FDS bottom plate thickness judgment method and device, electronic equipment and storage medium

A judgment method and the technology of the bottom plate, which are applied in the fields of commerce, instruments, and data processing applications, etc., can solve the problems of incomplete inspection, high production cost, and inability to measure the thickness of the bottom plate, so as to avoid missed inspections and reduce inaccurate The pass rate and repair rate, and the effect of avoiding scrapping the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

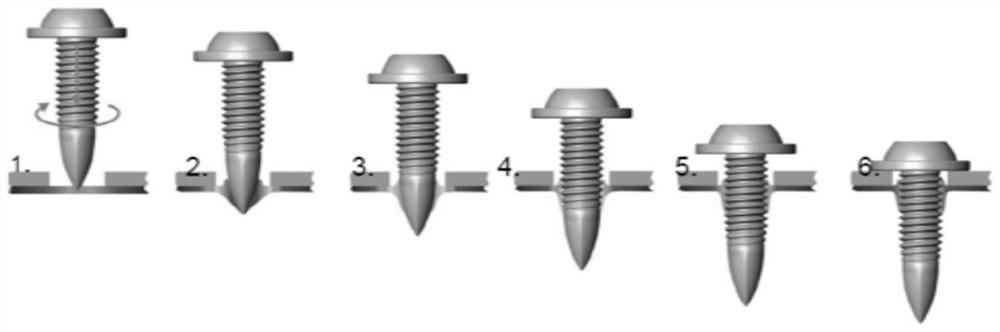

[0031] The present invention is applied in the flow drill screw tightening process (abbreviated as FDS in English).

[0032] The method for judging the thickness of the FDS bottom plate of the present invention includes a plurality of steps S1-S4, below in conjunction with reference to the attached image 3 Each step is described in detail.

[0033] Setting step S1, setting the standard value of the base plate thickness corresponding to each point on the vehicle body.

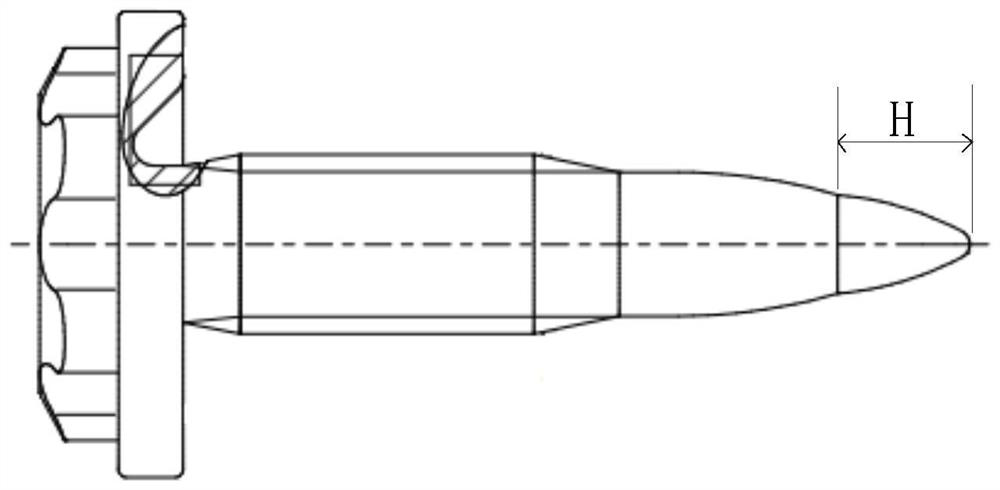

[0034] Acquisition step S2, obtaining the screw point length data of the FDS connecting screw and collecting the data information of the FDS device in the working process in real time. The position data at the maximum pressure of the stage, and the point number.

[0035] Processing step S3, according to the length data of the screw tip, the position data of the screw tip when it touches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com