Automatic detection device for M-value of worm and runout of tooth surface

An automatic detection device and worm technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem that the M value of the worm and the runout of the tooth surface cannot be judged as a whole, whether the worm curve is consistent, and the accuracy of the M value measurement cannot be judged. To avoid the risk of manual error and missed detection, the structure and setting method are novel, and the measurement force is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

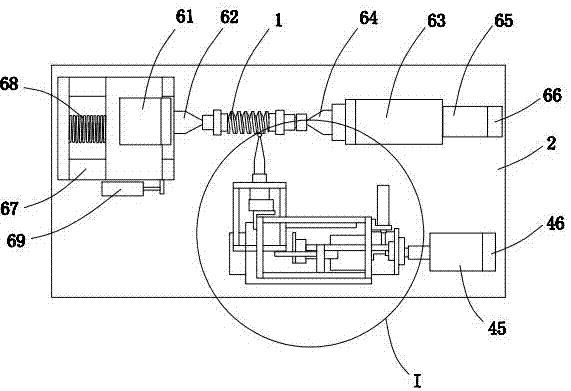

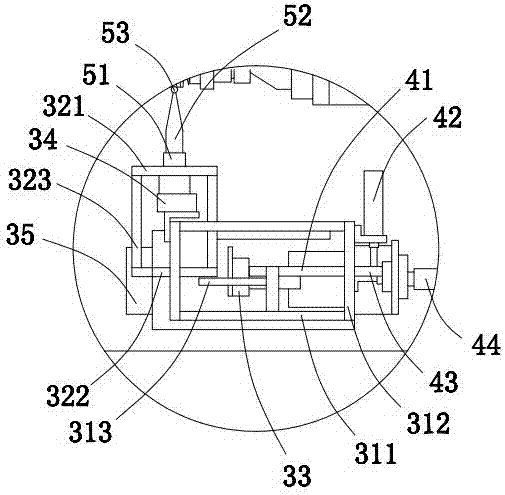

[0025] Such as figure 1 The automatic detection device for the M value and tooth surface runout of the worm shown includes a worktable 2 on which a clamping unit for clamping the worm and a measuring unit for measuring the worm M value and tooth surface runout are provided, The measurement unit includes a contact part, a measurement part, a mobile base and a measurement control part. The contact part is connected to the measurement part. The measurement part is arranged on the mobile base 35. The measurement control part is connected to the mobile base 35. The measurement control part can control the measurement part and the contact. The part moves in the direction parallel to the clamping axis of the worm 1 and the radial direction of the worm, so that the contact part is in contact with the worm tooth surface for measurement.

[0026] This embodiment aims to measure the M value and tooth surface runout of the worm 1 by flexibly controlling the movement of the measuring part and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com