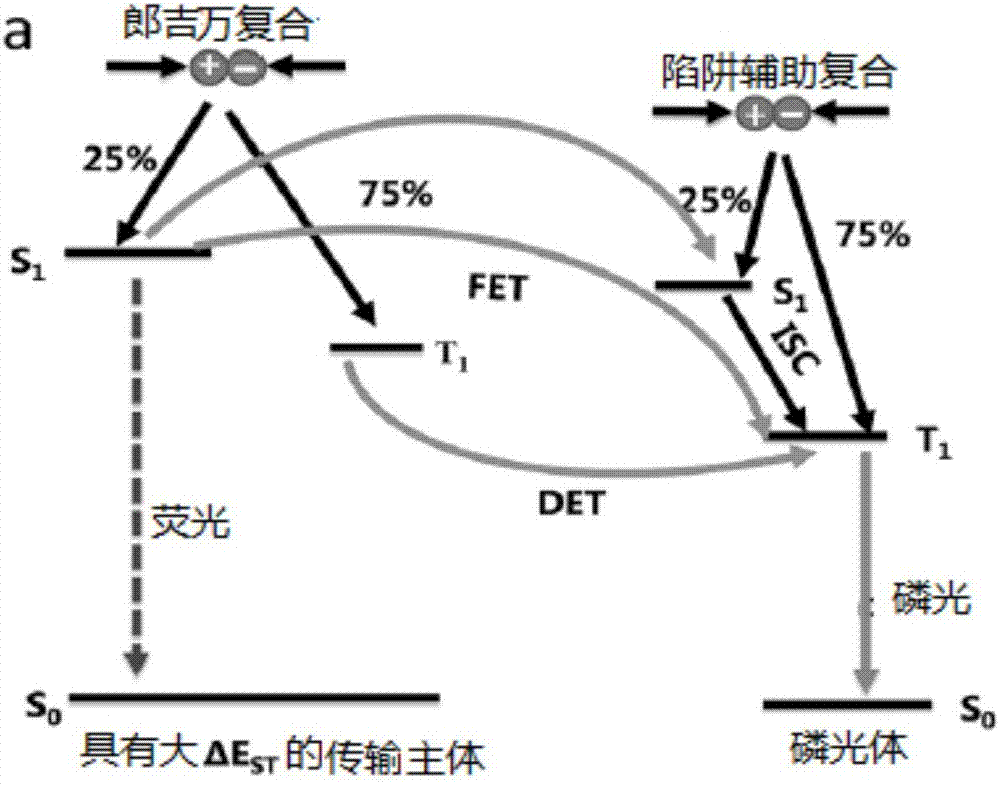

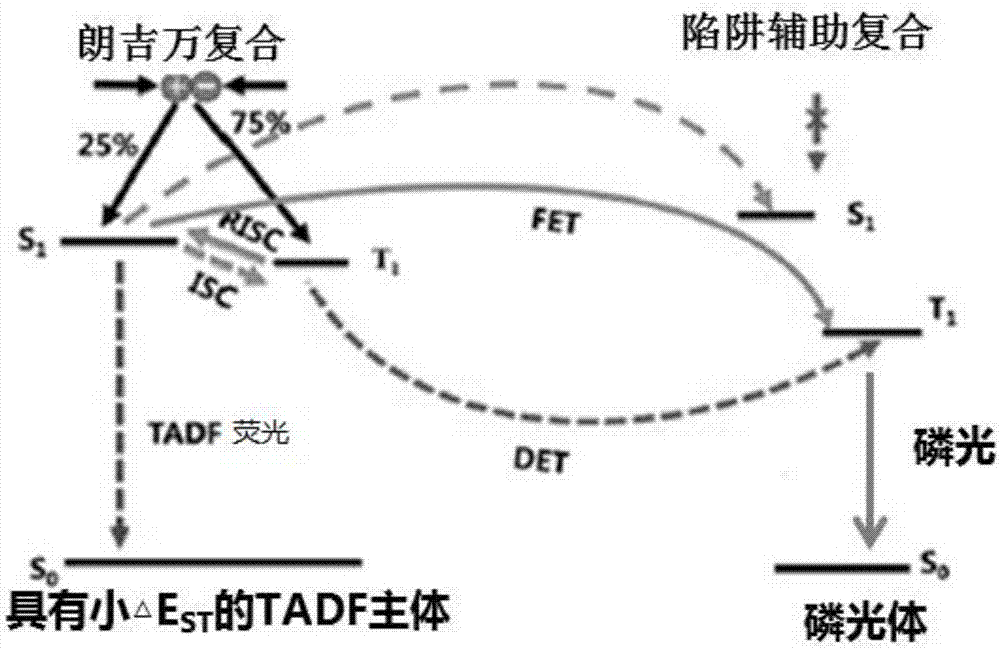

[0071] The light-emitting host material of the device in this embodiment is a thermally activated delayed fluorescent material and a hole-type transport material doped or not doped with a hole-type transport material, and the mass ratio of the thermally activated delaye...

Embodiment 2

[0081] The structures of the light-emitting devices from device 2 to device 5 are the same as those of device 1, except that the doping concentration of the green phosphorescent dye is different. Its structure is as follows:

[0082] ITO / NPB(40nm) / TCTA(10nm) / Formula 2-1: 0.5~5wt%Ir(ppy) 2 (acac)(20nm) / Bphen(40nm) / LiF(5nm) / Al

[0083] Table 3 Performance test results of device 2 to device 5

[0084]

[0085] The performance of light-emitting devices from device 2 to device 5 was tested, as shown in Table 3, at 5000cd / m 2 Under brightness, as the doping concentration of the dye increases, the current efficiency of the device also increases, because the long-range The energy transfer improves the exciton utilization, which in turn increases the device efficiency.

Embodiment 3

[0087] The structures of the light-emitting devices from device 6 to device 10 are the same as those of the light-emitting device in Embodiment 1, except that the host material of the light-emitting layer 06 is different. Its structure is as follows:

[0088] ITO / NPB(40nm) / TCTA(10nm) / host material: 3wt%Ir(ppy) 2 (acac)(20nm) / Bphen(40nm) / LiF(5nm) / Al

[0089] Table 4 Performance test results of device 6 to device 10

[0090]

[0091]The performance of light-emitting devices from device 6 to device 10 was tested, as shown in Table 4, at 5000cd / m 2 Under the brightness, different thermally activated delayed fluorescent materials and different hole-type transport materials were co-evaporated. Although the doping ratios were different, the device performance showed low driving voltage and high efficiency, indicating that the thermally activated delayed Fluorescence: The host material composed of hole-transport materials is universal, and its devices have high-efficiency perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com